Molecularly imprinted polymeric microspheres as well as preparation method and application thereof

A technology of molecular imprinting and polymers, which is applied in the preparation of microspheres, microcapsule preparations, alkali metal compounds, etc., can solve the problems of low adsorption efficiency and complex preparation methods of molecularly imprinted polymer microspheres, and achieve multiple adsorption sites, With selectivity and enrichment ability, the effect of strong selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

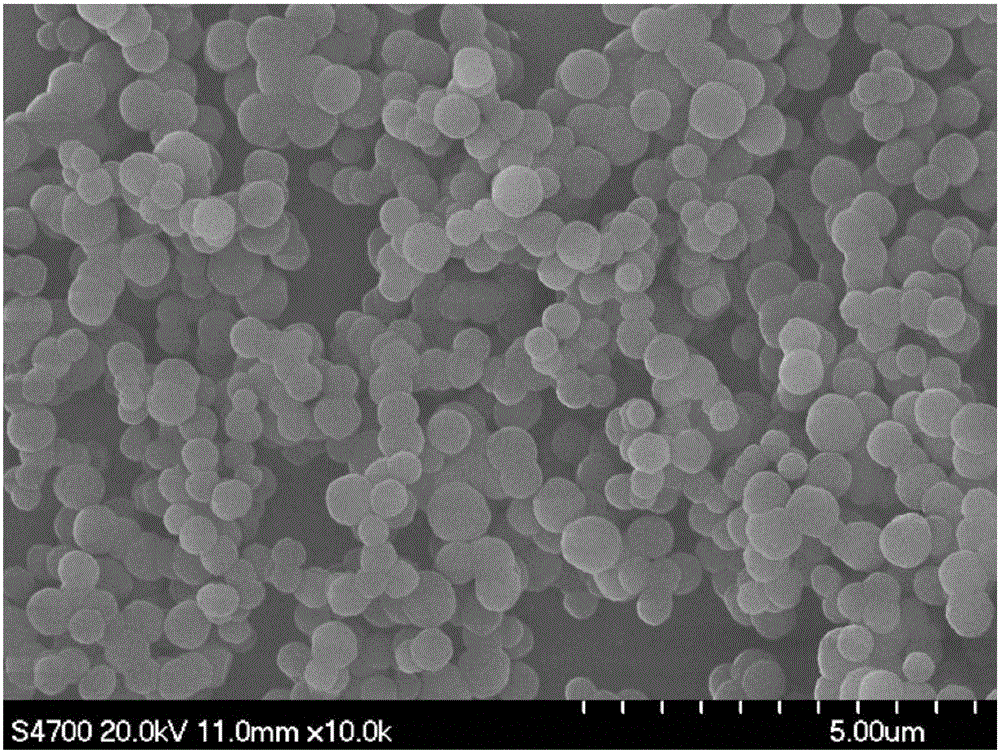

[0049] 3 mmol of NAM and 18 mmol of MAA were weighed and dissolved in a mixed solution of 33 g of toluene and 87 g of acetonitrile, sonicated for 1 h, and allowed to stand for 12 h, so that the template molecule and the functional monomer were fully interacted. Then, 60 mmol of DVB and 0.25 g of AIBN were added, sonicated for 15 min, and nitrogen was passed through for 30 min to remove oxygen. The product obtained after polymerization was put into the eluent of acetic acid / methanol (v / v=1 / 9), and the ultrasonic machine was heated to 60°C, and the template molecule NAM was eluted by ultrasonic. After multiple ultrasonic centrifugation processes, the supernatant of the eluate was detected with a UV-visible spectrophotometer until the UV absorption peak of NAM in the upper eluate disappeared, the template molecules in the MIPs were considered to have been eluted, and then methanol was used. The MIPs were washed three times, the acetic acid was removed, and dried in a vacuum oven ...

Embodiment 2

[0053] 3 mmol of NAM and 21 mmol of MAA were weighed and dissolved in a mixed solution of 48 g of toluene and 98 g of acetonitrile, sonicated for 15 min, and allowed to stand for 14 h to make the template molecule and functional monomer fully interact. Then, 90 mmol of DVB and 0.41 g of AIBN were added, ultrasonicated for 20 min, and nitrogen gas was passed through for 60 min to remove oxygen. The product obtained after polymerization was put into the eluent of acetic acid / methanol (v / v=1 / 10), and the ultrasonic machine was heated to 50°C, and the template molecule NAM was eluted by ultrasonic. After multiple ultrasonic centrifugation processes, the supernatant of the eluate was detected with a UV-visible spectrophotometer until the UV absorption peak of NAM in the upper eluate disappeared, the template molecules in the MIPs were considered to have been eluted, and then methanol was used. The MIPs were washed three times, the acetic acid was removed, and dried in a vacuum oven...

Embodiment 3

[0059] 3 mmol of NAM and 15 mmol of MAA were weighed and dissolved in a mixed solution of 23 g of toluene and 81.7 g of acetonitrile, ultrasonicated for 30 min, and allowed to stand for 12 h, so that the template molecule and the functional monomer were fully interacted. Then, 45 mmol of DVB and 0.16 g of AIBN were added, sonicated for 20 min, and nitrogen was purged for 20 min to remove oxygen. The product obtained after polymerization was put into the eluent of acetic acid / methanol (v / v=1 / 8), and the ultrasonic machine was heated to 40°C, and the template molecule NAM was eluted by ultrasonic. After multiple ultrasonic centrifugation processes, the supernatant of the eluate was detected with a UV-visible spectrophotometer until the UV absorption peak of NAM in the upper eluate disappeared, the template molecules in the MIPs were considered to have been eluted, and then methanol was used. The MIPs were washed three times, the acetic acid was removed, and dried in a vacuum ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com