Method for constructing photocatalytic anti-bacterial and anti-fouling material with ring opening method

A photocatalytic and polymer technology, applied in the direction of antifouling/underwater coatings, polyether coatings, biocide-containing paints, etc., can solve the problem of compatibility, stability, dispersion and storage stability of nano-TiO2 photocatalytic antibacterial materials There are problems such as insufficient lifespan and not very extensive, to achieve the effect of obvious antibacterial effect on the surface and obvious antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Take 1 mmol of Acid Red 87 and completely dissolve it in 5 mL of N,N-dimethylformamide (DMF), then dissolve 1.5 mmol of 3-bromopropylamine hydrobromide in the solution, and wrap it in tin foil. React the system at 80°C for 7 hours, add 20 mL of ether and stir for 18 hours, then add 20 mL of deionized water and stir for 18 hours, and centrifuge to remove unreacted Acid Red 87, 3-bromopropylamine hydrobromide and most of the SolventDMF. After centrifugation, put it into a vacuum drying oven and dry it for 24 hours, and the product is a red powder. This powder is the desired product, denoted as EY-NH2.

example 2

[0029] Get 1mmol of the EY-NH obtained in Example 1 Dissolve in 10mL of DMSO, add 2mmol of polyethylene glycol diglycidyl ether (PEGDGE) and 1mmol of N, tert-butoxycarbonyl-1,2 ethylenediamine , and 1 mmol triethylamine was added, nitrogen gas was bubbled through for 5 min, and the system was reacted at 80° C. for 3 h under magnetic stirring. Then inject 2mLED with a syringe to completely open the ring of unreacted primary amino groups. At this time, the reaction solution was precipitated with ether and washed twice with ether, the supernatant was removed by centrifugation, and the ether was dried to obtain a yellow mucus. Dissolve with a small amount of pure water, and then dialyze with a 3500 dialysis bag for 2 days to remove ED, then take out the liquid in the dialysis bag and freeze-dry to obtain a red powder product, which is the product we need, recorded as EY-PEGDGE-ED-BOC .

[0030] The number average molecular weight (Mn) of the polymer (EY-PEGDGE-ED-BOC) was 14169,...

example 3

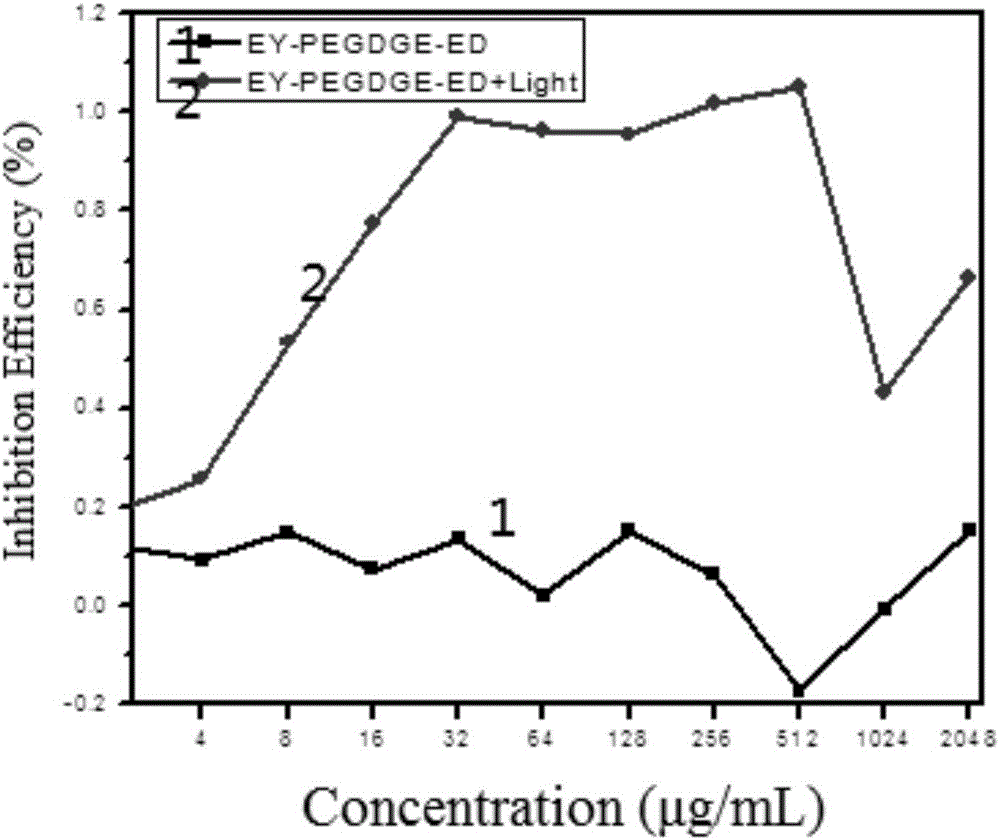

[0032] Dissolve 1 mmol of EY-PEGDGE-ED-BOC obtained in Example 2 in 10 mL of dichloromethane solution, add 2 mL of trifluoroacetic acid, react at room temperature for 12 hours, then remove the dichloromethane solution by rotary evaporation, precipitate with ether, sonicate, and centrifuge , so that the -BOC protecting group of EY-PEGDGE-ED-BOC is removed to obtain a water-soluble photocatalytic antibacterial and antifouling material, which is denoted as EY-PEGDGE-ED.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com