Permeable paving system and paving method for removing oil stain in runoff rainwater

A permeable pavement, rainwater technology, applied in the direction of runoff/rainwater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve environmental pollution, has not been effectively solved, has not considered road runoff oil pollution, etc. problems, to achieve the effect of easy-to-hang biomass, prevent loss, and enrich micropores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

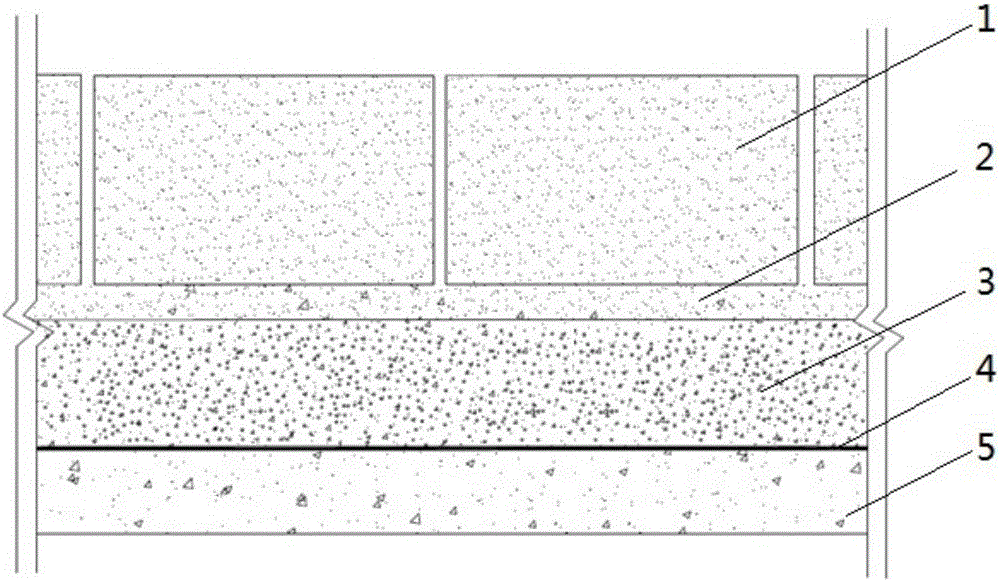

[0110] Embodiment 1, permeable pavement system

[0111] The structure of the permeable pavement system is divided into permeable brick layer, microbial layer, permeable geotextile layer and permeable base layer from top to bottom.

[0112] 1) Permeable layer

[0113] The permeable layer is composed of permeable bricks with a thickness of 40-80mm and a porosity of 15%-20%. The main function is to quickly infiltrate the rainwater from the road surface into the ground, and complete the primary filtration of the road runoff to prevent some large particles from entering the ground.

