Catalyst for eliminating ozone under room temperature and ambient moisture and preparation method of catalyst

A catalyst, room temperature technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., can solve the problem of high catalyst cost, low ozone elimination rate, and unfavorable promotion and use and other problems, to achieve the effect of large specific surface area, cost reduction and high elimination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

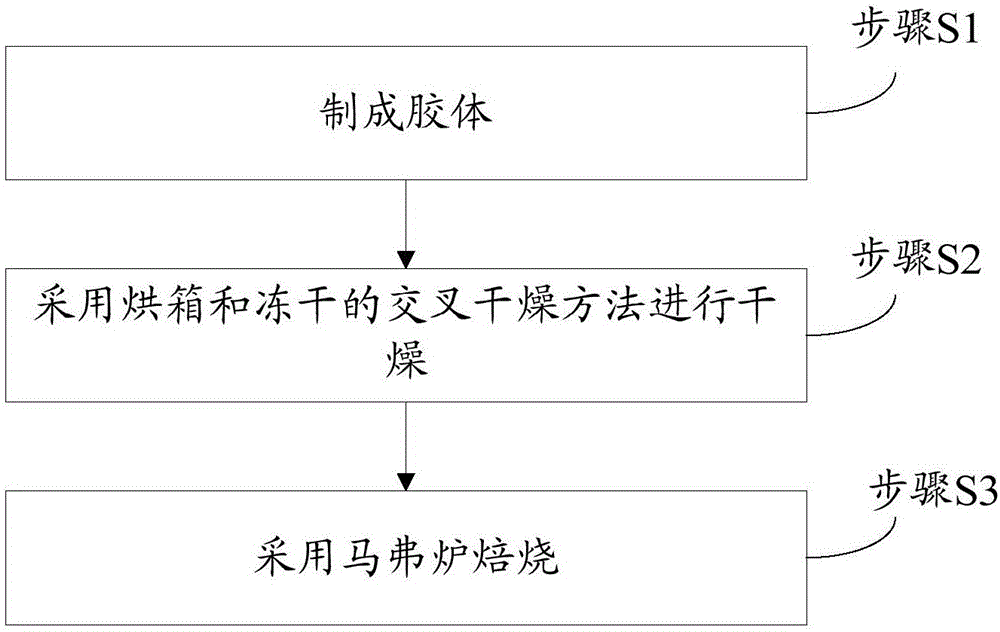

Method used

Image

Examples

Embodiment 2

[0029] Raw materials: the carrier is a mixture of aluminum oxide and ceria; the active component of noble metal is palladium; the additive component is sodium nitrate;

[0030] Preparation:

[0031] Step S1, grinding 0.1 g of the precious metal active component palladium into a 400-mesh fine powder, putting the fine powdered palladium into water, ultrasonically dispersing for 20 minutes, and then adding the auxiliary component sodium nitrate to the solution, the sodium content of which is 0.09g, palladium is mixed with the auxiliary component, ultrasonically reacted for 2 hours, and colloid is made;

[0032] Step S2, disperse 100g of the selected carrier into the above-mentioned colloid, place it in a 100-degree water bath for 50 hours, after the deposition is complete, filter and wash, put the filter cake in an oven, the initial temperature of the oven is 70 degrees, press 0.2 degrees / Make the oven temperature rise to 90 degrees at a heating rate of 1 minute, and dry at 90 ...

Embodiment 3

[0036] Raw materials: the carrier is a mixture of ceria and nickel oxide; the active component of noble metal is palladium; the auxiliary component is potassium oxide;

[0037] Preparation:

[0038] In step S1, 0.01 g of the noble metal active component palladium is ground into a 400-mesh fine powder, and the fine powdered palladium is put into water, ultrasonically dispersed for 25 minutes, and then, the auxiliary component potassium oxide is added to the solution, and the potassium content is 0.10g, palladium is mixed with the auxiliary component, ultrasonically reacted for 2 hours, and colloid is made;

[0039] Step S2, disperse 100g of the selected carrier into the above colloid, place it in an 80 degree water bath for 40 hours, after the deposition is complete, filter and wash, put the filter cake in an oven, the initial temperature of the oven is 70 degrees, press 0.2 degrees / Make the oven temperature rise to 90 degrees at a heating rate of 1 minute, and dry at 90 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com