Polyurethane resin for breathable insole, preparation method and application

A polyurethane resin and resin technology, which is applied in the field of polyurethane resin for breathable insoles and its preparation and application, can solve the problems of high production cost, and achieve the effects of low cost, saving production cost, and fine and uniform cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

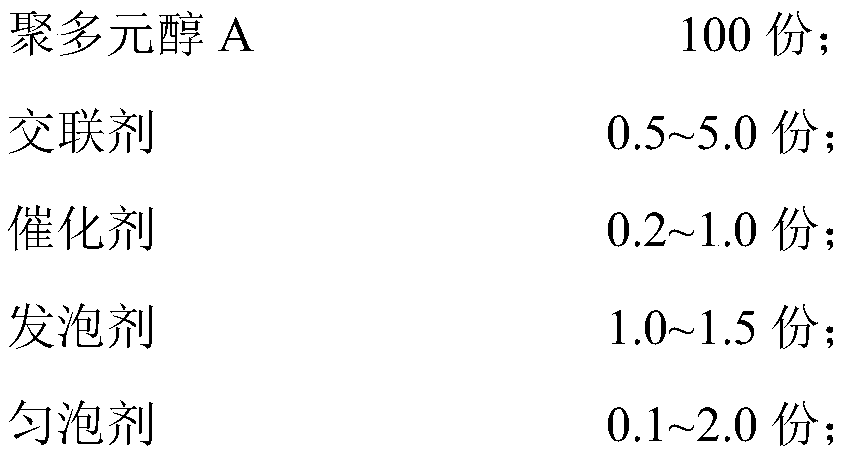

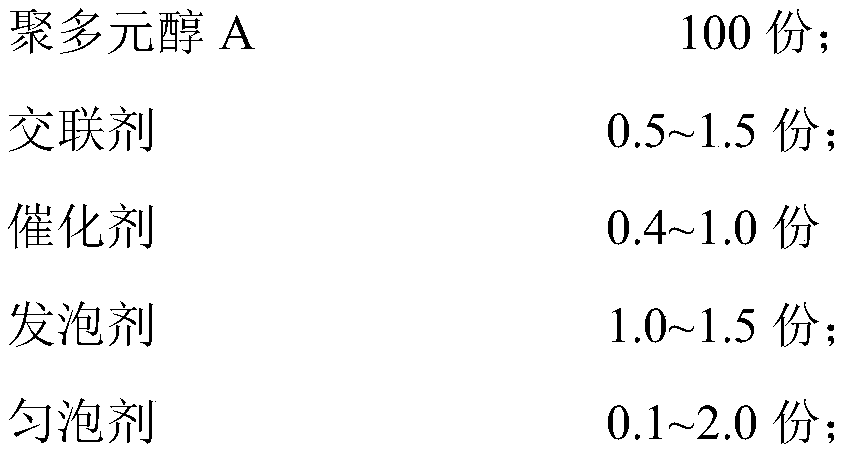

Method used

Image

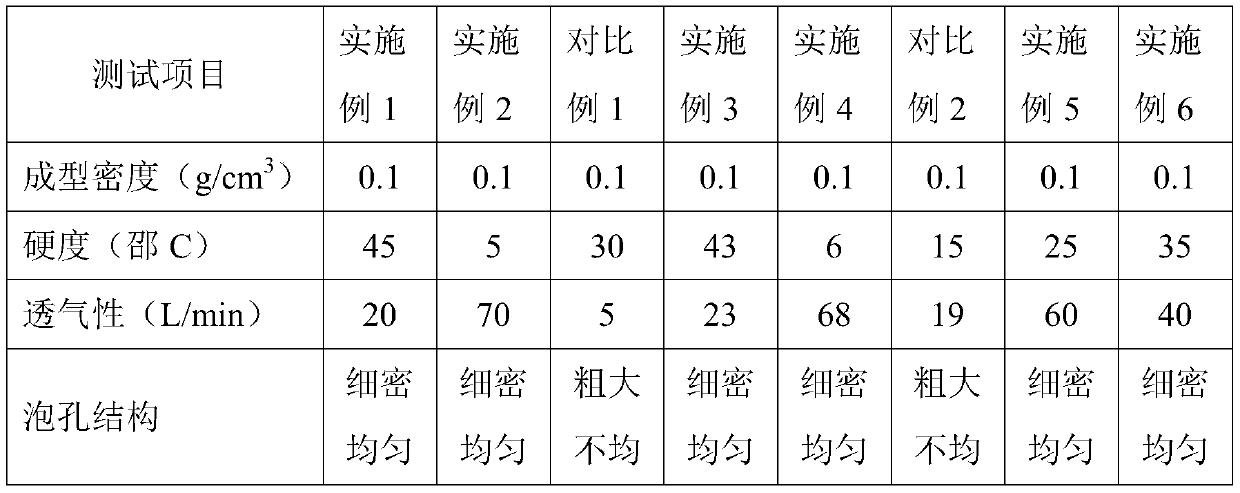

Examples

Embodiment 1

[0055] 58.8kg of polyoxyethylene-propylene oxide triol (number average molecular weight is 6000), 65.9kg of polyoxypropylene triol (number average molecular weight is 1,000), 152.4kg of styrene graft copolymer ethylene oxide-propylene oxide Triol (number average molecular weight is 6000), 1.39kg of ethylene glycol, 0.22kg of triethylenediamine ethylene glycol solution, 0.89kg of 70wt% bis(dimethylaminoethyl) ether and 30wt% shrink The solution of dipropylene glycol, 2.77 kg of water and 0.28 kg of silicone foam stabilizer were reacted at 50°C for 2.5 hours, then cooled to 45°C and mixed for 1.0 hour to obtain the polyurethane resin A component.

[0056] 60.0kg of diphenylmethane diisocyanate, 20.0kg of carbodiimide modified diphenylmethane diisocyanate, 1.0kg of polyethylene oxide-propylene oxide triol (number average molecular weight of 6000) and 0.002kg of Phosphoric acid is reacted at 75°C for 2h to obtain polyurethane resin B1 component.

[0057] 6.0 kg of diphenylmethane diis...

Embodiment 2

