Rodlike manganese dioxide/polyaniline composite material as well as preparation method and application of rodlike manganese dioxide

A manganese dioxide and composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of prone to volume expansion and poor electrical conductivity, and achieve the effects of increasing utilization, improving electrical conductivity, and good electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

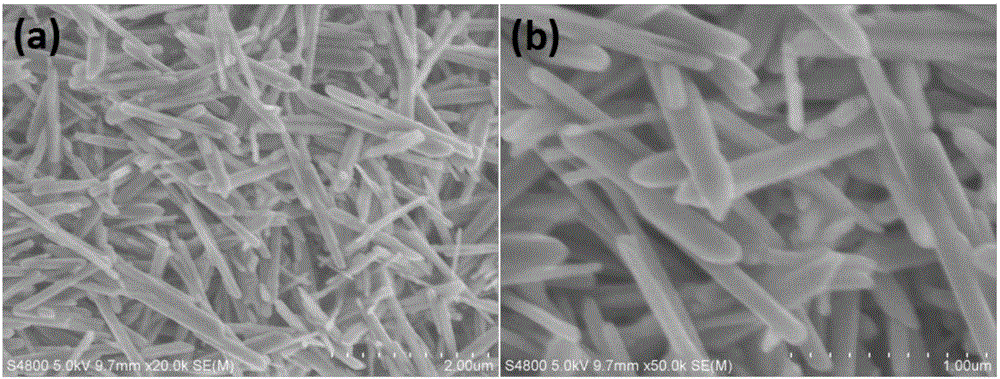

[0047] A kind of rod-shaped manganese dioxide / polyaniline composite material, its preparation method comprises the steps:

[0048] 1) Add 0.004mol (NH 4 ) 2 S 2 o 8 and 0.004mol MnSO 4 ·H 2 O was dissolved in 40mL deionized water respectively, and stirred on a magnetic stirrer for 15min to obtain ammonium persulfate solution and manganese sulfate solution, and the two were mixed uniformly to obtain mixed solution I;

[0049] 2) Add 0.4 g of cationic surfactant CTAB to the obtained mixed solution I, and stir for 15 minutes to obtain a uniform mixed solution II;

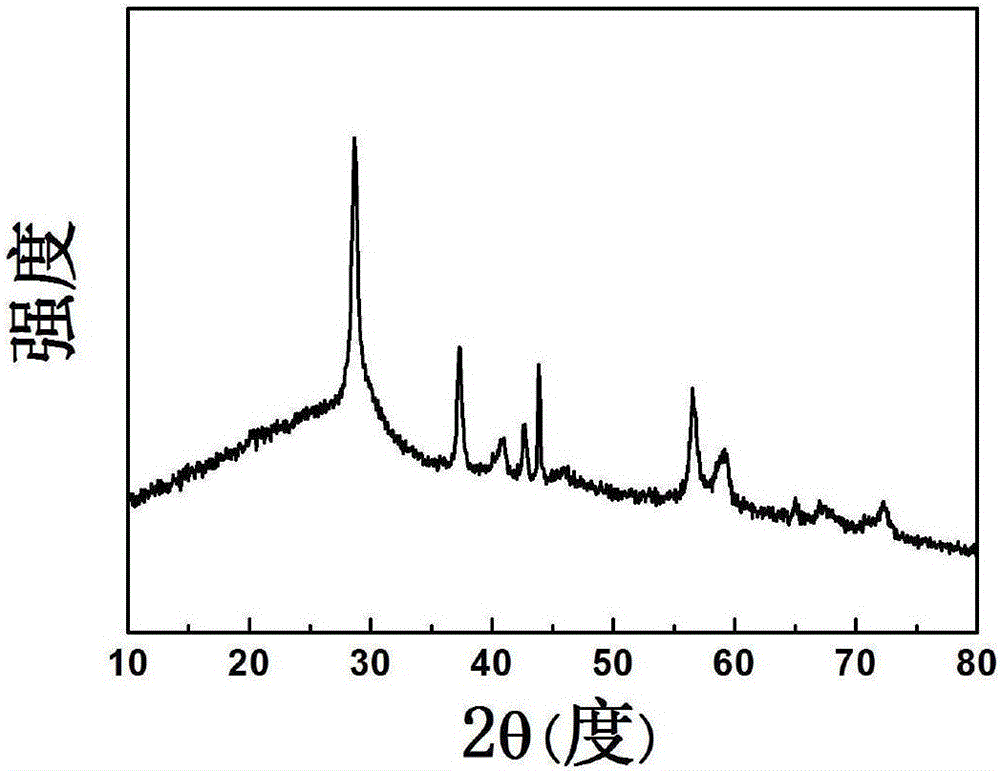

[0050] 3) Transfer the obtained mixed liquid II to a 100mL hydrothermal synthesis reaction kettle, place the hydrothermal synthesis reaction kettle in a heater, heat it to 140°C under an air atmosphere and keep it warm for 12 hours, and take out the obtained solution after the heat preservation reaction Placed at room temperature and naturally cooled to room temperature, a black flocculent precipitate (MnO 2 ); ...

