Combined extraction method of different effective active components in citrus peel residues

A technology for citrus peel residue and active ingredients, which is applied in the field of resource utilization of citrus peel residue, and can solve the problems of no large-scale production, lack of comprehensive consideration of extraction methods, and inability to extract.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

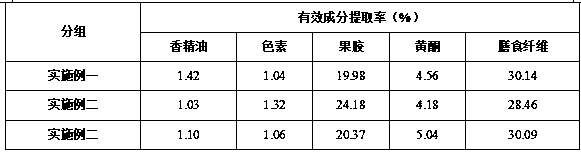

Embodiment 1

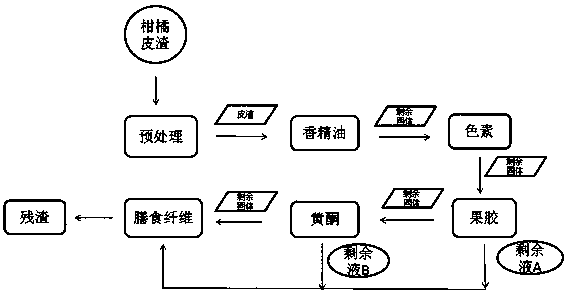

[0038] Use the following method to extract each effective active ingredient in citrus peel (ponkan peel) (the process flow is as follows: figure 1 shown):

[0039] 1) Pretreatment of citrus peels: Dry the citrus peels at 61°C, crush them, pass through a 25-mesh sieve, and then blanch them with hot water at 89°C for 13 minutes to inactivate the enzymes in the citrus peels, and then soak them in distilled water for 1.5 h, to obtain the pretreated citrus peel residue, for subsequent use.

[0040] 2) Extract essential oil: Put the pretreated citrus peel into the NaCl solution with a mass fraction of 4.5% at a mass ratio of 1:11.2, and carry out distillation extraction for 54 minutes to obtain the distilled extract and de-essentially oiled citrus peel. The above operation of distillation and extraction was repeated twice, and the distillation extracts obtained each time were combined together as the distillation extract. Then extract and distill the extract with an extractant (a ...

Embodiment 2

[0046] Use the following method to extract each effective active ingredient in citrus peel (navel orange peel) (the process flow is as follows: figure 1 shown):

[0047] 1) Pretreatment of citrus peels: Dry the citrus peels at 64°C, crush them, pass through a 20-mesh sieve, and then blanch them with hot water at 92°C for 11 minutes to inactivate the enzymes in the citrus peels, and then soak them in distilled water for 80 minutes , to obtain pre-treated citrus peel residue, and set aside.

[0048] 2) Extract essential oil: Put the pretreated citrus peel into the NaCl solution with a mass fraction of 5.0% at a mass ratio of 1:11.6, and carry out distillation extraction for 61 minutes to obtain the distilled extract and de-essentially oiled citrus peel. The above operation of distillation and extraction was repeated twice, and the distillation extracts obtained each time were combined together as the distillation extract. Then use the extractant (a mixture of ether and dichlor...

Embodiment 3

[0054] The following methods are used to extract each effective active ingredient from citrus peel (citrus peel) (the process flow is as follows: figure 1 shown):

[0055] 1) Pretreatment of citrus peels: Dry the citrus peels at 62°C, crush them, pass through a 25-mesh sieve, and then blanch them with hot water at 85°C for 12 minutes to inactivate the enzymes in the citrus peels, and then soak them in distilled water for 100 minutes , to obtain the pretreated citrus peel residue, and set aside.

[0056] 2) Extract essential oil: Put the pretreated citrus peel into the NaCl solution with a mass fraction of 4.8% at a mass ratio of 1:10.9, and carry out distillation extraction for 67 minutes to obtain the distillation extract and de-essential citrus peel. The above operation of distillation and extraction was repeated twice, and the distillation extracts obtained each time were combined together as the distillation extract. Then extract and distill the extract with an extractan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com