Granular sludge-based integrated anaerobic ammonium oxidation denitrification reactor and method

An anaerobic ammonia oxidation and granular sludge technology, applied in the field of sewage biological treatment, can solve the problems of flocculent sludge floating, deterioration of effluent quality, etc., and achieve the effect of fast settling speed, optimization of microbial distribution structure, and promotion of elutriation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

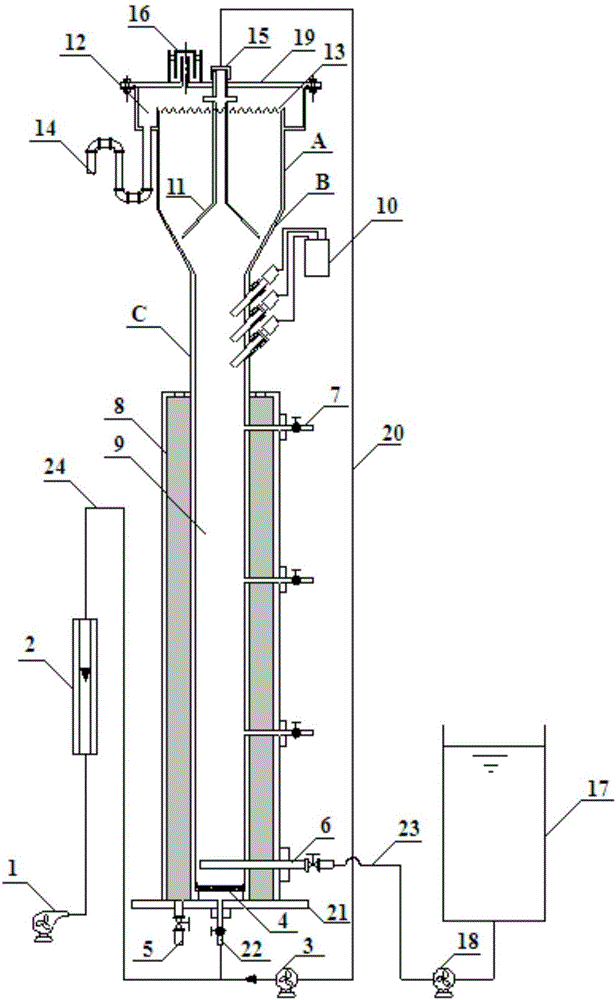

[0023] Specific Embodiment 1: In this embodiment, an integrated anammox denitrification reactor dominated by granular sludge, the reactor includes an aeration pump 1, a flow meter 2, an aeration disc 4, a vent pipe 5, and a water inlet pipe 6 , sampling port 7, water bath jacket 8, reaction tube 9, on-line monitor 10, three-phase separator 11, annular water outlet 12, zigzag end face 13, water outlet pipe 14, air outlet pipe 15, water-sealed exhaust cylinder 16, inlet The bucket 17 and the water inlet pump 18 are characterized in that the reaction tube 9 is provided with a separation section A, a transition section B and a reaction section C from top to bottom, the inner diameter of the reaction section C is smaller than the inner diameter of the separation section A, and the upper end surface of the separation section A is along the The periphery is provided with a zigzag end face 13, the upper end of the separation section A is provided with an annular water outlet 12 along t...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that the circulation pipe 20 is provided with a circulation pump 3 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that a water inlet pump 18 is provided between the water inlet barrel 17 and the water inlet pipe 6 . Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com