Comprehensive utilization method of waste acid, caustic sludge and dedusting ash

A technology for alkali residue and waste residue, applied in the field of resource recycling, can solve the problems of inability to recover various valuable metals and pollution of the surrounding environment, and achieve the effects of reducing environmental burden, avoiding pollution, and avoiding redissolution reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

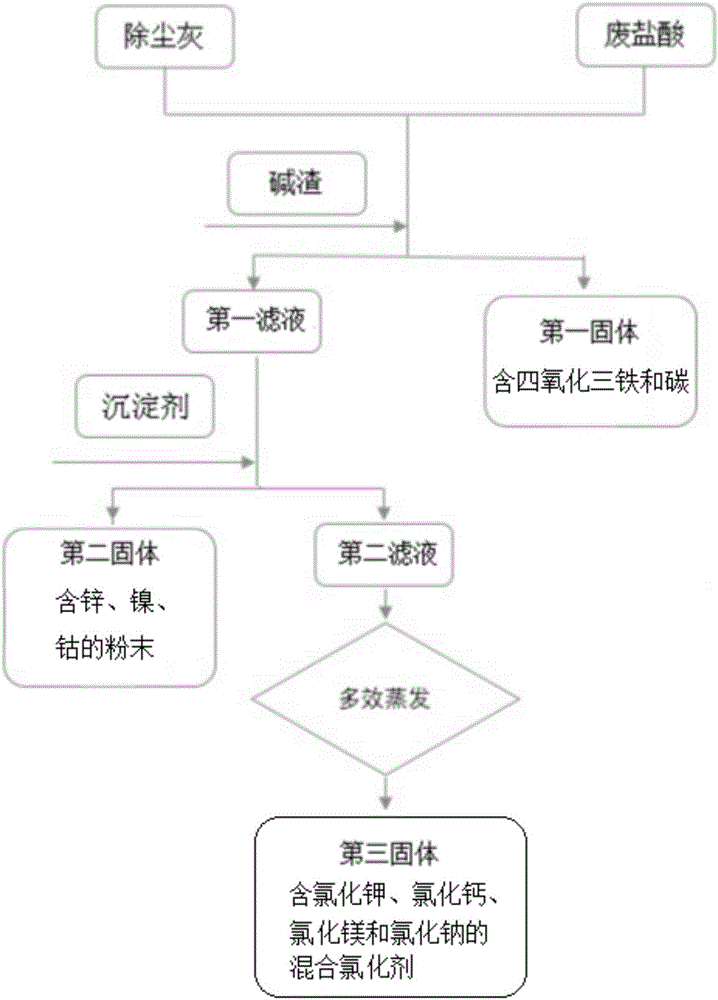

[0029] A comprehensive utilization method of waste acid, alkali slag and dedusting ash, see figure 1 , including the following steps:

[0030](1) Mix dust removal ash and waste hydrochloric acid at a solid-to-liquid ratio of 1g: 6mL, and stir for 70min at 50°C at a stirring rate of 120r / min;

[0031] (2) adding alkali residue to the liquid obtained in step (1) to make the mass fraction of alkali residue be 85%, stirring and controlling the pH value at 8, reacting for 50min, filtering and separating to obtain the first solid (containing trioxide) solids of iron and carbon) and the first filtrate;

[0032] (3) The precipitating agent is added to the first filtrate to make the mass fraction of the precipitating agent 2.5%, stirred for 70min, filtered and separated to obtain the second solid (powder containing zinc, nickel, cobalt) and the second filtrate, the second filtrate The third solid (a mixed chlorinating agent containing potassium chloride, calcium chloride, magnesium c...

Embodiment 2

[0036] A comprehensive utilization method of waste acid, alkali slag and dedusting ash, comprising the following steps:

[0037] (1) Mix dust removal ash and waste hydrochloric acid at a solid-to-liquid ratio of 1g:4mL, and stir for 60min at 80°C at a stirring rate of 180r / min;

[0038] (2) adding alkali residue to the liquid obtained in step (1) to make the mass fraction of alkali residue be 80%, stir and control the pH value at 7.5, react for 60min, and filter and separate to obtain the first solid (containing trioxide) solids of iron and carbon) and the first filtrate;

[0039] (3) precipitating agent is joined in the first filtrate to make the massfraction of precipitating agent be 2%, stir 80min, filter and separate, get the second solid (powder containing zinc, nickel, cobalt) and the second filtrate, the second filtrate The third solid (a mixed chlorination agent containing potassium chloride, calcium chloride, magnesium chloride and sodium chloride) was obtained throu...

Embodiment 3

[0043] A comprehensive utilization method of waste acid, alkali slag and dedusting ash, comprising the following steps:

[0044] (1) Mix dust removal ash and waste hydrochloric acid at a solid-to-liquid ratio of 1g: 8mL, and stir for 90min at 40°C at a stirring rate of 100r / min;

[0045] (2) adding alkali slag to the liquid obtained in step (1) so that the mass fraction of alkali slag is 90%, stir and control the pH value at 8.5, react for 40min, filter and separate, get the first solid (containing trioxide) solids of iron and carbon) and the first filtrate;

[0046] (3) precipitating agent is joined in the first filtrate to make the massfraction of precipitating agent be 3%, stir 60min, filter and separate, get the second solid (powder containing zinc, nickel, cobalt) and the second filtrate, the second filtrate The third solid (a mixed chlorination agent containing potassium chloride, calcium chloride, magnesium chloride and sodium chloride) was obtained through evaporation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com