A kind of chitosan/persimmon tannin composite material and its preparation method and application in recycling germanium

A composite material and chitosan technology, applied in chemical instruments and methods, other chemical processes, water/sewage treatment, etc., can solve problems such as increased oxygen consumption in water, reduced adsorption capacity, and short treatment cycle, and achieve cost reduction , easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 A kind of chitosan / persimmon tannin composite material

[0029] (1) Preparation method

[0030] 1) Take 2g of chitosan (CS) in a three-necked flask, add 40mL of 50% (v / v) ethanol solution, then drop in 4g of epichlorohydrin solution, react at 80°C for 3h, cool, and filter with suction , first wash with ethanol, and then wash with deionized water until neutral to obtain the intermediate product CS-Cl.

[0031] 2) Put 4g of persimmon tannin in another reaction vessel, add 80mL of deionized water, adjust the pH to 10 with NaOH, add the intermediate product CS-Cl, and then heat and stir the mixture at 45°C for 6h, Filter, wash with dilute HCl, and then wash with deionized until neutral. After the product was dried in an oven at 50°C for 24 hours, it was ground and sieved to finally obtain a chitosan / persimmon tannin composite material CS-Cl-PT with a particle size of 100-150 μm.

[0032] (2) Results

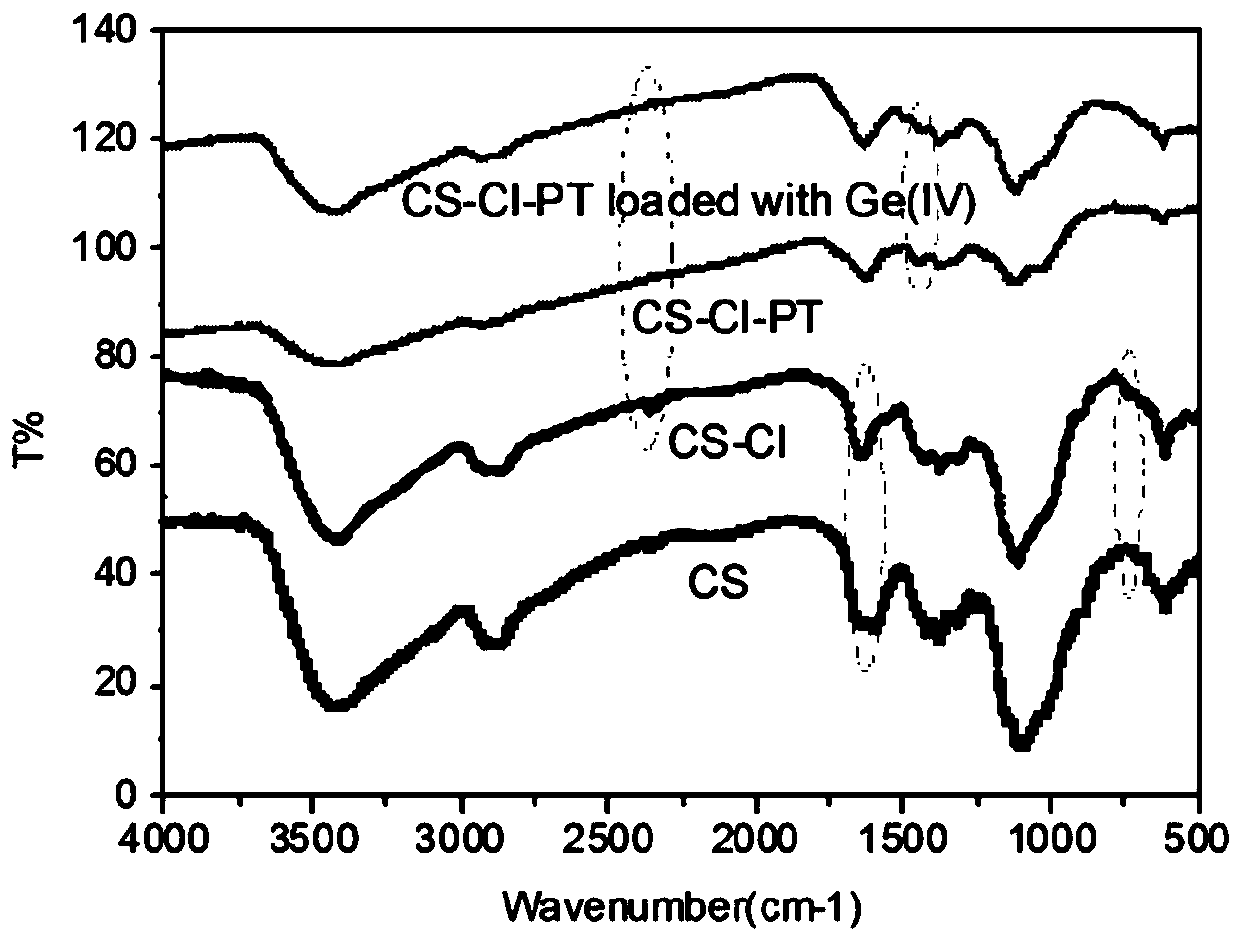

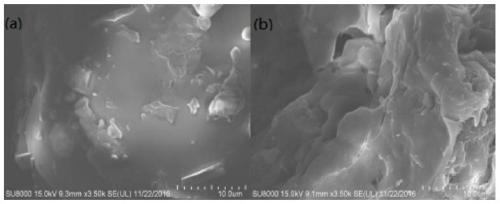

[0033] 1) figure 1 Infrared spectra of CS, CS-Cl, CS-Cl...

