InP quantum dot and preparation method therefor

A technology of quantum dots and quantum efficiency, applied in the field of InP quantum dots and their preparation, can solve the problems of uneven particle size and poor quantum efficiency of quantum dots, and achieve the effects of uniform particle size, reducing loss and improving fluorescence quantum yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In another typical embodiment of the present application, a method for preparing the above-mentioned InP quantum dots is provided. The preparation method includes: step S1, reacting the metal salt and the InP core to obtain an InP core modified by the metal salt; step S2, coating ZnSe on metal salt modified InP x S 1-x Shell or ZnSe / ZnS shell to get InP quantum dots.

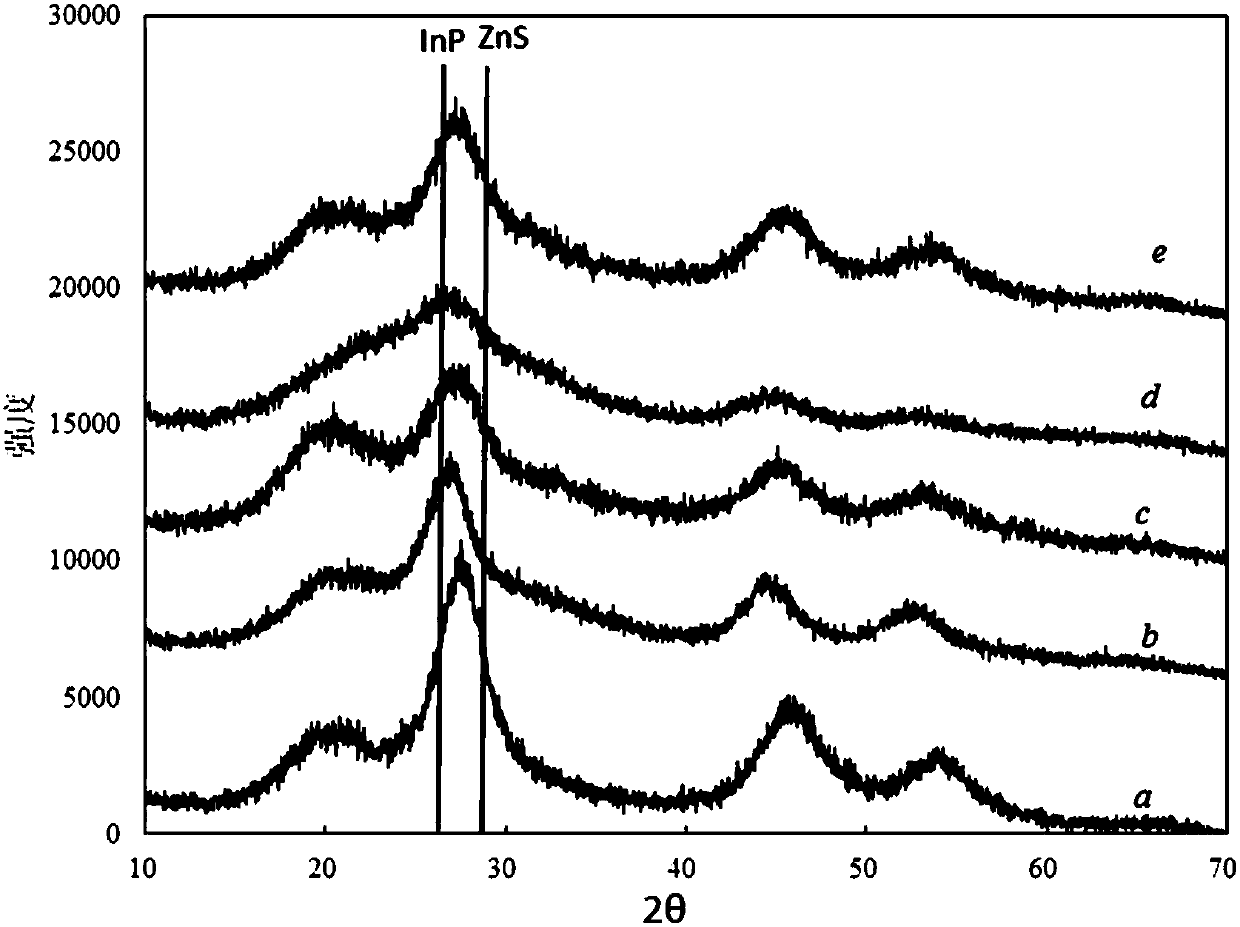

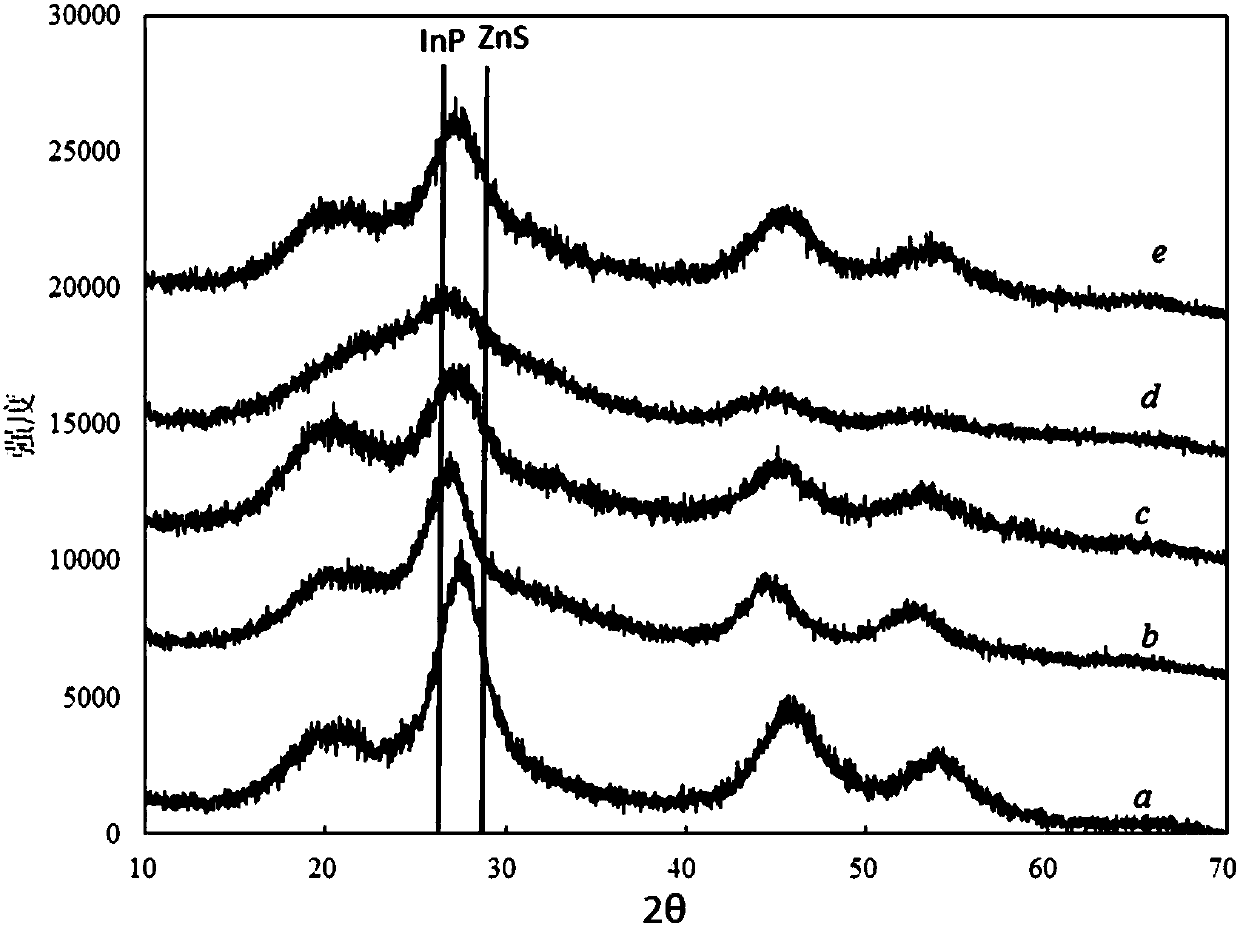

[0030] Use the above-mentioned metal salts to react with InP, so that metal ions enter the lattice of InP, and then coat ZnSe on the InP core modified by metal salts. x S 1-x Shell or ZnSe / ZnS shell, because the lattice constant gap between InP core and ZnSe is small, therefore the shell with S and Se can be coated on the surface of InP core relatively easily, and then make the InP quantum dot of the present application It has high quantum efficiency and stability; at the same time, the obtained InP quantum dot has a half-peak width less than or equal to 50nm, and the particle size of the quantum dot i...

Embodiment 1

[0038] Weigh 57mg (0.2mmol) In(Ac) 3 , 133mg myristic acid, 5g ODE (1-octadecene), vacuumize at 100°C for 2 hours, then heat up to 180°C, inject 0.1mmol (TMS) 3 A mixed solution of P (tris(trimethylsilyl)phosphine) and 0.3ml ODE was kept at 180° C. for 30 minutes to obtain the first system containing InP core.

