Palladium-niobium catalyzing film material used for light-adjusting device, light adjusting mirror with material and preparing method of palladium-niobium catalyzing film material

A technology of thin film materials and dimming mirrors, which is applied in metal material coating technology, instruments, optics, etc., can solve problems such as oxidation, poor ductility of Pd, loss of dimming performance, etc., to reduce manufacturing costs and reduce preparation costs , the effect of improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

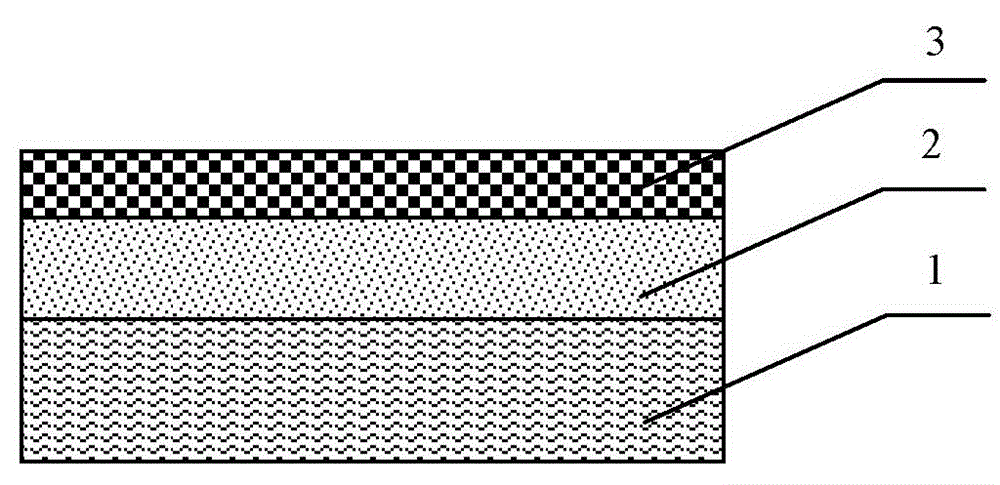

[0035] The palladium-niobium catalytic layer film material is preferably prepared by co-sputtering pure metal Pd and Nb by DC magnetron sputtering. The formation of alloy films with different compositions can be controlled by changing the sputtering power. The thickness of the deposited film is controlled by adjusting the sputtering time to meet the application requirements.

[0036] In the preparation of light-adjusting mirrors, after co-sputtering deposition of light-adjusting layers (such as magnesium alloy films) on the substrate by physical vapor deposition, followed by in-situ co-sputtering deposition of metal palladium and metal niobium to obtain palladium-niobium alloy catalysts layer of thin film material to obtain dimming mirror thin film material. Similarly, the formation of light-adjusting layers and catalytic layers with different components can be controlled by changing the sputtering power, and the thickness of the light-adjusting layers and catalytic layers ca...

Embodiment 1

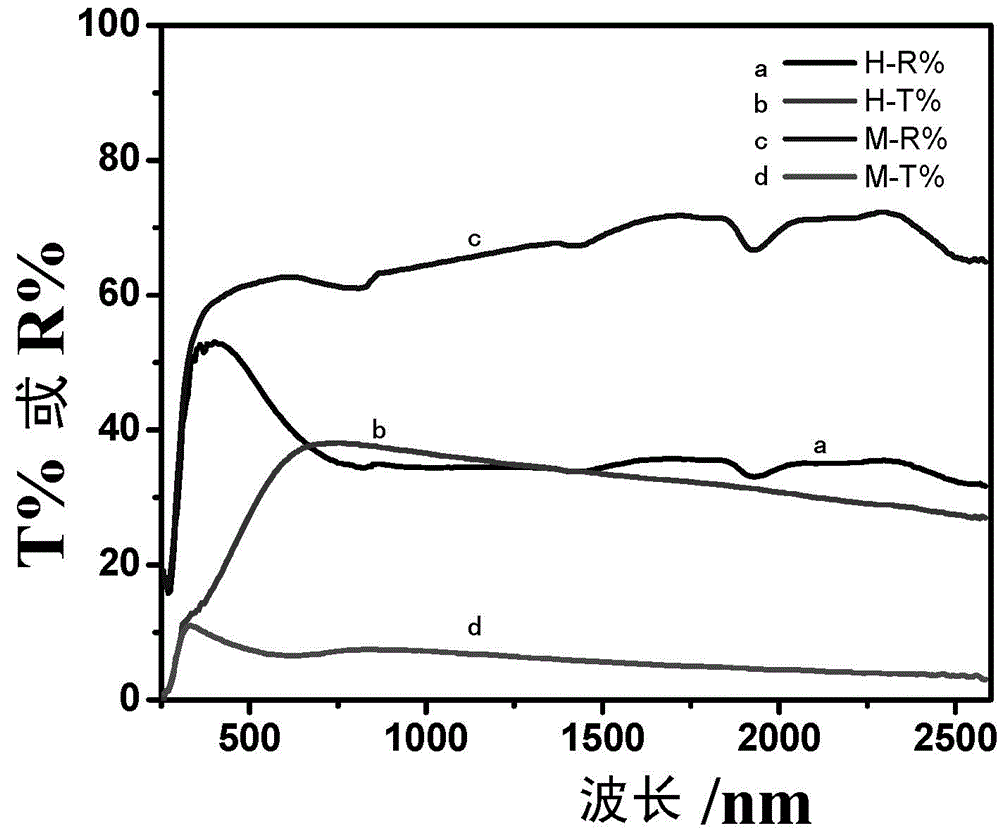

[0044] Embodiment 1: Preparation of dimming mirror

[0045] 1) Substrate cleaning

[0046] First, put the ordinary BK7 substrate in the beaker, and ultrasonically in 0.5mol / L NaOH solution, deionized water, acetone, and deionized water for 10 minutes respectively;

