Manufacturing method for high polymer material three-dimensional product

A technology of polymer materials and manufacturing methods, applied in processing and manufacturing, manufacturing tools, additive manufacturing, etc., can solve the problems of complex temperature control technology in the forming space, poor bonding strength between layers of finished products, and limited range of material selection. Achieve the effects of avoiding thermal deformation, relaxing requirements, and eliminating the need for gas supply devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

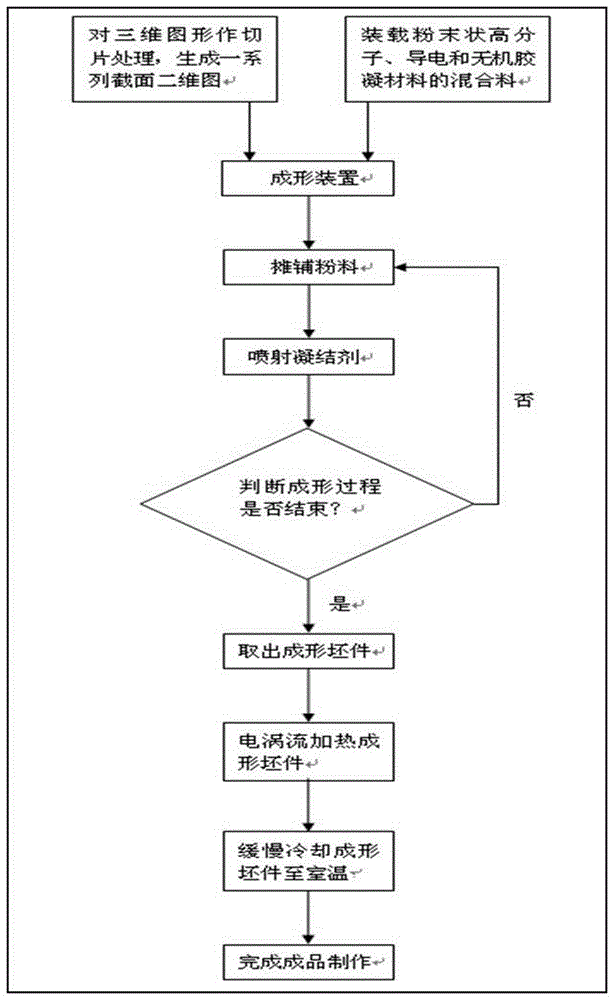

[0048] Please refer to the attached figure 1 , the technical solution is divided into the following steps:

[0049] 1. Discrete the three-dimensional design graphics of the product to be processed into a series of two-dimensional horizontal cross-sectional graphics, and input them into the forming device control computer;

[0050] 2. Load the uniformly mixed powdered EVA hot melt adhesive (polymer material), graphite (conductive material), gypsum (inorganic cementitious material) and other raw materials into the forming device. The ratio of the three is: 5.5:1.5:3 ;

[0051] 3. The powder spreading mechanism in the forming device spreads the powdery raw material into a uniform thin layer with a thickness of about 0.1mm;

[0052] 4. The nozzle or nozzle group array in the forming device sprays the water-based coagulant on the specific area corresponding to the solid part of the cross-section of the product on the above-mentioned thin layer of powder, and the gelling material ...