[0060] 58.8kg of polyoxyethylene-propylene oxide triol (number average molecular weight is 6000), 65.9kg of polyoxypropylene triol (number average molecular weight is 1,000), 152.4kg of styrene graft copolymer ethylene oxide-propylene oxide Triol (number average molecular weight is 6000), 1.39kg of ethylene glycol, 0.22kg of triethylenediamine ethylene glycol solution, 0.89kg of 70wt% bis(dimethylaminoethyl) ether and 30wt% shrink The solution of dipropylene glycol, 2.77kg of water and 0.28kg of silicone foam stabilizer were reacted at 50°C for 2.5 hours, then cooled to 45°C and mixed for 1.0 hour to obtain polyurethane resin A component.

[0061] 9.19kg of diphenylmethane diisocyanate, 3.06kg of carbodiimide modified diphenylmethane diisocyanate, 0.15kg of polyoxyethylene-propylene oxide triol (number average molecular weight is 6000) and 0.00032kg Phosphoric acid is reacted at 75°C for 2h to obtain polyurethane resin B1 component.

[0062] 74.4 kg of diphenylmethane diisocyanate...

Embodiment 3

[0065] 48.08kg of polyoxyethylene-propylene oxide triol (number average molecular weight of 10000), 120.19kg of polyoxypropylene triol (number average molecular weight of 5000), 33.66kg of acrylonitrile graft copolymerized ethylene oxide-propylene oxide Triol (number average molecular weight is 10000), 2.02kg of ethylene glycol, 1.01kg of triethylenediamine in ethylene glycol solution, 1.01kg of 70wt% bis(dimethylaminoethyl) ether and 30wt% shrink After reacting the solution of dipropylene glycol, 3.03 kg of water and 4.04 kg of silicone foam stabilizer at 50°C for 2.5 hours, the temperature was lowered to 40°C and mixed for 1.5 hours to obtain the polyurethane resin A component.

[0066] Combine 50.8g of diphenylmethane diisocyanate, 12.7kg of carbodiimide modified diphenylmethane diisocyanate, 12.7kg of polyoxyethylene-propylene oxide triol (number average molecular weight of 10,000) and 0.002kg of Phosphoric acid was reacted at 65°C for 3 hours to obtain the polyurethane resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com