Method for purifying tetracycline in sewage by photocatalysis method

A tetracycline and photocatalytic technology, applied in the field of environmental water treatment, can solve the problems of water environmental ecosystem damage, breaking water body balance, low mechanization intensity, etc., and achieve efficient removal, convenient operation, and wide visible light range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

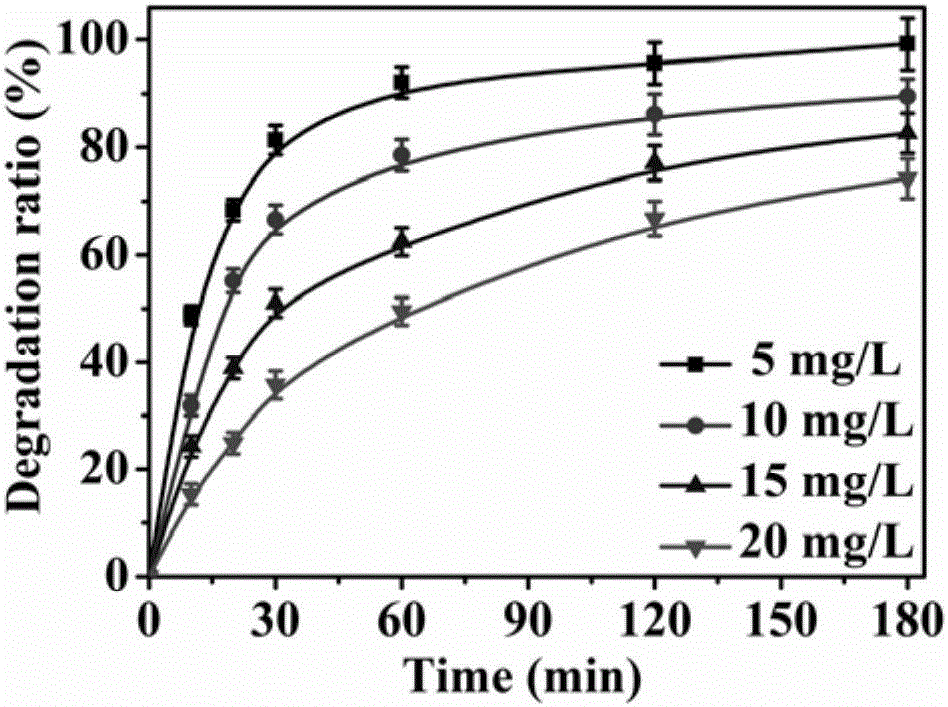

[0033] Measure 100 milliliters of tetracycline-contaminated sewage with a tetracycline concentration of 5 mg / liter and place it in a 150 milliliter glass beaker, add 25 milligrams of (CuAg) 0.15 In 0.3 Zn 1.4 S 2 Quaternary sulfide visible light catalyst. The above mixed system was ultrasonically dispersed for 5 minutes in the dark to completely disperse the photocatalyst in the solution. Before irradiation, the mixed solution was placed on a magnetic stirrer to start stirring (800 rpm), and kept away from light for 20 minutes to achieve the adsorption-desorption equilibrium of tetracycline on the surface of the photocatalyst. Then irradiate with a xenon lamp (500 watts, 300-800 nm) at 800 rpm, and the temperature of the reaction solution is kept at (20±2)° C. by a water bath. Take 1 ml of samples regularly, centrifuge to get the supernatant, and use HPLC to analyze the concentration of tetracycline after sampling. After 3 hours, the removal rate of tetracycline in water ...

Embodiment 2

[0035] Measure 100 milliliters of tetracycline-contaminated sewage with a tetracycline concentration of 10 mg / liter and place it in a 150 milliliter glass beaker, add 25 milligrams of (CuAg) 0.15 In 0.3 Zn 1.4 S 2 Quaternary sulfide visible light catalyst. The above mixed system was ultrasonically dispersed for 5 minutes in the dark to completely disperse the photocatalyst in the solution. Before irradiation, the mixed solution was placed on a magnetic stirrer to start stirring (800 rpm), and kept away from light for 20 minutes to achieve the adsorption-desorption equilibrium of tetracycline on the surface of the photocatalyst. Then irradiate with a xenon lamp (500 watts, 300-800 nm) at 800 rpm, and the temperature of the reaction solution is kept at (20±2)° C. by a water bath. Take 1 ml of samples regularly, centrifuge to get the supernatant, and use HPLC to analyze the concentration of tetracycline after sampling. The method can remove 89.5% of tetracycline in water aft...

Embodiment 3

[0037] Measure 100 milliliters of tetracycline-contaminated sewage with a tetracycline concentration of 15 mg / liter and place it in a 150 milliliter glass beaker, add 25 milligrams of (CuAg) 0.15 In 0.3 Zn 1.4 S 2 Quaternary sulfide visible light catalyst. The above mixed system was ultrasonically dispersed for 5 minutes in the dark to completely disperse the photocatalyst in the solution. Before irradiation, the mixed solution was placed on a magnetic stirrer to start stirring (800 rpm), and kept away from light for 20 minutes to achieve the adsorption-desorption equilibrium of tetracycline on the surface of the photocatalyst. Then irradiate with a xenon lamp (500 watts, 300-800 nm) at 800 rpm, and the temperature of the reaction solution is kept at (20±2)° C. by a water bath. Take 1 ml of samples regularly, centrifuge to get the supernatant, and use HPLC to analyze the concentration of tetracycline after sampling. The method can remove 82.6% of tetracycline in water aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com