Thick-type steel structure fireproof coating and preparation method thereof

A fire-resistant coating and steel structure technology, applied in fire prevention, building components, etc., can solve the problems of increasing steel structure load, low thermal conductivity of coating, heat consumption, etc., to improve heat insulation capacity, reduce thermal conductivity, and improve fire resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

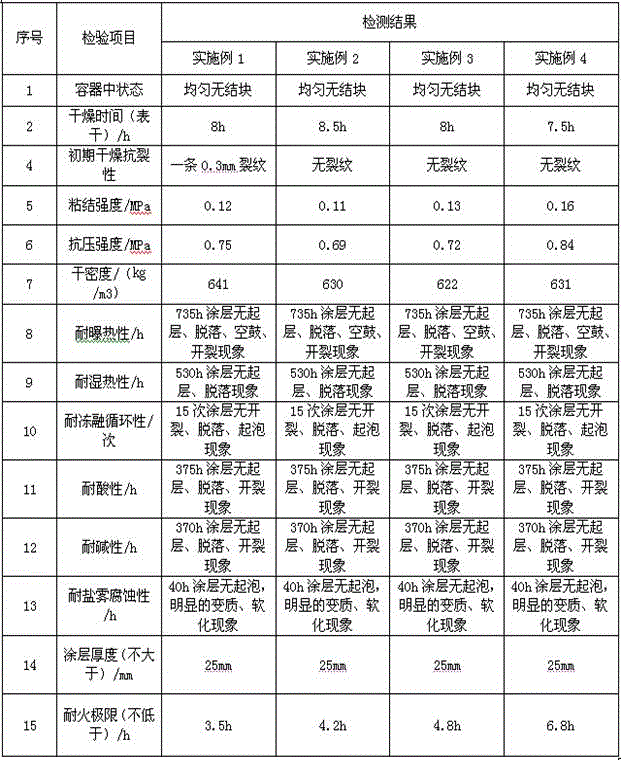

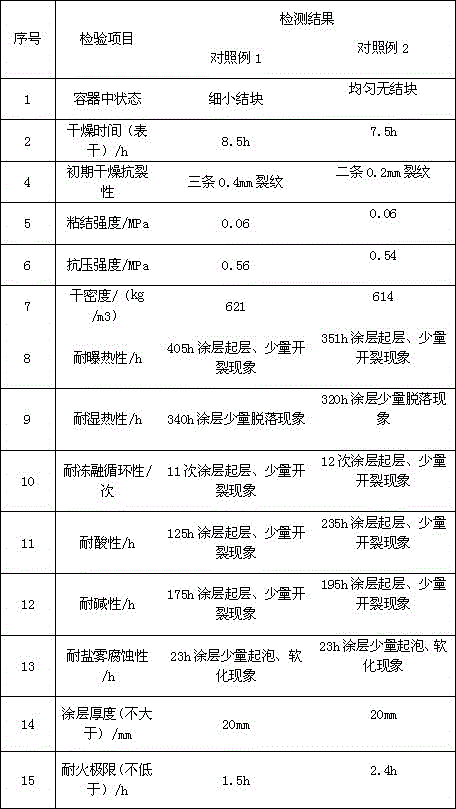

Examples

Embodiment 1

[0058] S0: A thick steel structure fireproof coating is composed of the following composition by weight percentage: Portland cement 30%, fly ash 8%, refractory clay 11%, calcium carbonate 20%, hydrophobic silicon dioxide gas condensation Glue 5%, expanded perlite 23%, air-entraining agent sodium lauryl sulfate 0.03%, water-retaining agent hydroxypropyl methylcellulose 0.4%, flame retardant aluminum hydroxide 1%, German BYK-410 contact Variable agent 0.07%, aluminum silicate fiber 1.5%.

[0059] The particle in the hydrophobic silica airgel is a spherical particle whose surface is replaced by a silyl hydrophobic group to a hydroxyl group, with a diameter of 1-100nm, and the density of the hydrophobic silica airgel is 40kg / m³, Expanded perlite is a lightweight filler with open pores and internal pores, with a bulk density of 55 kg / m³ and a particle size of less than 5mm; the fibers are aluminum silicate fibers with a diameter of less than 5mm and a length of less than 15mm.

[...

Embodiment 2

[0067] S0: A thick steel structure fireproof coating is composed of the following composition by weight percentage: Portland cement 30%, fly ash 8%, refractory clay 11%, calcium carbonate 15%, hydrophobic silicon dioxide gas condensation Glue 10%, expanded perlite 23%, air-entraining agent sodium lauryl sulfate 0.03%, water-retaining agent hydroxypropyl methylcellulose 0.4%, flame retardant aluminum hydroxide 1%, German BYK-410 contact Variable agent 0.07%, aluminum silicate fiber 1.5%.

[0068] The particle in the hydrophobic silica airgel is a spherical particle whose surface is replaced by a silyl hydrophobic group to a hydroxyl group, with a diameter of 1-100nm, and the density of the hydrophobic silica airgel is 40kg / m³, Expanded perlite is a lightweight filler with open pores and internal pores, with a bulk density of 55 kg / m³ and a particle size of less than 5mm; the fibers are aluminum silicate fibers with a diameter of less than 5mm and a length of less than 15mm.

...

Embodiment 3

[0076] S0: A thick steel structure fireproof coating is composed of the following composition by weight percentage: Portland cement 30%, fly ash 8%, refractory clay 11%, calcium carbonate 10%, hydrophobic silicon dioxide gas condensation Glue 15%, expanded perlite 23%, air-entraining agent sodium lauryl sulfate 0.03%, water-retaining agent hydroxypropyl methylcellulose 0.4%, flame retardant aluminum hydroxide 1%, German BYK-410 contact Variable agent 0.07%, aluminum silicate fiber 1.5%.

[0077] The particle in the hydrophobic silica airgel is a spherical particle whose surface is replaced by a silyl hydrophobic group to a hydroxyl group, with a diameter of 1-100nm, and the density of the hydrophobic silica airgel is 40kg / m³, Expanded perlite is a lightweight filler with open pores and internal pores, with a bulk density of 55 kg / m³ and a particle size of less than 5mm; the fibers are aluminum silicate fibers with a diameter of less than 5mm and a length of less than 15mm.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com