Electrochemical reactor and method for electrocatalytically removing chloride ions

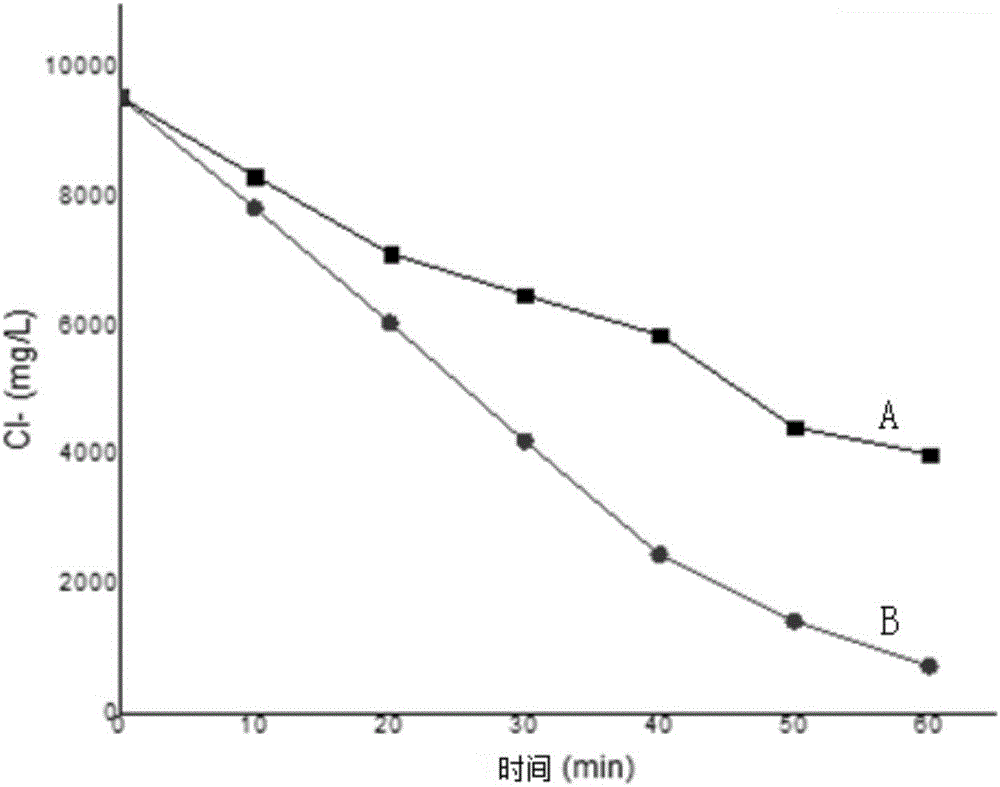

A reactor and electrochemical technology, which is applied in the field of electrochemical reactor and electrocatalytic removal of chloride ions, can solve the problems of restricting large-scale application, long electro-adsorption time, long processing time, etc., and is conducive to large-scale industrial application , high electrolysis efficiency and high degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a method for electrocatalytically removing chloride ions, which is carried out according to the following process:

[0055] The first step, preparation of Ru-Ti-AC catalytic material:

[0056] Soak the activated carbon with a particle size of 30 meshes in 40% phosphoric acid solution for 40 hours, filter the filter cake; wash the filter cake with deionized water until the pH value of the washing solution after washing is 7; wash the filter cake Dry it in a drying oven at 90°C to obtain pretreated activated carbon for subsequent use.

[0057] Take 20g pretreated activated carbon, 40ml butanol, 2gRuCl 3` nH 2 O (as 100% RuCl 3 ), 7.6ml butyl titanate and 2.304g (40ml 0.3M) citric acid were mixed, stirred evenly to obtain a mixed reaction solution, then hydrazine hydrate was added dropwise in the mixed reaction solution, and the pH value of the mixed reaction solution was adjusted to 6.5; then react in a water bath at 92°C for 0.8h to form a vi...

Embodiment 2

[0066] This embodiment provides a method for electrocatalytically removing chloride ions, which is carried out according to the following process:

[0067] The first step, preparation of Ru-Ti-AC catalytic material:

[0068] Soak the activated carbon with a particle size of 5 mesh for 45 hours in a phosphoric acid solution with a mass concentration of 15%, and filter the filter cake; wash the filter cake with deionized water until the pH value of the washing solution after washing is 6.5; wash the filter cake Dry it in a drying oven at 90°C to obtain pretreated activated carbon for subsequent use.

[0069] Take 20g pretreated activated carbon, 40ml butanol, 2gRuCl 3` nH 2 O (as 100% RuCl 3 ), 7.6ml butyl titanate and 2.304g (40ml 0.3M) citric acid were mixed, stirred evenly to obtain a mixed reaction solution, then in the mixed reaction solution, hydrazine hydrate was added dropwise to adjust the pH value of the mixed reaction solution 7; react in a water bath at 95°C for ...

Embodiment 3

[0077] This embodiment provides a method for electrocatalytically removing chloride ions, which is carried out according to the following process:

[0078] The first step, preparation of Ru-Ti-AC catalytic material:

[0079] Soak the activated carbon with a particle size of 100 mesh for 42 hours in a phosphoric acid solution with a mass concentration of 40%, and filter the filter cake; wash the filter cake with deionized water until the pH value of the washing solution after washing is 7; wash the filter cake Dry it in a drying oven at 70°C to obtain pretreated activated carbon for subsequent use.

[0080] Take 20g pretreated activated carbon, 40ml butanol, 2gRuCl 3` nH 2 O (as 100% RuCl 3 ), 7.6ml butyl titanate and 2.304g (40ml 0.3M) citric acid were mixed, stirred evenly to obtain a mixed reaction solution, then in the mixed reaction solution, hydrazine hydrate was added dropwise to adjust the pH value of the mixed reaction solution 7; react in a water bath at 93°C for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com