[0039] Raise the temperature of the first system to 280°C, add GaCl 3 (0.1 mmol), and reacted for 5 min to obtain the second system containing metal salt-modified InP cores. The molar percentage of Ga:In is 0.5.

[0040] Add ZnOA (zinc oleate, 0.5mmol), OLEA (oleylamine, 1mmol), Se-TOP (selenium-trioctylphosphine, 0.1mmol), S-TOP (sulfur-trioctylphosphine, 0.4mmol), reacted for 10min.

[0041] After the reaction was completed, it was lowered to room temperature, extracted three times with methanol to obtain the extract, and the extract was precipitated with acetone and centrifuged to obtain a centrifugal precipitate, and then the centrifugal precipitate was dissolv...

Embodiment 2

[0043] Weigh 57mg (0.2mmol) In(Ac) 3 , 133mg myristic acid, 5g ODE, vacuumize at 100°C for 2 hours, then heat up to 180°C, inject 0.1mmol (TMS) 3 The mixed solution of P and 0.3ml ODE was kept at 180°C for 30min to obtain the first system containing InP.

[0044] Raise the temperature of the first system to 280°C, add ScCl 3 (0.1 mmol) was reacted for 5 min to obtain the second system containing metal salt-modified InP. The molar percentage of Sc:In is 0.5.

[0045] Add ZnOA (zinc oleate 0.5mmol), OLEA (oleylamine 1mmol), Se-TOP (selenium-trioctylphosphine 0.1mmol), S-TOP (sulfur-trioctylphosphine 0.4mmol) to the second system, React for 10 minutes.

[0046] After the reaction was completed, it was lowered to room temperature, extracted three times with methanol to obtain the extract, and the extract was precipitated with acetone and centrifuged to obtain a centrifugal precipitate, and then the centrifugal precipitate was dissolved in toluene to obtain purified InPScZnSe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Half width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com