[0047] 2) Preparation of magnesium alloy dimming mirror

[0048] Magnesium alloy dimming mirror film is prepared by DC magnetron sputtering. The magnetron sputtering apparatus includes a sample chamber and a sputtering chamber. The sputtering chamber contains 4 targets, which are pure Mg metal targets (99.99%) , pure Ni metal (99.99%), pure Pd metal (99.99%) and pure Nb metal targets (99.99%). Send the cleaned BK7 substrate into the sputtering chamber, and the background vacuum of the sputtering chamber reaches 10 -5 Below the order of magnitude, adjust the rotation speed of the sample stage to 10r / min; feed high-purity argon gas with a flow rate of 40sccm, adjust the deposition pressure to 0.5Pa, and start depo...

Embodiment 2

[0050] Embodiment 2: the preparation of palladium niobium catalytic film material

[0051] 1) Substrate cleaning

[0052] First place the Si substrate in a beaker and ultrasonically in acetone for 10 minutes;

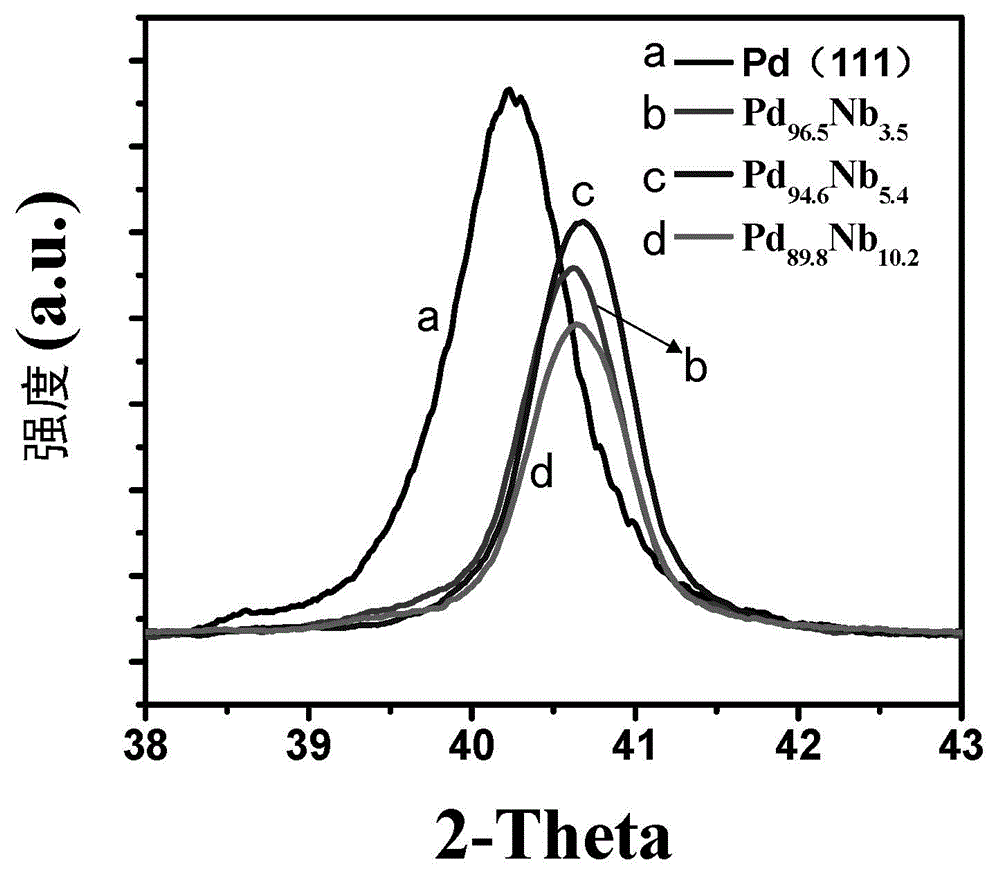

[0053] 2) Preparation of palladium-niobium alloy

[0054] The preparation of the palladium-niobium alloy thin film adopts the method of DC magnetron sputtering. The magnetron sputtering apparatus includes a sample chamber and a sputtering chamber. The sputtering chamber contains 4 targets, which are pure Mg metal target (99.99%), pure Ni metal (99.99%), pure Pd metal (99.99%) and pure Nb metal targets (99.99%), only metal Pd and Nb targets are used here. Send the cleaned Si substrate into the sputtering chamber, and the background vacuum of the sputtering chamber reaches 10 -5 Below the order of magnitude, adjust the rotation speed of the sample stage to 10r / min; feed high-purity argon gas with a flow rate of 40sccm, adjust the deposition pressure to 0.5Pa, and start...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com