Preparation method for sulfur-doped carbon oxygen reduction electrocatalyst

An electrocatalyst and sulfur doping technology, which is applied to circuits, electrical components, battery electrodes, etc., can solve the problems of difficulty in recycling waste lithium thionyl chloride batteries, cumbersome reaction steps, and high equipment requirements, and achieves good catalytic effect and preparation method. Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of sulfur-doped carbon-oxygen reduction electrocatalyst, the operation steps are as follows:

[0028] (1) Disassemble the waste lithium thionyl chloride battery (ER14250), and collect the sulfur / carbon black mixture in the battery after discharge;

[0029] (2) keeping the sulfur / carbon black mixture obtained in step (1) at a temperature of 800° C. for heat treatment for 30 minutes in nitrogen, and cooling;

[0030] (3) adding 1 g of the obtained sulfur / carbon black mixture after cooling in the step (2) into 100 ml concentration is 1mol / L hydrochloric acid solution and stirred for 6 hours, then filtered, and the filter residue was washed with deionized water until the deionized water flowing out was neutral , dry the filter residue until the water content is less than 5wt%, and collect the obtained sample, which is the sulfur-doped carbon-oxygen reduction electrocatalyst.

Embodiment 2

[0032] A preparation method of sulfur-doped carbon-oxygen reduction electrocatalyst, the operation steps are as follows:

[0033] (1) Disassemble the waste lithium thionyl chloride battery (ER14250), and collect the sulfur / carbon black mixture in the battery after discharge;

[0034] (2) keep the sulfur / carbon black mixture obtained in the step (1) at a temperature of 500° C. for heat treatment for 150 minutes in nitrogen, and cool;

[0035] (3) Gained adding concentration after cooling in step (2) is to stir in 5mol / L10ml sulfuric acid solution for 2 hours, then filter, clean the filter residue with deionized water until the effluent is neutral, and the gained filter residue is dried to moisture less than 5wt%, Collect the sulfur-doped carbon-oxygen reduction electrocatalyst.

Embodiment 3

[0037] A preparation method of sulfur-doped carbon-oxygen reduction electrocatalyst, the operation steps are as follows:

[0038] (1) Disassemble the waste lithium thionyl chloride battery (ER14250), and collect the sulfur / carbon black mixture in the battery after discharge;

[0039] (2) keep the sulfur / carbon black mixture obtained in the step (1) at a temperature of 1100° C. for heat treatment for 10 minutes in hydrogen, and cool;

[0040] (3) Add the nitric acid solution and hydrofluoric acid mixed acid solution (the nitric acid solution of 3mol / L and the 3mol / L hydrofluoric acid solution volume ratio 1:1 mixing) that the concentration obtained after cooling in step (2) is 3mol / L1000ml Stir for 10 hours, then filter, wash the filter residue with deionized water until the effluent is neutral, dry the obtained filter residue until the water content is less than 5wt%, and collect the sulfur-doped carbon-oxygen reduction electrocatalyst.

