Tuble vegetable function fertilizer

A technology for functional fertilizers and vegetables, applied in the directions of potassium fertilizer, nitrogen fertilizer, magnesium fertilizer, etc., can solve the problems of reducing the commerciality and yield of potatoes, affecting the rate of potato setting and large potato, and hindering the expansion of potatoes, so as to maintain healthy growth and prevent The effect of yam deficiency and root vitality enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

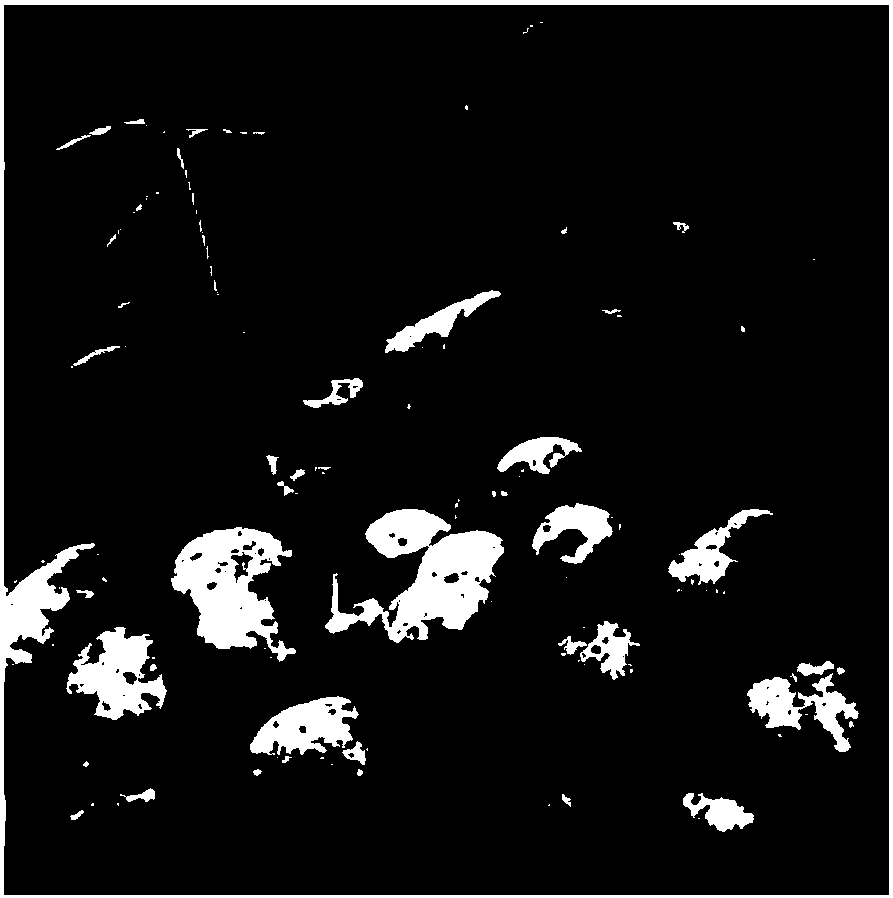

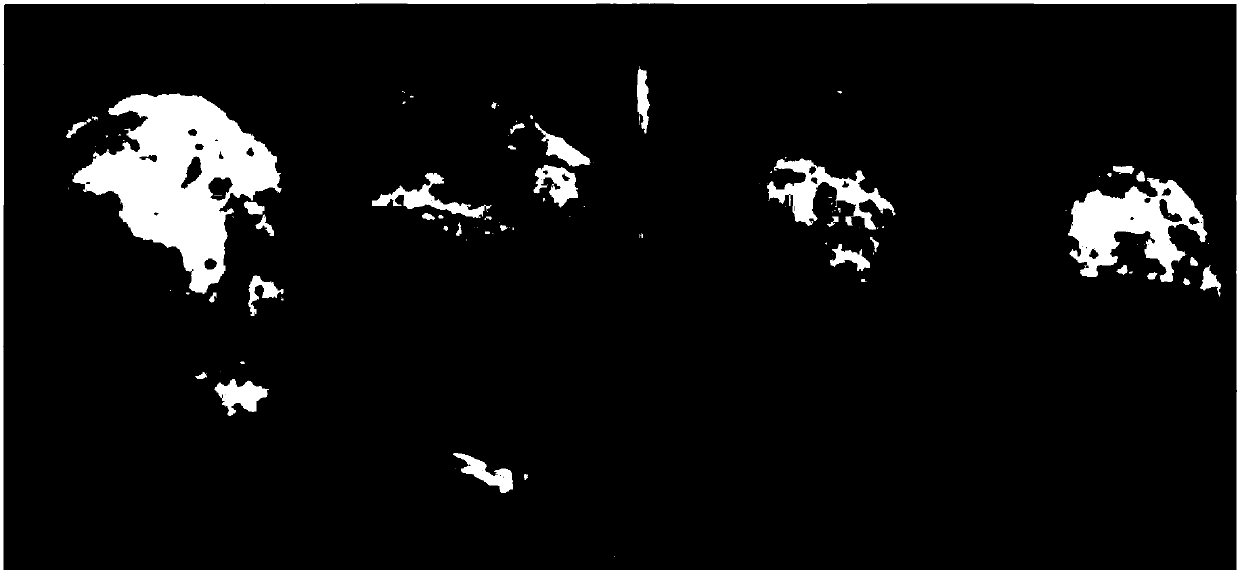

Image

Examples

preparation example Construction

[0043] The preparation method of the above-mentioned yam vegetable functional fertilizer comprises the following steps:

[0044] Adjust the pH of the fermentation waste liquid at 5.0-7.0, heat it to 55-100°C, and then add trace elements for complexation reaction for 1-2 hours to prepare organic carbon;

[0045] Put urea, ammonium sulfate, monoammonium phosphate, potassium sulfate, superphosphate, borax, magnesium sulfate, synergists and other additives in a granulator by weight for conventional granulation production to form fertilizer granules;

[0046] Coat the outer layer of the above-mentioned fertilizer granules with organic carbon and potassium fulvic acid, and finally add the mixed bacterial agent.

[0047] In the functional fertilizer prepared by the above preparation method, the organic carbon is formed by the complexation of fermentation waste liquid and trace elements, which can ensure the content of active ingredients in the fertilizer, and after granulation, it is...

Embodiment 1

[0050] S1 preparation of organic carbon:

[0051] Select 100 kg of yeast fermentation waste liquid by weight, adjust the pH at about 6.0, heat to 80 ° C, add 2 kg of trace elements zinc sulfate, 1 kg of copper sulfate, and 0.8 kg of manganese sulfate, and carry out complexation reaction for 1.5 hours;

