Method for preparing industrial silicon carbon reducing agent through coordination of biomass charcoal and activated petroleum coke

A technology for biomass charcoal and biomass raw materials, which is applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of occupying storage space and destruction, achieve high reaction activity, reduce production costs, and improve silica reduction. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

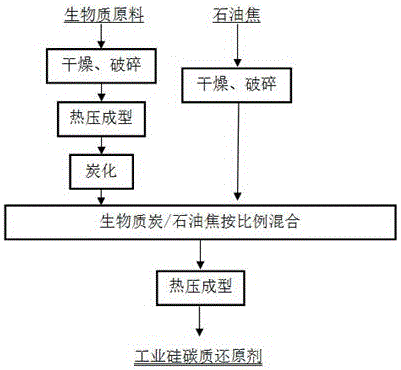

[0031] Embodiment 1: as figure 1 Shown, a kind of method that biochar synergistically activates petroleum coke to prepare industrial silicon carbonaceous reductant, concrete steps are as follows:

[0032] (1) Dry and crush biomass mixed raw materials such as rice husks, walnut shells, and corn stalks until the particle size is less than 30mm. Under the conditions of temperature 80°C and pressure 50MPa, hot pre-press molding, in which there is one in the middle of the profile A through hole with a diameter of 30mm;

[0033] (2) Under the condition of a heating rate of 5°C / min, heat the profile obtained in step (1) to 250°C and carry out carbonization treatment for 240 minutes. Thoroughly; cool to room temperature, crush until the particle size is not greater than 0.2mm to obtain biochar, the mass percentage of biochar components is 75% fixed carbon, 15% volatile matter, 3% moisture, and less than 4% ash; The specific resistance is 5500µΩ m;

[0034] (3) Dry the petroleum cok...

Embodiment 2

[0037] Embodiment 2: as figure 1 Shown, a kind of method that biochar synergistically activates petroleum coke to prepare industrial silicon carbonaceous reductant, concrete steps are as follows:

[0038] (1) Dry and crush biomass mixed raw materials such as pine nut shells, millet stalks, and corn stalks until the particle size is less than 28mm, and heat pre-press them into profiles at a temperature of 90°C and a pressure of 40MPa, in which there are 2 diameters in the middle of the profile 10mm through hole;

[0039] (2) Under the condition of a heating rate of 10°C / min, heat the profile obtained in step (1) to 500°C and carry out carbonization treatment for 200 minutes. Thoroughly; cooled to room temperature, crushed until the particle size is not greater than 0.2mm to obtain biochar, the mass percentage of biochar components is 80% fixed carbon, 13% volatile matter, 3% moisture, and less than 0.4% ash; The specific resistance is 5200µΩ m;

[0040] (3) Dry the petroleum...

Embodiment 3

[0043] Embodiment 3: as figure 1 Shown, a kind of method that biochar synergistically activates petroleum coke to prepare industrial silicon carbonaceous reductant, concrete steps are as follows:

[0044](1) Dry and crush biomass mixed raw materials such as bagasse, corncobs and wheat straws until the particle size is less than 25mm, and heat pre-press them into profiles at a temperature of 100°C and a pressure of 30MPa, in which there are 2 diameters in the middle of the profiles 20mm through hole;

[0045] (2) Under the condition of a heating rate of 15°C / min, heat the profile obtained in step (1) to 600°C and carry out carbonization treatment for 180 minutes. Thoroughly; cool to room temperature, crush until the particle size is not greater than 0.2mm to obtain biochar, the mass percentage of biochar components is 65% fixed carbon, 20% volatile matter, 8% moisture, and less than 3% ash; The specific resistance is 6000µΩ m;

[0046] (3) Dry the petroleum coke, and the cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Broken particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com