Spray nozzle of nanofiber mass production device

A nanofiber, mass production technology, applied in fiber processing, textile and papermaking, filament/thread forming, etc., can solve the problems of difficult cleaning, easy blocking, easy volatilization of organic solvents, etc., achieve uniform texture, overcome easy blocking, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

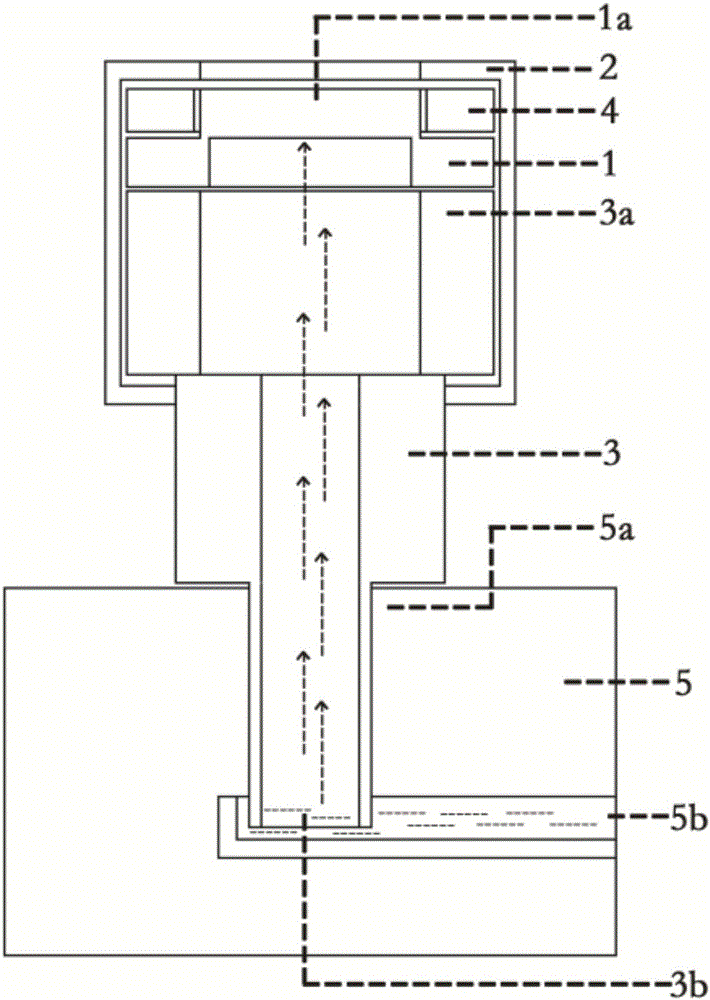

[0021] The structure of the nozzle of the nanofiber mass production device is: the convex part of the polytetrafluoroethylene convex porous plate is covered with a fluorine rubber sealing pressure ring, which is placed on the open nozzle end of the stainless steel nut nozzle body, and its flat part faces the stainless steel nut nozzle The threaded end of the body; the large mouth end and the small mouth end of the stainless steel hollow T-shaped outer spiral tube each have an outer spiral, which can be connected with the threaded end of the stainless steel nut nozzle body and the connection port of the stainless steel liquid tank in a spiral manner, so that the PTFE The vinyl convex porous plate is tightly fixed between the stainless steel nut nozzle body and the stainless steel hollow T-shaped outer spiral tube, and at the same time, the spinning solution pushed through the liquid inlet of the stainless steel liquid tank by the air pump or electric pump can pass through the sta...

Embodiment 2

[0028] The structure of the nozzle of the nanofiber mass production device is the same as that in Example 1, and the diameter of the spinneret pores on the surface of the convex part of the polytetrafluoroethylene convex porous plate 1 is 0.1 mm. The electrospinning solution is 10% polyethylene oxide aqueous solution, the air pump propulsion speed is 0.1 mL / min, the spinning voltage is 20 Kv, and the collection distance is 16 cm. Five nozzles work at the same time, the average diameter of the prepared nanofibers is 300nm, the size of the nanofiber film obtained in 15 minutes is 40×40cm, and the thickness is 150μm.

Embodiment 3

[0030] The structure of the nozzle of the nanofiber mass production device is the same as in Example 1, the diameter of the spinneret pores on the surface of the convex part of the polytetrafluoroethylene convex porous plate 1 is 0.05 mm, and the electrospinning solution is 10% polystyrene dichloromethane solution, the electric pump propulsion speed is 0.2mL / min, the spinning voltage is 15Kv, and the collection distance is 15cm. The average diameter of the prepared nanofibers is 300nm under the working mode of a single nozzle, the size of the nanofiber film obtained in 20 minutes is 13×17cm, and the thickness is 90μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com