UV adhesiveness control technique during in-situ shaping micro-lens manufacturing process

An in-situ forming and manufacturing process technology, applied in the fields of lenses, optics, instruments, etc., can solve problems such as high risk, complicated process, and inability to change, and achieve the effects of saving manufacturing costs, simplifying manufacturing processes, and simplifying manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

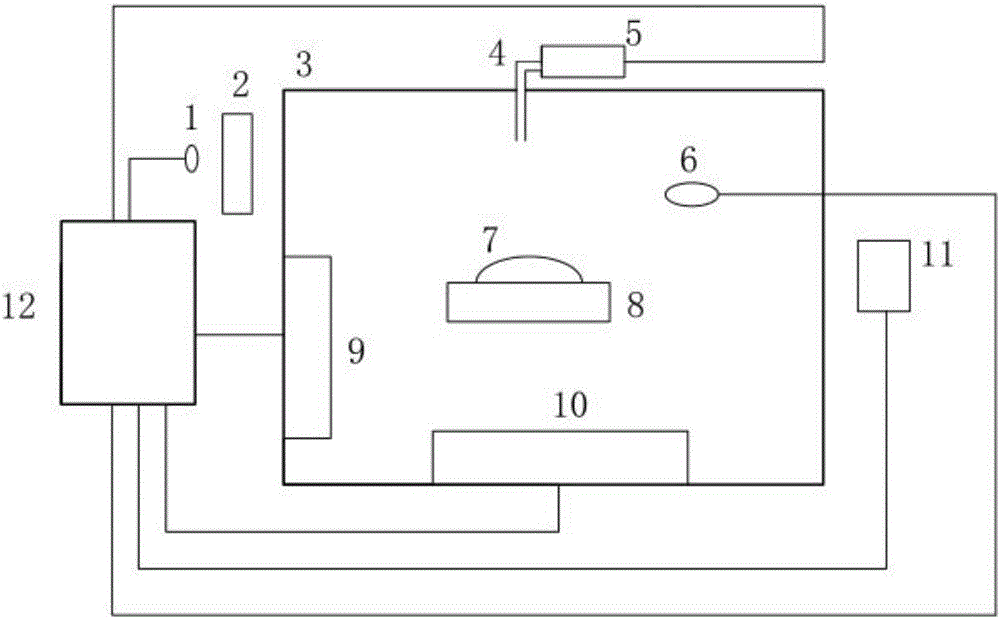

[0029] combine figure 2 To illustrate a specific embodiment of the present invention, the background light source 1 adopts a four-pin ceiling-mounted H-shaped lamp tube, the material of the heat insulation material chamber 3 adopts JGS2 ultraviolet optical quartz glass, the precision syringe pump 5 adopts a V6 precision syringe pump, and the ultraviolet light source 6 Using a laser light source, the energy density is limited to 5J / cm 2 within. Through the control circuit of the upper computer 12, the positive current is applied to the semiconductor refrigeration chip a9 and the semiconductor refrigeration chip b10, so that the semiconductor refrigeration chip starts to cool, and when the temperature in the cavity is close to 5°C, the ultraviolet optical glue in the precision syringe pump 5 is released through the glue droplet The catheter 4 is released onto the target substrate 8 with a volume of about 10 μl. At this time, the change in the shape of the glue droplet is detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com