Method for starting nitric oxide biological absorption tower by spherical non-woven fabric filling

A technology of nitric oxide and spherical fillers, applied in chemical instruments and methods, separation methods, anaerobic digestion treatment and other directions, can solve the problems of high investment and operation costs, generation of greenhouse gases, easy deactivation of catalysts, etc., and achieve low operating costs. , absorption efficiency improvement, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions (and accompanying drawings).

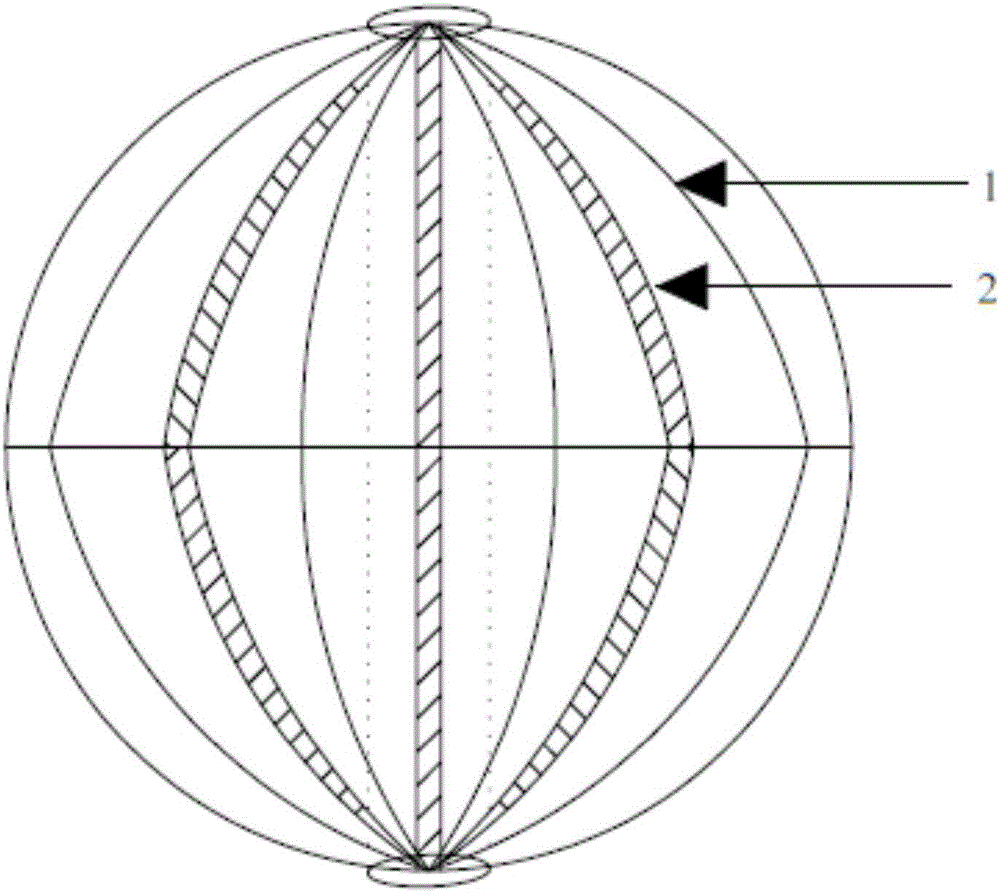

[0020] A tower-type anammox reactor for absorbing nitric oxide started with a non-woven spherical packing.

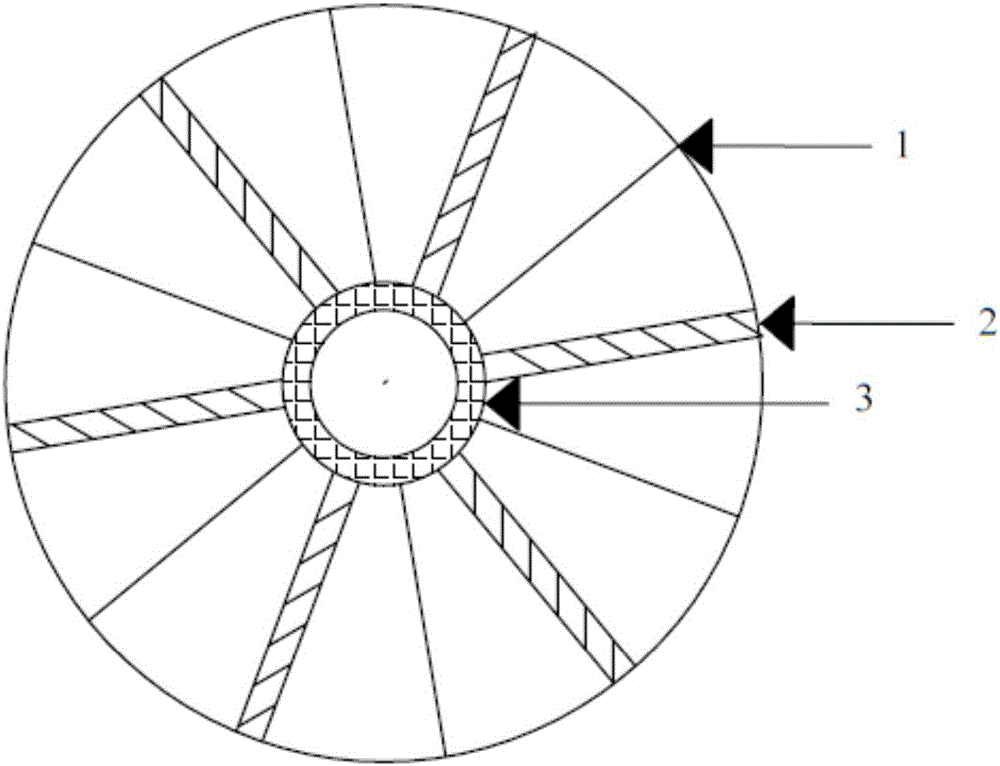

[0021] The filler is a small ball of 25mm*20mm, and the structure of the filler is as follows figure 1 As shown, the reactor is a tower anaerobic ammonium oxidation reactor. The running time of one cycle is 150 days. When the reactor is started, the NH 4 + -N concentration is 45-55mg / L; add potassium dihydrogen phosphate, set PO 4 3- The concentration is 18-22mg / L, add potassium bicarbonate, set the concentration to 500mg / L, add inorganic salt, set Na + The concentration is 8-12mg / L, K + The concentration is 12-16mg / L, Mg + The concentration is 18-22mg / L, adding Fe(II)EDTA, the concentration is 0.05mol / L.

[0022] The tower-type anammox reactor is made of plexiglass in a cylindrical shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com