Three-dimensional graphene foam as well as preparation method and application thereof

A technology of graphene foam and graphene powder, which is applied in graphene, chemical instruments and methods, and other chemical processes, and can solve problems such as time-consuming, easy-to-collapse skeletal structures, etching or pyrolysis processes, and weak physical interactions , to achieve the effect of simple experimental equipment, shortening the preparation cycle, and facilitating large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The graphite oxide prepared by the chemical oxidation method was placed in an ordinary oven for thermal exfoliation and reduction, the thermal exfoliation temperature was 200° C., and the exfoliation time was 5 min. Finally, black fluffy graphene powder is obtained.

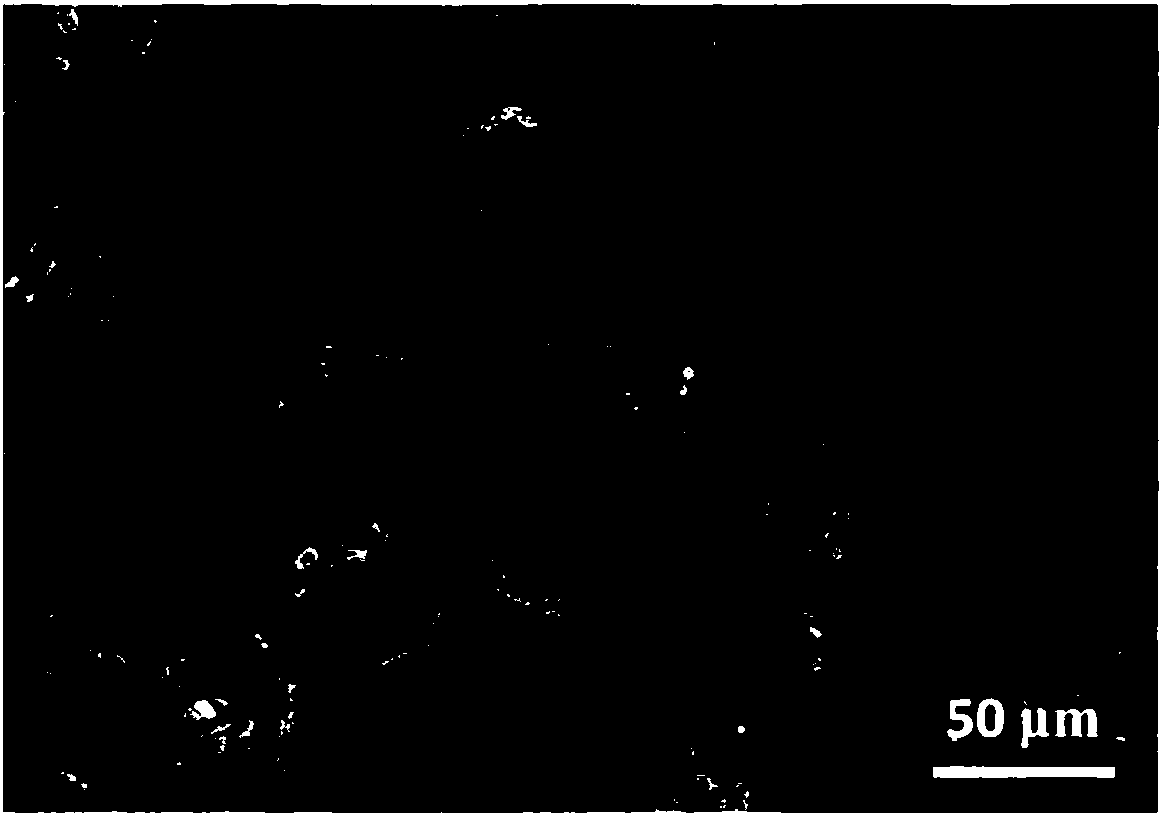

[0038] (2) 0.66g of this graphene powder is packed into a size of φ under the pressure of 54kPa 外 5cm×φ 内 Put it in a graphite crucible of 4cm×5cm, and place it in a high-temperature furnace at 1500°C for 1 hour in a high-purity nitrogen atmosphere to obtain a density of 19mg / cm 3 、BET specific surface area is 338m 2 / g of three-dimensional graphene foam. The appearance of the obtained three-dimensional graphene foam is as follows figure 1 As shown, the scanning electron microscope morphology is shown in figure 2 As shown, the obtained three-dimensional graphene foam not only has good compressive properties and mechanical strength, but also has a continuous worm-like skeleton (graphene aggregates...

Embodiment 2

[0045] Compared with Example 1, the difference is only that in step (2), the graphene powder is placed in a high-temperature furnace and processed in a high-purity nitrogen atmosphere at 1000°C for 1h, and the structure of the three-dimensional graphene foam obtained is similar to that of Example 1, but Density drops to 11mg / cm 3 , BET specific surface area increased to 508m 2 / g.