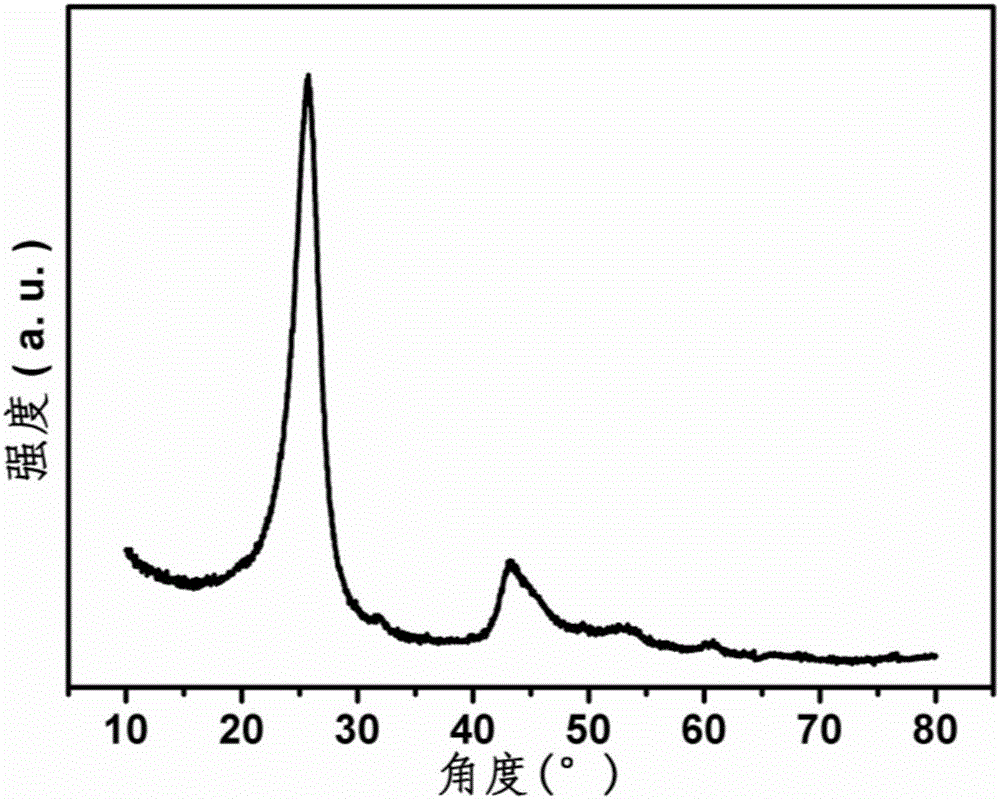

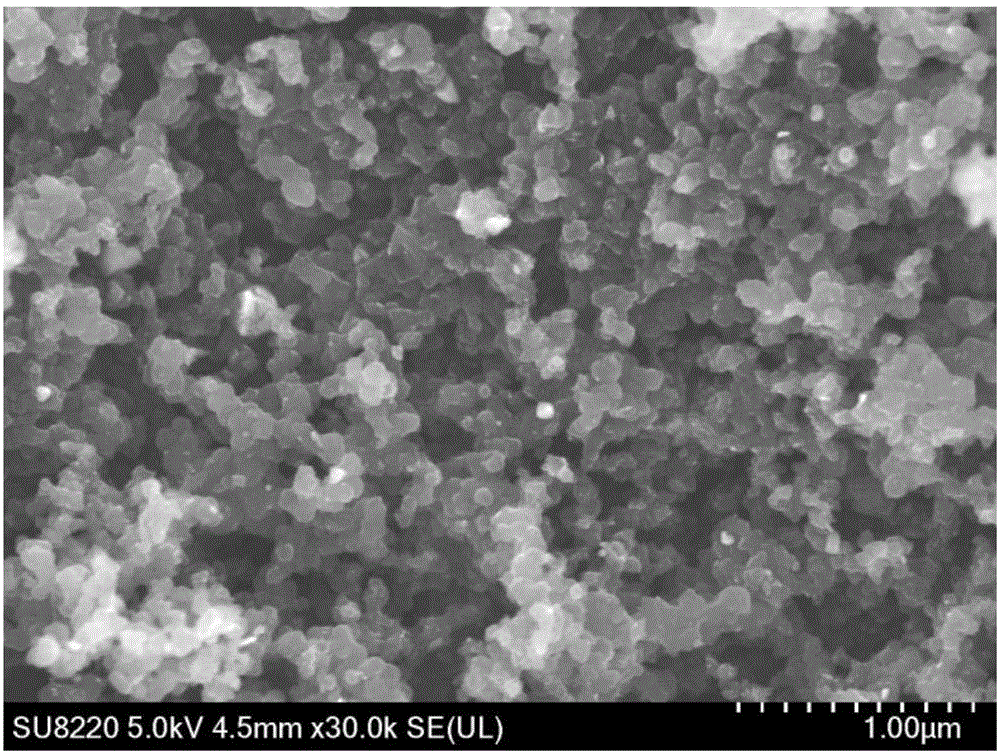

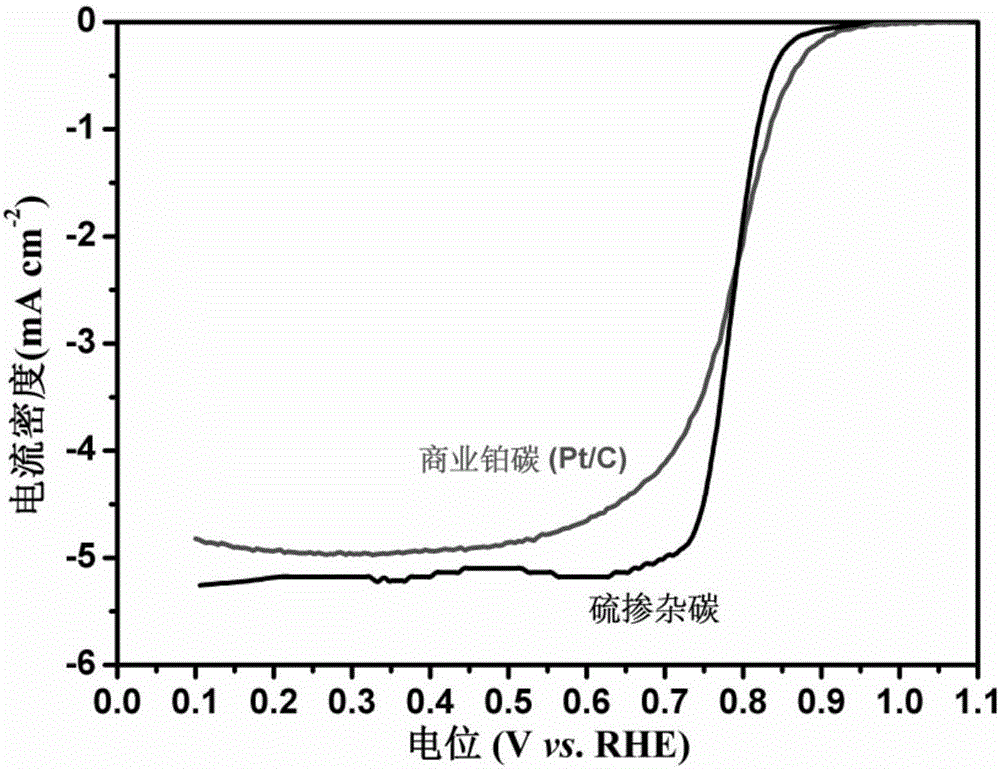

[0041] Carry out X-ray diffraction, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com