Embodiment 2

[0059] A kind of rod-shaped manganese dioxide / polyaniline composite material, its preparation method comprises the steps:

[0060] 1) Add 0.0045mol (NH 4 ) 2 S 2 o 8 and 0.005mol MnSO 4 ·H 2 O was dissolved in 50mL deionized water respectively, and stirred on a magnetic stirrer for 15min to obtain ammonium persulfate solution and manganese sulfate solution, and the two were mixed uniformly (continue to stir for 25min) to obtain mixed solution I;

[0061] 2) Add 0.5 g of cationic surfactant CTAB to the obtained mixed solution I, and stir for 20 minutes to obtain a uniform mixed solution II;

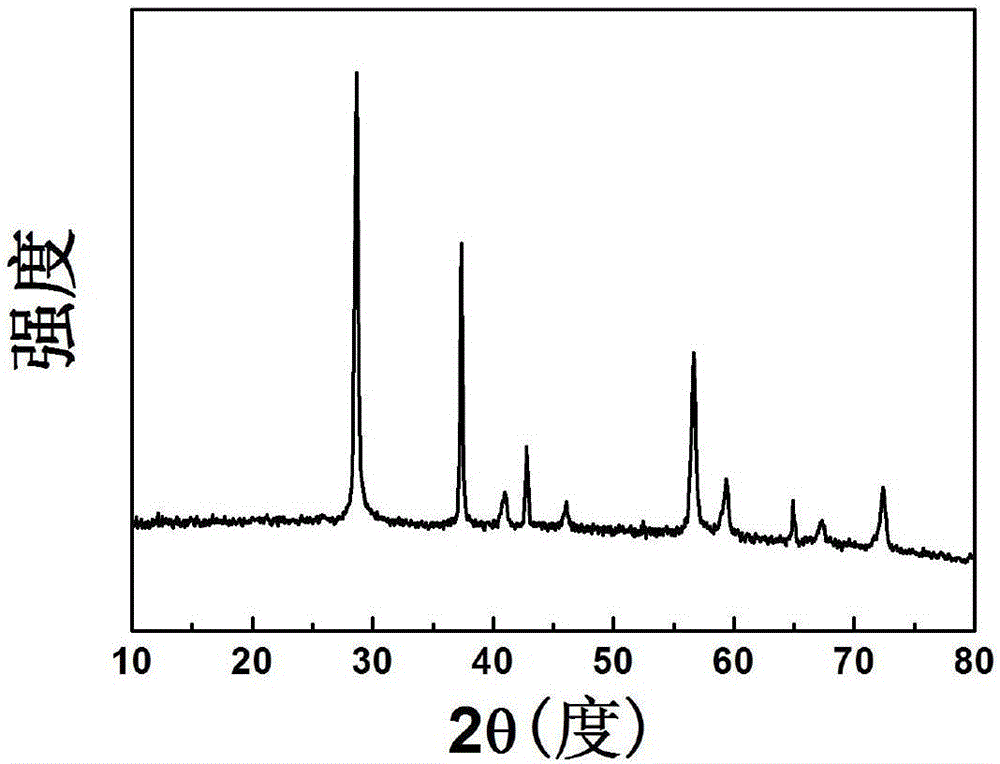

[0062] 3) Transfer the obtained mixed solution II to a 150mL hydrothermal synthesis reaction kettle, place the hydrothermal synthesis reaction kettle in a heater, heat it to 140°C under an air atmosphere and keep it warm for 14 hours, and take out the obtained solution after the heat preservation reaction Placed at room temperature and naturally cooled to room temperature, a black fl...

Embodiment 3

[0070] A kind of rod-shaped manganese dioxide / polyaniline composite material, its preparation method comprises the steps:

[0071] 1) Add 0.009mol (NH 4 ) 2 S 2 o 8 and 0.008molMnCl 2 ·H 2 O was dissolved in 100mL deionized water respectively, and stirred on a magnetic stirrer for 15 minutes to obtain ammonium persulfate solution and manganese chloride solution, and the two were mixed uniformly (continue to stir for 20 minutes) to obtain mixed solution I;

[0072] 2) Add 2 g of cationic surfactant CTAB to the obtained mixed solution I, and stir for 25 minutes to obtain a uniform mixed solution II;

[0073] 3) Transfer the obtained mixed solution II to a 250mL hydrothermal synthesis reaction kettle, place the hydrothermal synthesis reaction kettle in a heater, heat it to 140°C under an air atmosphere and keep it warm for 15 hours. After the heat preservation reaction, take out the obtained solution Placed at room temperature and naturally cooled to room temperature, a bla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com