Epitaxial wafer of light-emitting diode and growth method thereof

A technology of light-emitting diodes and growth methods, applied in the field of epitaxial wafers of light-emitting diodes and their growth, can solve problems such as dislocations that are difficult to eliminate, screw dislocation lattices, defects, etc., to improve internal quantum efficiency and antistatic ability, improve The effect of crystal quality and growth temperature improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

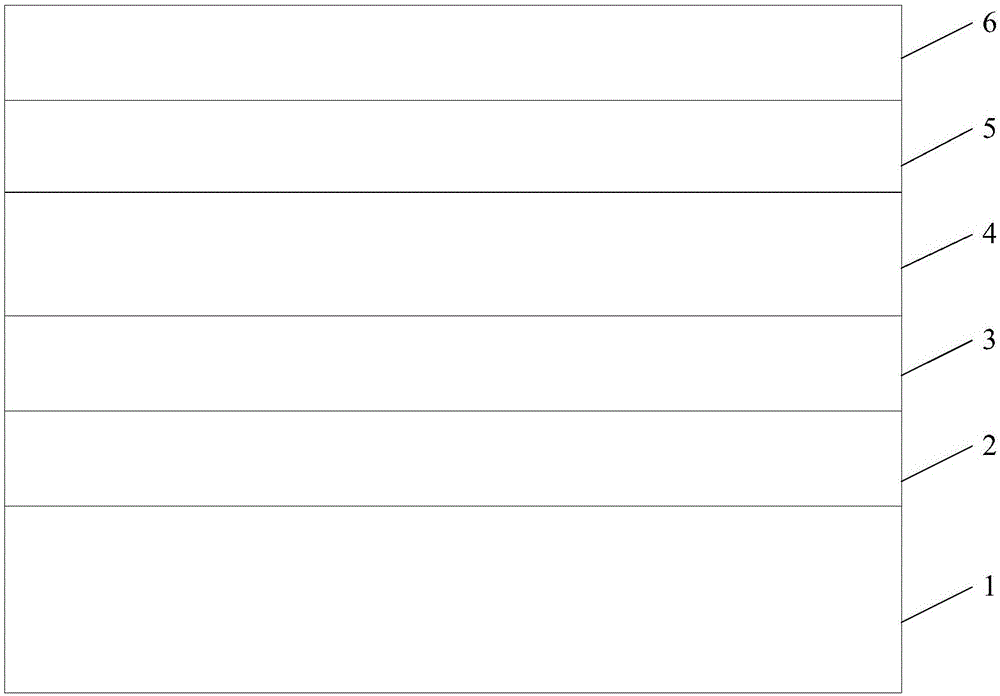

[0028] An embodiment of the present invention provides an epitaxial wafer of a light emitting diode, see figure 1 , the epitaxial wafer includes a substrate 1 , and a buffer layer 2 , an undoped GaN layer 3 , an N-type GaN layer 4 , a light emitting layer 5 , and a P-type GaN layer 6 stacked on the substrate 1 in sequence.

[0029] In this embodiment, the buffer layer is doped with Mg.

[0030] Specifically, the doping concentration of Mg in the buffer layer is smaller than the doping concentration of the P-type dopant in the P-type GaN layer.

[0031] Optionally, the buffer layer may include one of GaN layers, AlGaN layers, InGaN layers, AlInGaN layers, alternately stacked InGaN layers, and AlGaN layers.