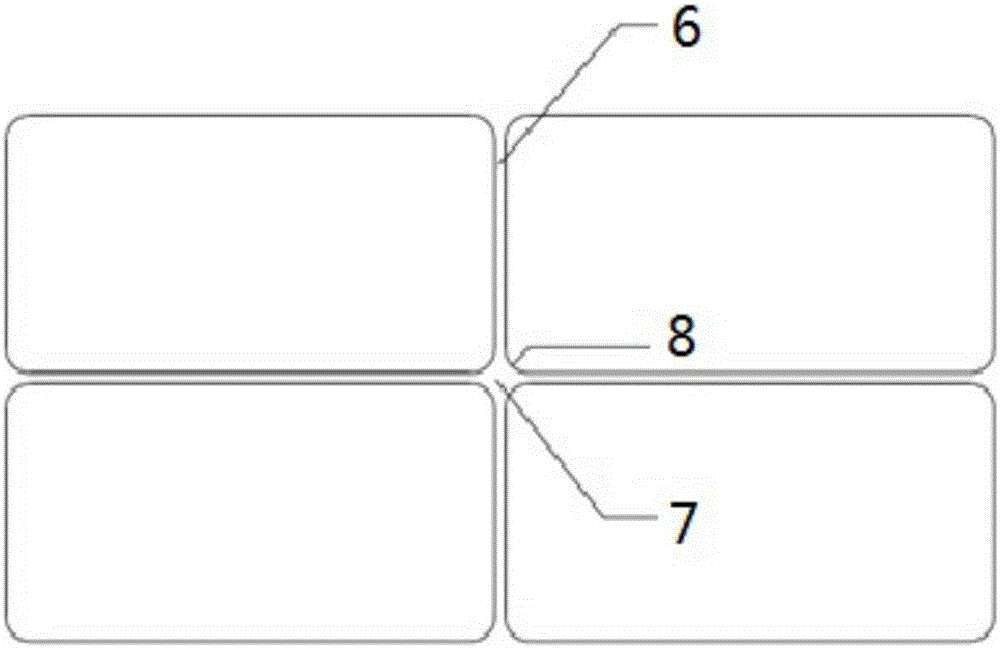

[0114] The permeable brick can be a common type of permeable brick on the market, and the corner of the permeable brick is 4-6mm (or the radius of the inverted arc is 4-6mm). The gaps at the corners of the permeable pavement are microbial channels for microbial addition.

[0115] 2) Leveling layer

[0116] A leveling layer is set under the permeable brick, which is a structural layer for leveling and...

Embodiment 2

[0123] Embodiment 2, microorganism injector

[0124] 1) The types of microorganisms are mainly hydrocarbon oxidizing bacteria, hydrocarbon degrading bacteria and petroleum degrading bacteria. This type of microorganism uses petroleum hydrocarbons as a carbon source for assimilation and degradation, and finally completely mineralizes and transforms them into harmless inorganic substances, thereby reducing oil pollution.

[0125] 2) The added microorganisms are prepared microbial bacterial liquids, which contain the nutrients required by the microorganisms.

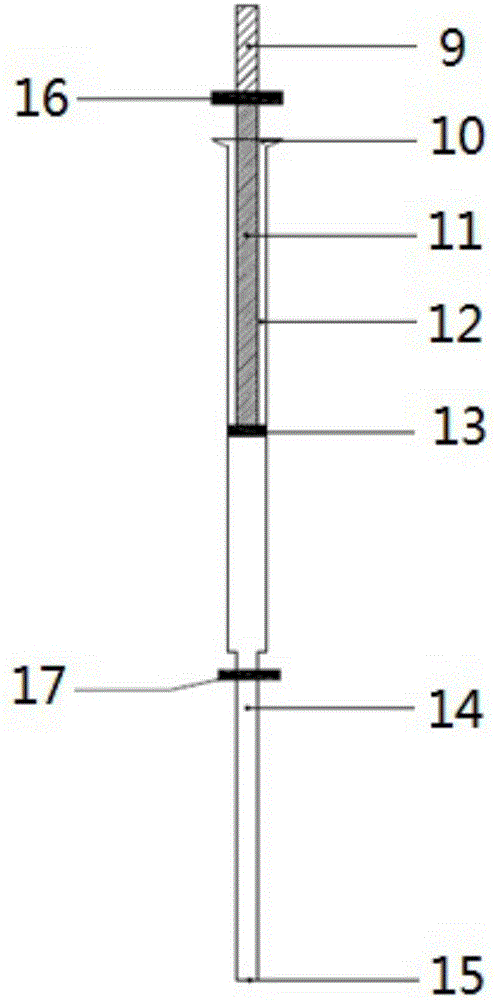

[0126] 3) Microorganisms are added using matching microbial syringes. The main material of the syringe is PVC.

[0127] The microbial syringe includes a handle, a nozzle, a connecting rod, a hollow tube, a piston, an injection tube, an injection port, an upper baffle, and a lower baffle; an injection tube is provided at the front end of the hollow tube, and a connecting rod is provided in the hollow tube , one end of the...

Embodiment 3

[0130] Embodiment 3, permeable pavement method

[0131] 1. Construction of each layer of permeable pavement

[0132] 1) Excavation of the subgrade: according to the design requirements, excavate the roadbed, clear the earthwork, and reach the design elevation; check whether the longitudinal slope, transverse slope and sideline meet the design requirements; repair the subgrade, level and compact it, and the compaction coefficient Up to 95% or more.

[0133] 2) Laying of permeable base: Lay 80-120mm thick natural graded gravel material and sand-free concrete, and level and compact, with a compaction coefficient of more than 95%.

[0134] 3) Laying of permeable geotextile: laying 300g / m 2 Permeable geotextile.

[0135] 4) Laying of the microbial reaction layer: first place the biological ceramsite in the plastic mesh (the plastic mesh diameter is smaller than the ceramsite particle size to avoid the loss of the ceramsite), then immerse it in the prefabricated microbial bacteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com