Quaternized chitosan modified bentonite adsorption material, preparation thereof and application of quaternized chitosan modified bentonite adsorption material in adsorption of lead ions in waste water

A technology of quaternary ammonium chitosan and adsorption materials, applied in the direction of adsorption of water/sewage treatment, other chemical processes, chemical instruments and methods, etc., can solve the problems of poor adsorption performance of bentonite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

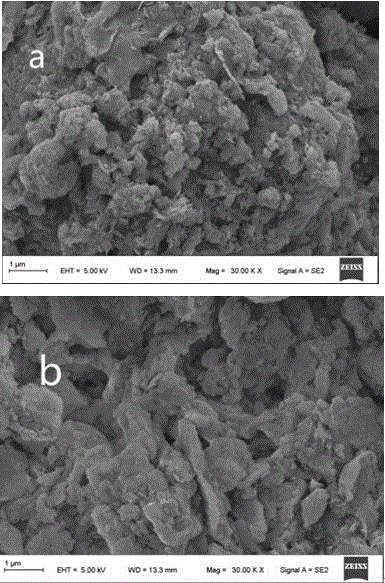

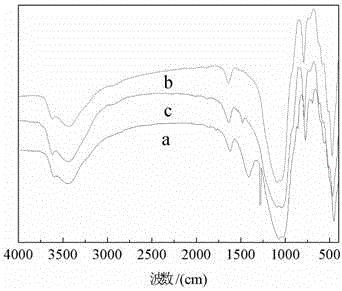

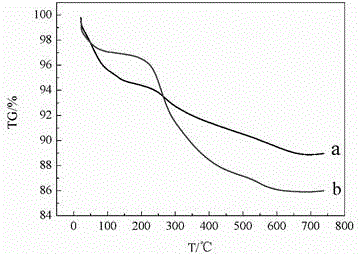

[0055] (1) Preparation of Na-BT: Take 2g of bentonite (BT) dry powder, add 100ml of distilled water, heat to boiling, and stir to form a paste. Then add 2g Na 2 CO 3 , put it on a magnetic stirrer and stir for 3 hours, centrifuge, pour off the supernatant, wash with distilled water and ethanol three times respectively, put it in a vacuum drying oven, after 48 hours, take out the sample and grind it to get Na-BT, and set aside;

[0056] (2) Preparation of CTS-Na-BT: Weigh 1g of chitosan (CTS), dissolve in 1% acetic acid solution, sonicate for 20min, heat and stir for 30min, then add 3g of sodium bentonite, stir for 5h, centrifuge , pour off the supernatant, wash 3 times with distilled water and absolute ethanol, put it in a vacuum drying oven, and after 48 hours, take out the sample and grind it to obtain CTS-Na-BT, which is set aside;

[0057] (3) Preparation of GTMAC-CTS-Na-BT: Weigh 2g of CTS-Na-BT into a 250ml round bottom flask, add 60ml of distilled water, heat to boil,...

Embodiment 2

[0060] (1) Preparation of Na-BT: Weigh 1g of bentonite (BT) dry powder, add 100ml of distilled water, heat to boiling, and stir to form a paste. Then add 2g Na 2 CO 3 , put it on a magnetic stirrer and stir for 2 hours, centrifuge, pour off the supernatant, wash with distilled water and ethanol three times respectively, put it in a vacuum drying oven, after 24 hours, take out the sample and grind it to get Na-BT, and set aside;

[0061] (2) Preparation of CTS-Na-BT: Weigh 1g of chitosan (CTS), dissolve in 1% acetic acid solution, sonicate for 60min, heat and stir for 60min; then add 2g of sodium bentonite, stir for 5h, centrifuge , pour off the supernatant, wash 3 times with distilled water and absolute ethanol, put it in a vacuum drying oven, and after 24 hours, take out the sample and grind it to obtain the preparation of CTS-Na-BT, which is set aside;

[0062] (3) Preparation of GTMAC-CTS-Na-BT: Weigh 2g of CTS-Na-BT into a 250ml round bottom flask, add 80ml of distilled...

Embodiment 3

[0065] (1) Preparation of Na-BT: Weigh 3g of bentonite (BT) dry powder, add 100ml of distilled water, heat to boiling, and stir to form a paste. Then add 2g Na 2 CO 3 , placed on a magnetic stirrer and stirred for 5 hours, centrifuged, poured off the supernatant, washed 3 times with distilled water and ethanol respectively, put it in a vacuum drying oven, and after 48 hours, took out the sample and ground it to obtain Na-BT;

[0066] (2) Preparation of CTS-Na-BT: Weigh 2g of chitosan (CTS), dissolve in 1% acetic acid solution, sonicate for 40min, stir for 60min, then add 2g of sodium bentonite, stir for 5h, centrifuge, Pour off the supernatant, wash 3 times with distilled water and absolute ethanol, put it in a vacuum drying oven, and after 48 hours, take out the sample and grind it for later use;

[0067] (3) Preparation of GTMAC-CTS-Na-BT: Weigh 1g of CTS-Na-BT into a 250ml round bottom flask, add 100ml of distilled water, heat, boil, then add 3g (2,3-epoxy Propyl) trimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com