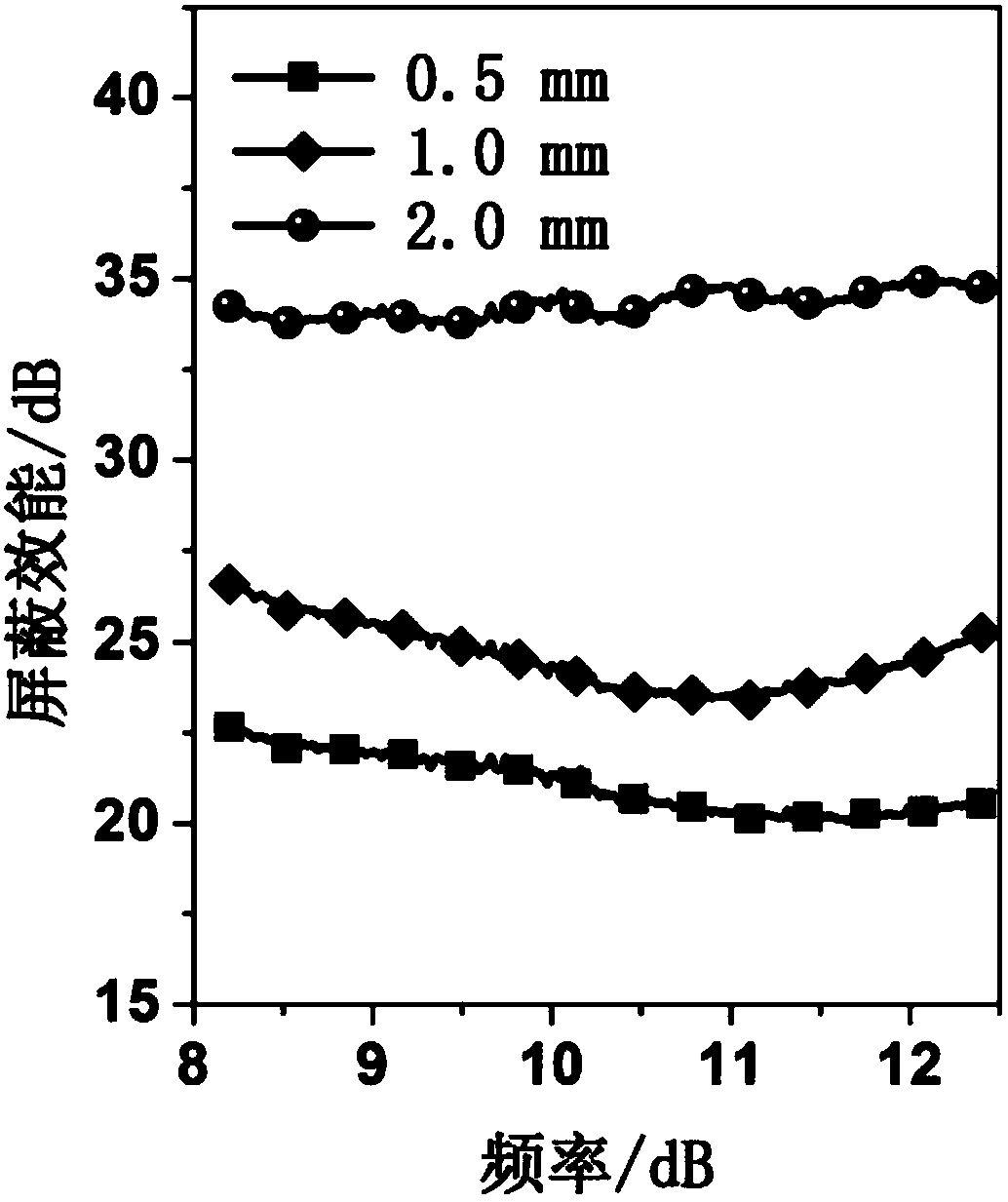

[0046] The three-dimensional graphene foam is encapsulated with epoxy resin to obtain a graphene foam composite material, the quality of the three-dimensional graphene foam is 0.8% of the graphene foam composite material, and then the sample is cut to a thickness of 2.0mm.

Embodiment 3

[0052] Compared with Example 1, the only difference is that in step (2), the graphene powder is placed in a high-temperature furnace and processed in a high-purity nitrogen atmosphere at 2200 ° C for 1 h, and the structure of the three-dimensional graphene foam obtained is similar to that of Example 1, But the density increased to 34mg / cm 3 , BET specific surface area reduced to 108m 2 / g.

[0053] The three-dimensional graphene foam is encapsulated with epoxy resin to obtain a graphene foam composite material, the quality of the three-dimensional graphene foam is 3.3% of the graphene foam composite material, and then the sample is cut to a thickness of 2.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com