Embodiment 2

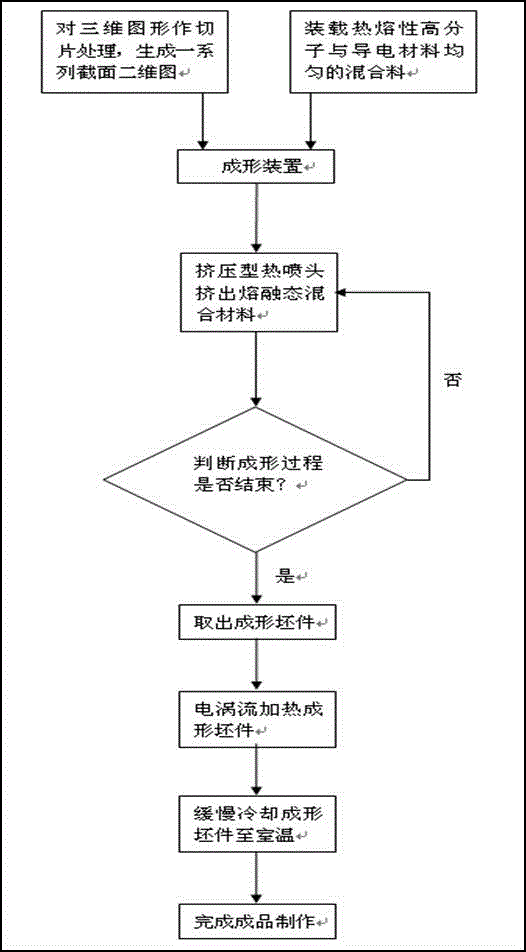

[0059] Please refer to the attached figure 2 , the technical solution is divided into the following steps:

[0060] 1. Discrete the three-dimensional design graphics of the product to be processed into a series of two-dimensional horizontal cross-sectional graphics, and input them into the forming device control computer;

[0061] 2. The filamentous or granular nylon 12 (polymer material) and aluminum powder (conductive material) mixed material that has been uniformly mixed and made is loaded into the forming device, and the ratio of the two is: 7:3;

[0062] 3. Extrude the mixed material of molten nylon 12 and aluminum powder onto the forming plane with an extrusion-type thermal nozzle, and cool to form a thin layer of a corresponding cross-section at a certain height of the blank to be produced;

[0063] 4. The previous step will be repeated until the blank forming process of the product is completed;

[0064] 5. Take out the blank to be finished from the forming device; ...

Embodiment 3

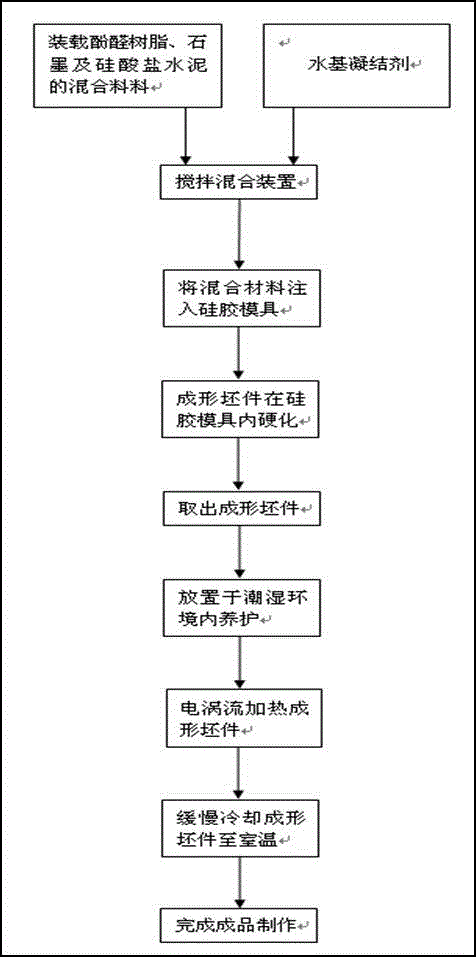

[0069] Please refer to the attached image 3 , the technical solution is divided into the following steps:

[0070] 1. Evenly mix the mixed material consisting of powdered phenolic resin (polymer material), graphite (conductive material), Portland cement (inorganic cementitious material) containing about 10% urotropine, and the ratio of the three is: 5.5:1.5:3;

[0071] 2. The above-mentioned mixture is evenly stirred with an appropriate amount of water-based coagulant, and then poured into a silicone mold of a corresponding shape;

[0072] 3. The slurry is hardened in the silicone mold to form the blank of the three-dimensional product;

[0073] 4. Take out the product blank and place it in a humid environment for several days;

[0074] 5. Put the cured blank into the induction furnace. Under the action of the alternating electromagnetic field, the graphite particles in the blank generate eddy current and generate heat, which makes the blank rapidly rise to the melting poi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com