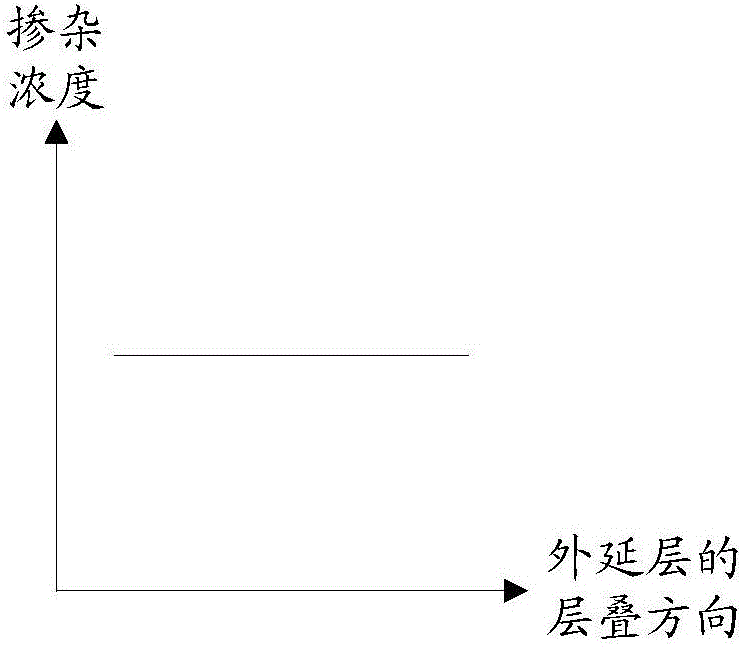

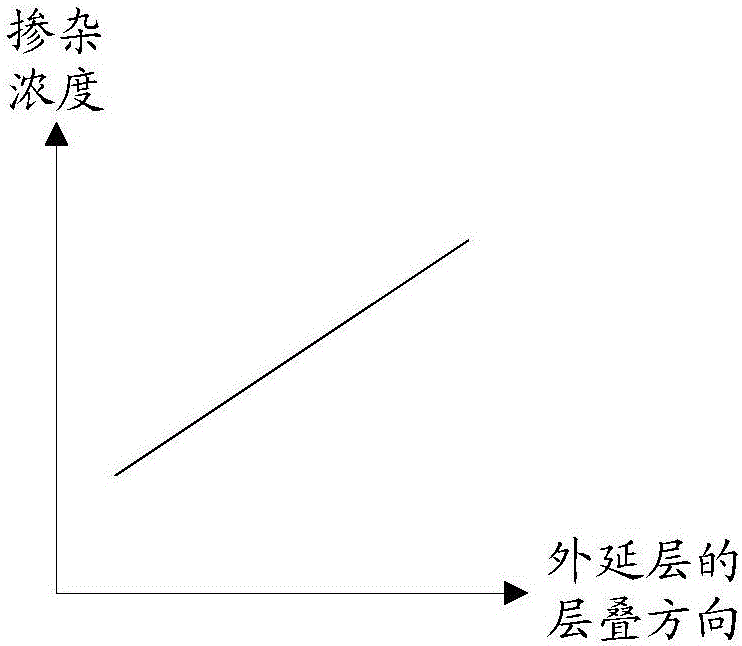

[0032] Optionally, the doping concentration of Mg in the buffer layer can be changed in one of the following ways: remain unchanged (such as Figure 2a shown), gradually increasing along the stacking direction of the epitaxial wafer (such as Figure 2b shown), and gradua...

Embodiment 2

[0045] An embodiment of the present invention provides a method for growing an epitaxial wafer of a light emitting diode, which is suitable for growing the epitaxial wafer provided in Embodiment 1. Realized using high-purity H 2 or N 2 As carrier gas, TMGa, TMAl, TMIn and NH 3 As Ga source, Al source, In source and N source respectively, using SiH 4 and Cp 2 Mg is used as an N-type dopant and a P-type dopant respectively, and metal-organic chemical vapor deposition equipment or other equipment is used to complete the growth of epitaxial wafers.

[0046] Specifically, see Figure 4 , the growth method includes:

[0047] Step 201: growing a buffer layer on a substrate.

[0048] In this embodiment, the buffer layer is doped with Mg.

[0049]Specifically, the doping concentration of Mg in the buffer layer is smaller than the doping concentration of the P-type dopant in the P-type GaN layer.

[0050] Optionally, the buffer layer may include one of GaN layers, AlGaN layers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com