Ceramic nanofiber and preparing method and device thereof

A technology of nanofibers and ceramics, applied in the field of materials science and engineering, can solve the problems of difficult preparation, limited production and application of ceramic nanofibers, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

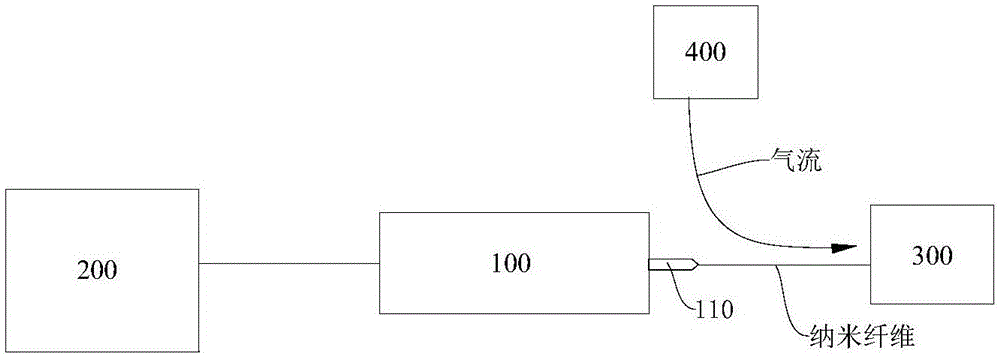

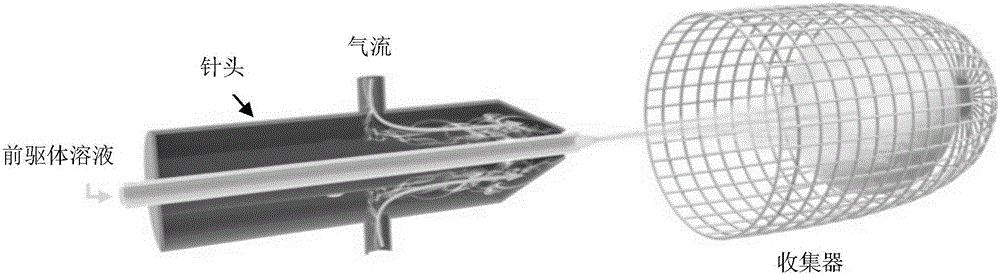

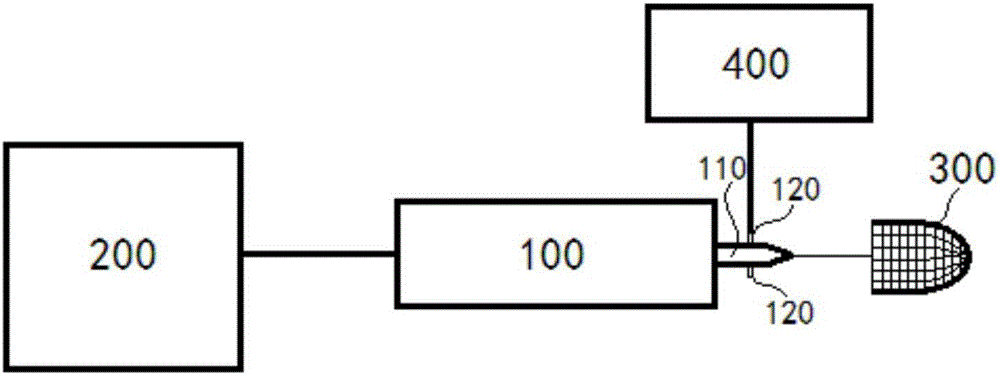

Method used

Image

Examples

Embodiment 1

[0086] In this example, titanium oxide nanofibers and their three-dimensional sponge structures were prepared.

[0087] The specific preparation method is as follows: first prepare the precursor solution, first mix the mixed solvent of acetic acid and ethanol with a mass ratio of 1:3, add tetrabutyl titanate and PVP with a mass ratio of 1:2, and mix The mass fraction of PVP in the obtained precursor solution was 7%; and the prepared precursor solution was passed through a sealed vial and stirred for 6 hours until the PVP was completely dissolved. Then, draw a certain amount of precursor solution into the syringe, and inject the precursor solution from the inner shaft of the coaxial needle at a speed of 3mL / h through the injection pump, while the airflow passes through the outer shaft of the needle at a speed of 21m / s , the precursor solution is stretched into fibers in the air, and the solvent is also rapidly volatilized, and finally nano-scale fibers are formed, which are col...

Embodiment 2

[0090] In this example, zirconia nanofibers and their three-dimensional sponge structures were prepared according to the same preparation method as in Example 1. The difference is that zirconium oxychloride (ZrOCl 2 ·8H 2 The mass ratio of O) and PVP is 2:1, the mass ratio of water and ethanol in the mixed solvent is 1:1, the mass fraction of PVP in the precursor solution is 8%, and the precursor solution is stirred at room temperature until the solute is completely dissolved ; The airflow passes through the outer axis of the needle at a speed of 18m / s, and the distance between the liquid outlet and the porous cage collector is 15cm; the sintering temperature is 800°C, and the holding time is 200min, and finally a zirconia nanometer with a diameter of 200nm to 300nm is obtained. Three-dimensional structure composed of fibers.

Embodiment 3

[0092] In this example, barium titanate nanofibers and their three-dimensional sponge structures were prepared according to the same preparation method as in Example 1. The difference is that barium acetate (Ba(Ac) 2 ) and tetrabutyl titanate at a mass ratio of 1:1, the solvent is ethanol, and the precursor solution is stirred at room temperature until the solute is completely dissolved; the precursor solution is injected from the inner shaft of the coaxial needle at a speed of 2.5mL / h , the airflow passes through the outer axis of the needle at a speed of 16m / s, and the distance between the liquid outlet and the porous cage collector is 16cm; the sintering temperature is 750°C, and the holding time is 60min, and finally a barium titanate nanometer with a diameter of about 300nm is obtained. Three-dimensional structure composed of fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com