[0052] S2: Preparation of mixed bacterial agent:

[0053] 1kg of Bacillus subtilis and 1kg of Paecillopsis lilacinus were selected, and the number of effective viable bacteria was ≥1 billion / g.

[0054] Preparation of S3 functional fertilizer:

[0055] Select 30 parts of urea, 3 parts of ammonium sulfate, 30 parts of monoammonium phosphate, 40 parts of potassium sulfate, 1 part of superphosphate, 0.3 parts of borax, 0.8 parts of magnesium sulfate, 0.1 parts of polyglutamic acid, 0.2 parts of alginic acid, forming agent 1 part, 2 parts of anti-caking powder.

[0056] Put the above raw materials into the granulator, use the conventional granulation process to make fertilizer g...

Embodiment 2

[0059] S1 preparation of organic carbon:

[0060] Select 80 kg of yeast fermentation waste liquid and 80 kg of amino acid fermentation waste liquid by weight, adjust the pH at about 5.0, heat to 100 ° C, add 4.5 kg of trace elements zinc sulfate, 3.0 kg of copper sulfate, and 2.5 kg of manganese sulfate, and carry out complexation reaction 1 Hour;

[0061] S2: Preparation of mixed bacterial agent:

[0062] Select 1kg of Bacillus subtilis, 1kg of actinomycetes, and 1kg of Beauveria bassiana. The number of effective viable bacteria is ≥1 billion / g.

[0063] Preparation of S3 functional fertilizer:

[0064] Select 35 parts of urea, 5 parts of ammonium sulfate, 35 parts of monoammonium phosphate, 40 parts of potassium sulfate, 0.6 part of superphosphate, 0.5 part of borax, 0.6 part of magnesium sulfate, 0.2 part of polyglutamic acid, 0.2 part of polyaspartic acid, 0.1 part of alginic acid, 1.5 parts of forming agent, 1 part of anti-caking oil, and 2 parts of anti-caking powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com