Fungicidal composition containing oxine-copper

A composition, the technology of copper quinoline, applied in the directions of fungicides, biocides, biocides, etc., can solve the problems of resistance generation, shortened duration of validity, unfavorable environmental sustainable development, etc., to improve the prevention effect, research and development Short cycle, suitable for promotion and application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

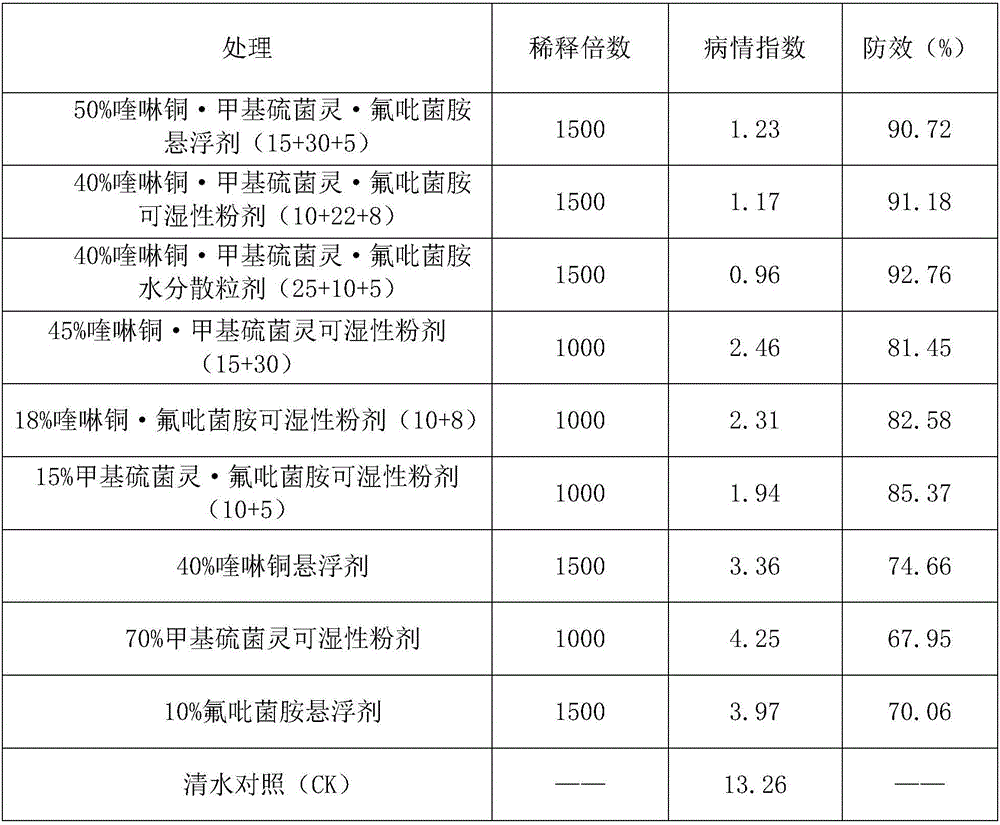

Embodiment 1

[0039] Weigh 15% copper quinolate, 30% thiophanate-methyl, 5% fluopyram, 3% emulsifier Span-60# (common name: sorbitan monostearate), 5% diffusing agent NNO (alkyl naphthalene sulfonate), 2% wetting agent TERSPERSE 2500 (produced by Huntsman, USA), 1% xanthan gum, 5% ethylene glycol, 0.5% silicone defoamer (trade name: s -29 produced by Nanjing Sixin Applied Chemicals Co., Ltd.), and the balance is deionized water. The above-mentioned raw materials are processed through the processes of mixing, pre-crushing, crushing with a sand mill, mixing and blending, and packaging. Different parameter equipment can be selected according to the actual production for the pre-crushing and mixing process. The sand mill pulverization process of the suspending agent in this embodiment uses four sand mills, multi-stage series, using fine sand and coarse sand, the first sander is fully loaded with coarse sand, and the second sander is filled with 2 / 3 coarse sand. Sand and 1 / 3 fine sand, the thi...

Embodiment 2

[0041] Weigh 5% copper quinolate, 24% thiophanate-methyl, 6% fluopyram, 2% TERSPERSE 4894 (produced by Huntsman, USA), 4% agricultural milk 1601# (common name: triphenylethyl Phenol polyoxypropylene polyoxyethylene block polymer), 2% diffusion agent NNO, 1% magnesium aluminum silicate, 5% ethylene glycol, 0.5% formaldehyde, 0.5% silicone defoamer (trade name: s-29 Nanjing Sixin Applied Chemicals Co., Ltd.) and deionized water were added to 100% by weight. The above-mentioned raw materials are processed through the processes of mixing, pre-crushing, crushing with a sand mill, mixing and blending, and packaging. Different parameter equipment can be selected according to the actual production for the pre-crushing and mixing process. The sand mill pulverization process of the suspending agent in this embodiment uses four sand mills, multi-stage series, using fine sand and coarse sand, the first sander is fully loaded with coarse sand, and the second sander is filled with 2 / 3 coar...

Embodiment 3

[0043] Take by weighing 5% copper quinolate, 25% thiophanate-methyl, 8% fluopyram, 2% TERSPERSE 2700 (polycarboxylate, produced by Huntsman, U.S.), 4% dispersant Ufoxane 3A, 1% Pull apart powder BX (sodium dibutylnaphthalene sulfonate), 1% sodium lauryl sulfate (K-12), 2% polyvinylpyrrolidone, 1% white carbon black, and kaolin are added to 100% by weight. The above-mentioned raw materials are prepared through the conventional method for preparing water-dispersible granules, ie, mixing, ultrafine airflow pulverization, mixing, and granulating steps to prepare 38% copper quinolate · thiophanate-methyl · fluopicolide dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com