A glass clarifying agent for high borosilicate glass and its preparation method and application

A technology of silicate glass and clarifying agent, which is applied in the field of glass clarifying agent for high borosilicate glass and its preparation, and composite glass clarifying agent, which can solve the problem of difficult production technology and no heat-resistant borosilicate float method Production line and other problems, to achieve good clarification effect, enhance clarification ability, and reduce coloring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

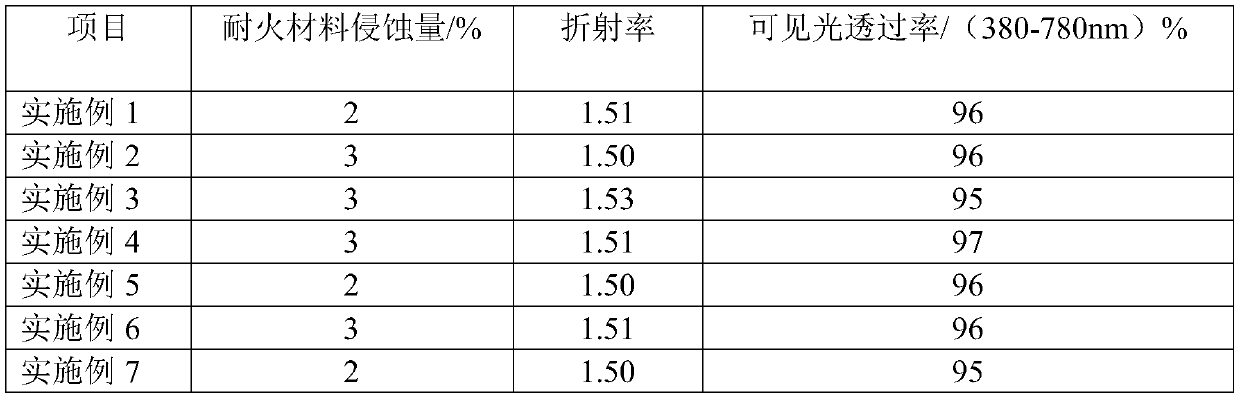

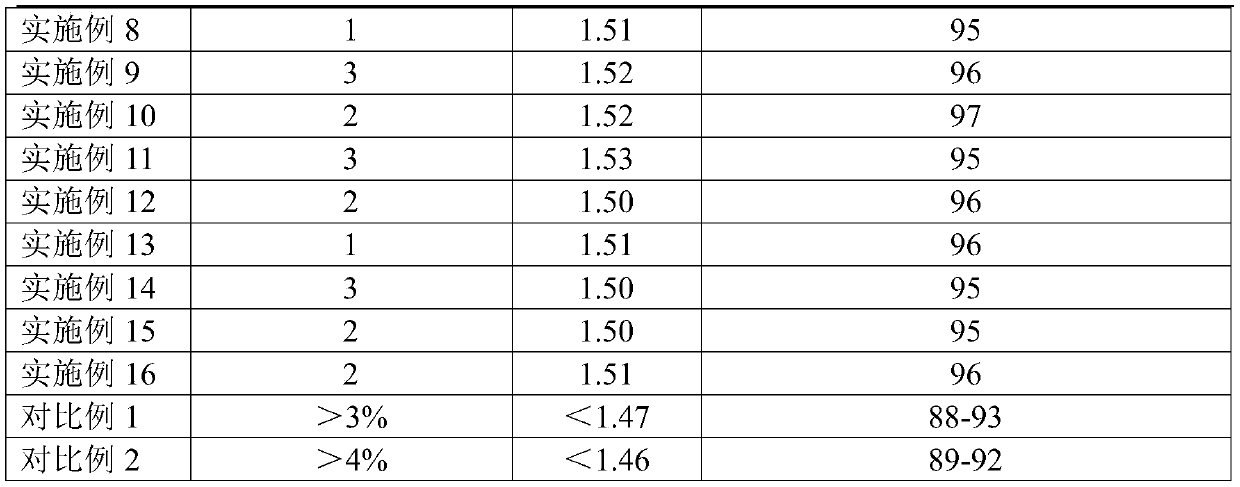

Examples

Embodiment 1

[0021] A glass clarifying agent for high borosilicate glass, comprising the following components: 4.5 parts of sodium sulfate, 0.9 parts of cerium oxide, 0.3 parts of lanthanum oxide, 0.8 parts of tin dioxide, 0.9 parts of carbon powder, and 4.5 parts of sodium chloride.

[0022] The clarification effect of the glass added with the clarifier of the present invention after cooling and molding is that there are few large and small bubbles, and the glass is slightly yellow.

Embodiment 2

[0024] A glass clarifying agent for high borosilicate glass, comprising the following components: 5.0 parts of sodium sulfate, 1.1 parts of cerium oxide, 0.4 parts of lanthanum oxide, 0.7 parts of tin dioxide, 1 part of carbon powder, and 4.0 parts of calcium fluoride.

[0025] The clarification effect of the glass added with the clarifier of the present invention after cooling and forming is that bubbles of all sizes are few and colorless.

Embodiment 3

[0027] A glass clarifying agent for high borosilicate glass, comprising the following components: 5.4 parts of sodium sulfate, 1.3 parts of cerium oxide, 0.5 parts of lanthanum oxide, 0.6 parts of tin dioxide, 1.1 parts of carbon powder, and 5.0 parts of sodium fluorosilicate .

[0028] The clarification effect of the glass added with the clarifier of the present invention after cooling and molding is that there are few large and small bubbles, and the glass is slightly yellow.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com