Graphene heat-conduction anticorrosion paint and preparation method thereof

A technology of anti-corrosion coatings and graphene, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of increasing the amount of thermally conductive fillers and reducing the corrosion resistance of coatings, so as to improve thermal conductivity and corrosion resistance The effect of improved performance, uniformity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

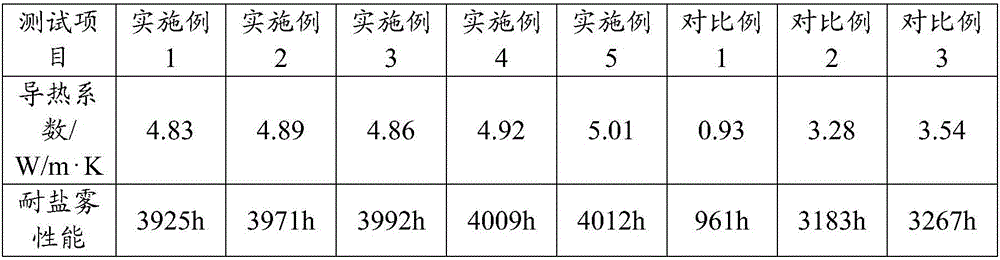

Examples

Embodiment 1

[0047] A kind of graphene heat conduction anticorrosion coating, is made up of the component of following parts by weight: 1 weight part graphene (C / O mol ratio is 7), 25 weight parts epoxy resin E51, 14 weight parts aluminum powder (300 orders) , 0.5 parts by weight of aminoethyl disiloxane, 0.5 parts by weight of polyether modified silicone oil, 5 parts by weight of styrene-butadiene-styrene block copolymer, 10 parts by weight of butanediol glycidyl ether and two A mixed solution of toluene (mass ratio 1:1).

[0048] The preparation method of the above graphene thermally conductive anticorrosion coating comprises the following steps:

[0049] (1) Adopt the improved Hummer method to prepare graphene oxide, utilize the ascorbic acid of environmental protection as reducing agent to obtain reduced graphene oxide, namely graphene;

[0050] (2) each component of above-mentioned ratio according to epoxy resin E51, graphene, aluminum powder, styrene-butadiene-styrene block copolyme...

Embodiment 2

[0055] A kind of graphene heat conduction anticorrosion coating, is made up of the component of following parts by weight: 5 parts by weight graphene (C / O mol ratio is 9.27), 30 parts by weight epoxy resin E44, 5 parts by weight aluminum powder (300 orders) , 10 parts by weight of calcium carbonate (800 mesh), 10 parts by weight of talcum powder (800 mesh), 1 part by weight of KH550, 1 part by weight of polyether modified silicone oil, 7 parts by weight of styrene-isoprene-styrene embedded segment copolymer, a mixed solution of 12 parts by weight of butanediol glycidyl ether and xylene (mass ratio 1:2).

[0056] The preparation method of the above graphene thermally conductive anticorrosion coating comprises the following steps:

[0057] (1) Adopt the improved Hummer method to prepare graphene oxide, utilize the ascorbic acid of environmental protection as reducing agent to obtain reduced graphene oxide, namely graphene;

[0058] (2) each component of above-mentioned proporti...

Embodiment 3

[0062] A kind of graphene heat conduction anticorrosion coating, is made up of the component of following parts by weight: 10 parts by weight graphene (C / O mol ratio is 9.27), 50 parts by weight epoxy resin E44, 10 parts by weight aluminum powder (300 orders) , 10 parts by weight of barium sulfate (1400 mesh), 10 parts by weight of talcum powder (800 mesh), 2 parts by weight of KH550, 2 parts by weight of polyether modified silicone oil, 15 parts by weight of styrene-isoprene-styrene embedded Segment copolymer, a mixed solution of 20 parts by weight of butanediol glycidyl ether and xylene (mass ratio 1:4).

[0063] The preparation method of the above graphene thermally conductive anticorrosion coating comprises the following steps:

[0064] (1) Adopt the improved Hummer method to prepare graphene oxide, utilize the ascorbic acid of environmental protection as reducing agent to obtain reduced graphene oxide, namely graphene;

[0065] (2) each component of above-mentioned ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com