A method for reclaiming protein in whey protein or MPC by compound enzyme polymerization coupling ultrafiltration

A whey protein and compound enzyme technology, applied in protein food ingredients, protein food processing, application, etc., can solve the problem that membrane pollution cannot be effectively solved, the functionality of whey protein is not outstanding, and the recovery rate of whey protein is low, etc. To reduce the lactose rejection rate, reduce the frequency of membrane cleaning, and improve the membrane flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

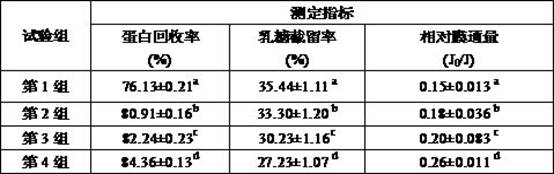

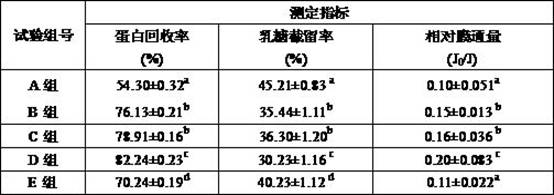

Embodiment 1

[0068] Embodiment 1: A method for recovering protein in whey protein or MPC by composite enzyme polymerization coupled ultrafiltration, which simultaneously improves the recovery rate of protein components in whey protein or MPC, improves membrane flux, and reduces lactose retention rate, Follow the steps below:

[0069] (1) Raw material preparation:

[0070] Take 40ml of cheese whey or MPC dialysate, which can be refrigerated at 4 °C for later use;

[0071] (2) Complex enzyme polymerization:

[0072] Take 40ml of cheese whey or MPC dialysate and put it into a silk bottle, adjust the pH value of cheese whey or MPC dialysate to 5.0 with 0.2N sodium hydroxide and / or 0.2N hydrochloric acid, add 120 U of laccase and 5 mol / l ferulic acid 3-5ml, then place the silk bottle with the mixed solution in a constant temperature water bath, react at 37°C for 1-2h, kill the enzyme, then adjust the pH value of the solution to 8.0 again, Add 160U of transglutaminase and 3-5ml of 20mM DTT, c...

Embodiment 2

[0075] Embodiment 2: A method for recovering protein in whey protein or MPC by composite enzyme polymerization coupled ultrafiltration, which simultaneously improves the recovery rate of protein components in whey protein or MPC, improves membrane flux, and reduces lactose retention rate, Follow the steps below:

[0076] (1) Raw material preparation:

[0077] Take 40ml of cheese whey or MPC dialysate, which can be refrigerated at 4 °C for later use;

[0078] (2) Two-stage pretreatment: the first stage: first raise the temperature to 60-65°C at a rate of 5°C / min, and hold for 20 minutes; the second stage: then raise the temperature to 75 at a rate of 5°C / min -80°C, keep warm for 10 minutes;

[0079] (3) Complex enzyme polymerization:

[0080] Take 40ml of cheese whey or MPC dialysate and put it into a silk bottle, adjust the pH value of cheese whey or MPC dialysate to 5.0 with 0.2N sodium hydroxide and / or 0.2N hydrochloric acid, add 120 U of laccase and 5 mol / l ferulic acid 3...

Embodiment 3

[0083] Embodiment 3: adopt the mode of immortal enzyme.

[0084] A method for recovering protein in whey protein or MPC by composite enzyme polymerization coupling ultrafiltration, the method simultaneously improves the recovery rate of protein components in whey protein or MPC, improves membrane flux, and reduces lactose retention rate, and is carried out according to the following steps :

[0085] (1) Raw material preparation:

[0086] Take 40ml of cheese whey or MPC dialysate, which can be refrigerated at 4 °C for later use;

[0087] (2) Two-stage pretreatment: the first stage: first raise the temperature to 60-65°C at a rate of 5°C / min, and hold for 20 minutes; the second stage: then raise the temperature to 75 at a rate of 5°C / min -80°C, keep warm for 10 minutes;

[0088] (3) Complex enzyme polymerization:

[0089] Take 40ml of cheese whey or MPC dialysate and put it into a silk bottle, adjust the pH value of cheese whey or MPC dialysate to 5.0 with 0.2N sodium hydrox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com