Embodiment 2

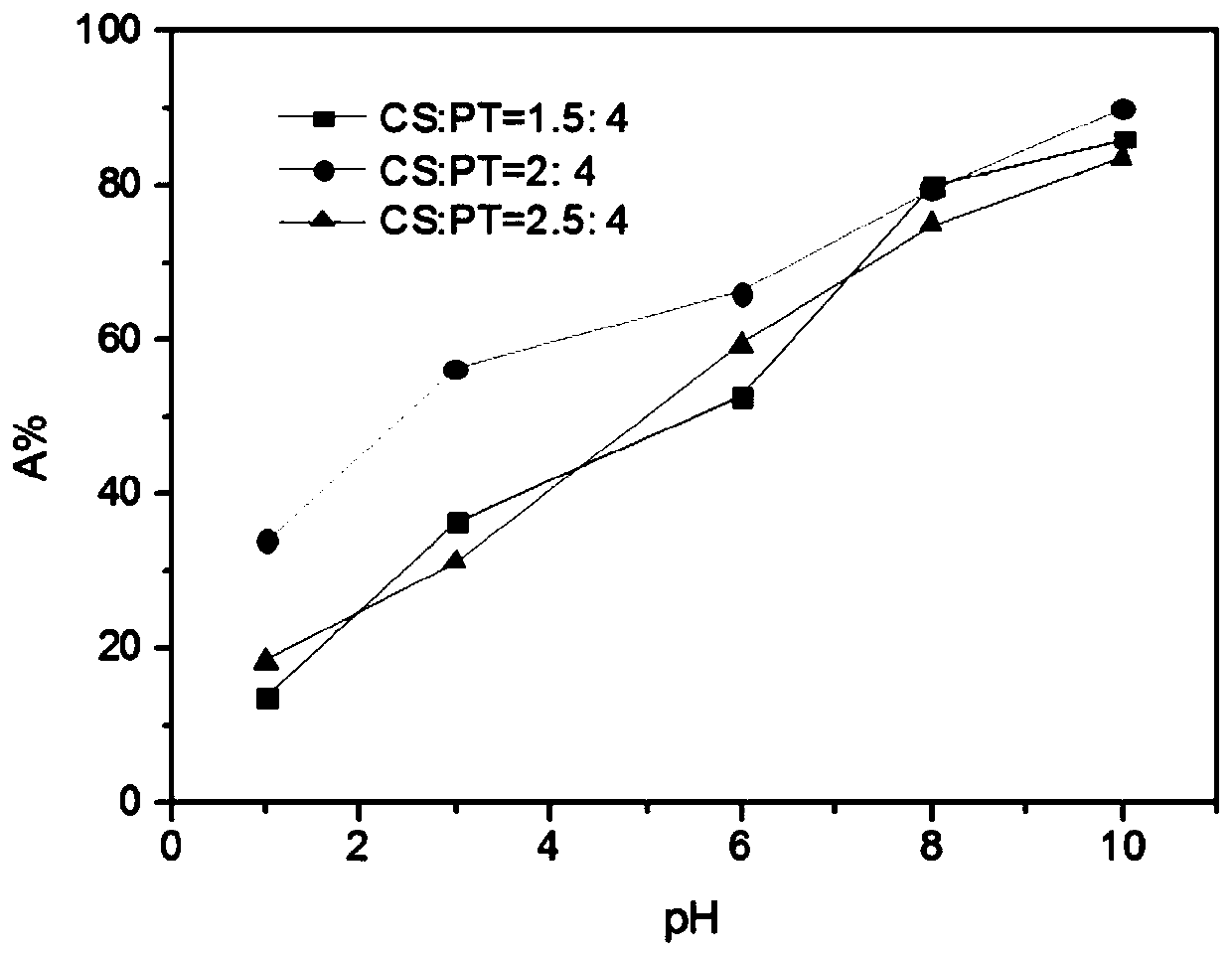

[0035] Embodiment 2 A kind of chitosan / persimmon tannin composite material is to the adsorption effect of germanium under different acidities

[0036] (1) Preparation method

[0037] 1) Take 1.5g, 2g, and 2.5g of chitosan in three three-necked flasks, add 40mL, 50% (v / v) ethanol solution, then drop 4g of epichlorohydrin, and react at 80°C for 3h , cooled, suction filtered, washed with ethanol first, and then washed with deionized water until neutral to obtain the intermediate product CS-Cl.

[0038]2) Put 4 g of persimmon tannins in 3 different reaction vessels, add 80 mL of deionized water to each, adjust the pH to 10 with NaOH, add the intermediate product CS-Cl obtained above, and put the mixture at 45°C After heating and stirring for 6 h, it was filtered with suction, washed with dilute HCl, and then washed with deionized water until neutral. Three different products were dried in an oven at 50°C for 24 hours, then ground and sieved to obtain chitosan / persimmon tannin co...

Embodiment 3

[0042] Embodiment 3 A kind of chitosan / persimmon tannin composite material separates germanium from the arsenic solution containing high concentration

[0043] The existing pH=10 mixed material solution of 1ppmAs and 1ppmGe, the mixed material solution of 10ppmAs and 1ppmGe, the mixed material solution of 50ppmAs and 1ppmGe, the mixed material solution of 80ppmAs and 1ppmGe, the mixed material solution of 100ppmAs and 1ppmGe, respectively take 10mL of the above-mentioned Add 10 mg of the chitosan / persimmon tannin composite material prepared in Example 1 to the feed solution, shake it for 24 hours, filter it, and measure the concentrations of the stock solution and the filtrate. The result is as Figure 4 shown.

[0044] Depend on Figure 4 It can be seen that as the content of As(III) in the solution increases, the adsorption amount of Ge(IV) is hardly affected. Therefore, it can be concluded that the concentration ratio of As(III) and Ge(IV) in the solution Within 100:1, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com