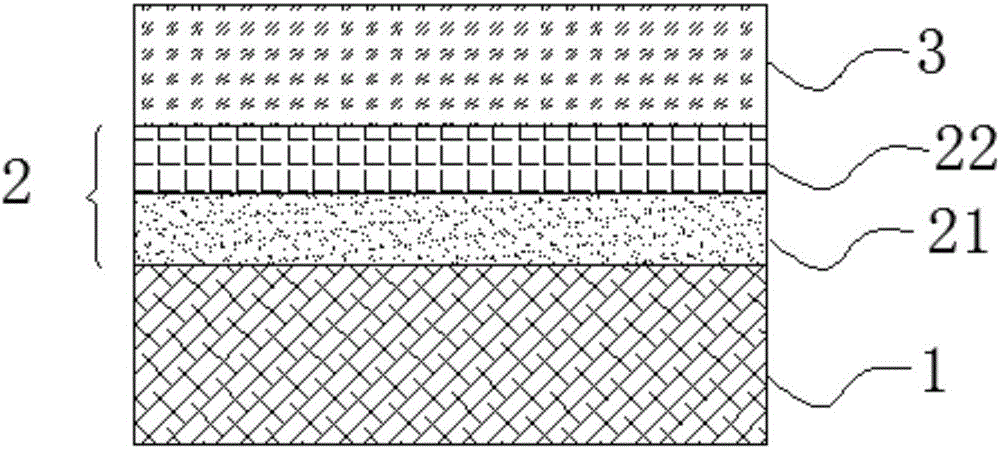

Waterproof, fireproof, and thermal insulation composite plate and preparation method thereof

A technology of thermal insulation composite board and fireproof layer, which is applied to chemical instruments and methods, layered products of hydraulic materials, building elements, etc., and can solve the problem of unsatisfactory thermal insulation efficiency, weak waterproof and anti-electricity functions, and hollowing out. and other problems, to achieve the effect of superior performance, reasonable structure and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The heat-insulating and fire-proof nano-layer includes the following raw materials in parts by weight: 12 parts of glass filaments, 17 parts of aluminum silicate fibers, 70 parts of hollow microsphere nanomaterials, 15 parts of glue, and 15 parts of aromatized powder. 6 parts and expanded perlite is 8 parts;

[0031] The hollow microbead nanomaterials include silicon dioxide, aluminum oxide, magnesium oxide and ferric oxide, and the mass percentages of each component are as follows: the silicon dioxide is 65%, the aluminum oxide is 28% %, the magnesium oxide is 5% and the ferric oxide is 2%.

[0032] The waterproof and anti-cracking layer includes the following raw materials in parts by weight: 42 parts of ordinary portland cement, 48 parts of fine sand, 16 parts of fly ash, 4 parts of mica powder, and 1 part of waterproofing agent for Laoal mortar And cement mortar defoamer is 0.2 parts.

Embodiment 2

[0033] Embodiment 2: The heat-insulating and fire-proof nano-layer includes the following raw materials in parts by weight: 10 parts of glass fiber, 15 parts of aluminum silicate fiber, 65 parts of hollow microsphere nanomaterial, 18 parts of glue, and 18 parts of aromalysis powder. 5 parts and expanded perlite is 7 parts;

[0034] The hollow microbead nanomaterials include silicon dioxide, aluminum oxide, magnesium oxide and ferric oxide, and the mass percentages of each component are as follows: the silicon dioxide is 60%, the aluminum oxide is 35% %, the magnesium oxide is 4% and the ferric oxide is 1%.

[0035] The waterproof and anti-cracking layer includes the following raw materials in parts by weight: 50 parts of ordinary Portland cement, 40 parts of fine sand, 18 parts of fly ash, 5 parts of mica powder, and 1.5 parts of Laoale mortar waterproofing agent And cement mortar defoamer is 0.3 parts.

Embodiment 3

[0036] Embodiment 3: The heat-insulating and fire-proof nano-layer includes the following raw materials in parts by weight: 13 parts of glass filaments, 20 parts of aluminum silicate fibers, 68 parts of hollow microsphere nanomaterials, 20 parts of glue, and 20 parts of aromalysis powder. 7 parts and expanded perlite is 9 parts;

[0037] The hollow microbead nanomaterials include silicon dioxide, aluminum oxide, magnesium oxide and ferric oxide, and the mass percentages of each component are as follows: the silicon dioxide is 70%, the aluminum oxide is 25% %, the magnesium oxide is 3% and the ferric oxide is 2%.

[0038] The waterproof and anti-cracking layer includes the following raw materials in parts by weight: 48 parts of ordinary Portland cement, 46 parts of fine sand, 15 parts of fly ash, 8 parts of mica powder, and 2 parts of Laoal mortar waterproofing agent And cement mortar defoamer is 0.4 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com