A kind of auxiliary agent for processing coal tar and preparation method thereof

A technology of coal tar and additives, applied in tar processing, tar removal through water, petroleum industry, etc., can solve the problems of reducing the quality of coal tar, unstable composition and properties of tar raw materials, and high content of surface active components , to achieve the effects of enhanced full contact, excellent surface activity, and high cleanliness of the aqueous phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

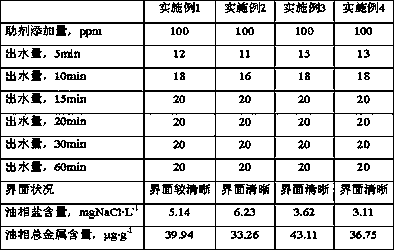

Examples

Embodiment 1

[0027] Mix 100g of triethylenetetramine starter and 350g of xylene and put it into a 2500ml high-pressure reactor equipped with an electric stirrer, and add 0.1g of KOH as a catalyst, turn on the stirrer under preheating conditions at 70°C, and inject After 60g of 4-(2,3-epoxypropyleneoxy)-carbazole, 200g of ethylene oxide EO and 80g of propylene oxide PO, heat up to 125°C, continuously stir and fully react, while adjusting the system pressure to make it Maintained between 0.5~0.6MPa, after ~4 hours of reaction, the pressure in the reactor no longer changes significantly, and the reaction ends. The enriched intermediate product B was obtained through operations such as filtration and vacuum distillation.

[0028] Take 100g of intermediate product B, mix it in 500g of toluene, put it into a 1000ml three-neck flask equipped with a stirrer and a thermometer, add 0.25g of triisopropyl titanate, start stirring and raise the temperature to 65°C, add polymethylacrylate After a total...

Embodiment 2

[0030] Mix 100g of tetraethylenepentamine initiator and 450g of xylene and put it into a 2500ml high-pressure reactor equipped with an electric stirrer, and add 0.1g of KOH as a catalyst, turn on the stirrer under the preheating condition of 70°C, and inject After 65g of 4-(2,3-epoxypropyleneoxy)-carbazole, 250g ethylene oxide EO and 85g propylene oxide PO, the temperature was raised to 135°C, and the reaction was fully stirred continuously, while the system pressure was adjusted to make it Maintained between 0.5~0.6MPa, after ~4 hours of reaction, the pressure in the reactor no longer changes significantly, and the reaction ends. The enriched intermediate product B was obtained through operations such as filtration and vacuum distillation.

[0031]Take 100g of intermediate product B, mix it in 500g of toluene, put it into a 1000ml three-neck flask equipped with a stirrer and a thermometer, add 0.25g of triisopropyl titanate, start stirring and raise the temperature to 65°C, a...

Embodiment 3

[0033] Mix 100g of triethylenetetramine starter and 350g of xylene and put it into a 2500ml high-pressure reactor equipped with an electric stirrer, and add 0.1g of KOH as a catalyst, turn on the stirrer under preheating conditions at 70°C, and inject After 65g of 4-(2,3-epoxypropyleneoxy)-carbazole, 220g of ethylene oxide EO and 90g of propylene oxide PO, the temperature was raised to 125°C, and the reaction was fully stirred continuously, while the pressure of the system was adjusted to make it Maintained between 0.5~0.6MPa, after ~4 hours of reaction, the pressure in the reactor no longer changes significantly, and the reaction ends. The enriched intermediate product B was obtained through operations such as filtration and vacuum distillation.

[0034] Take 100g of intermediate product B, mix it in 500g of toluene, put it into a 1500ml three-necked flask equipped with a stirrer and a thermometer, add 0.25g of triisopropyl titanate, start stirring and raise the temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com