Slow-release fertilizer

A technology of slow-release fertilizers and raw materials, applied in the field of slow-release fertilizers, can solve the problems of increased labor intensity and input costs, economic losses and waste of resources, and low nutrient utilization, so as to reduce the cost of fertilization operations, improve cold resistance, and improve Effects on Crop Yield and Product Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

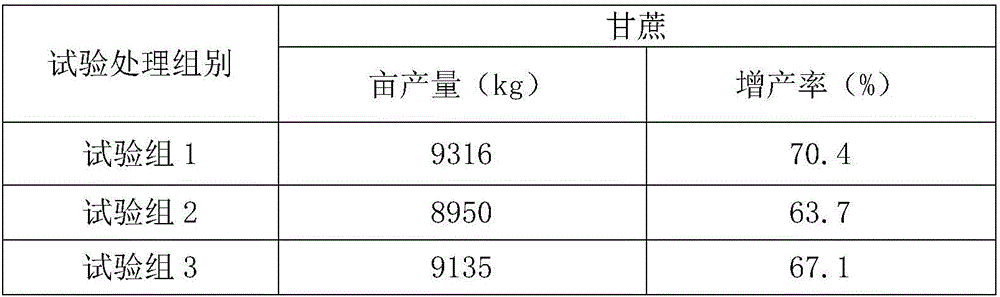

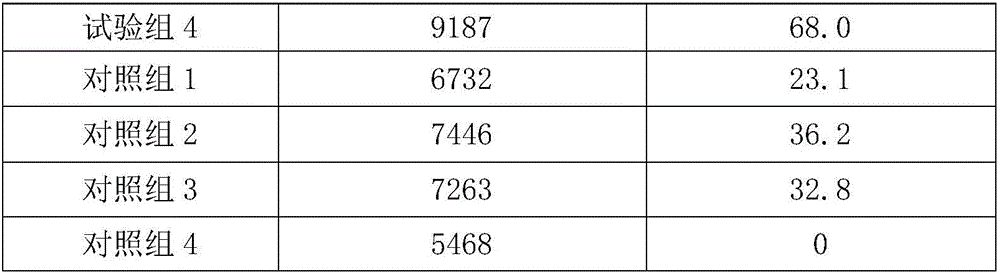

Embodiment 1

[0012] A slow-release fertilizer, consisting of the following raw materials in parts by weight: 25 parts of urea, 22 parts of superphosphate, 20 parts of potassium sulfate, 0.06 part of sodium octaborate tetrahydrate, 0.3 part of zinc sulfate, 0.15 part of iron sulfate, ammonium molybdate 0.04 parts, 0.2 parts of magnesium sulfate, 1 part of polyaspartic acid, 4 parts of vermiculite powder, 15 parts of polyurethane resin, 45 parts of humic acid.

Embodiment 2

[0014] A slow-release fertilizer, consisting of the following raw materials in parts by weight: 20 parts of urea, 22 parts of superphosphate, 15 parts of potassium sulfate, 0.03 part of sodium octaborate tetrahydrate, 0.05 part of zinc sulfate, 0.1 part of iron sulfate, ammonium molybdate 0.02 parts, 0.3 parts of magnesium sulfate, 1 part of polyaspartic acid, 3 parts of vermiculite powder, 10 parts of polyurethane resin, 35 parts of humic acid.

Embodiment 3

[0016] A slow-release fertilizer, consisting of the following raw materials in parts by weight: 30 parts of urea, 20 parts of superphosphate, 16 parts of potassium sulfate, 0.05 part of sodium octaborate tetrahydrate, 0.1 part of zinc sulfate, 0.2 part of iron sulfate, ammonium molybdate 0.01 parts, 0.5 parts of magnesium sulfate, 2 parts of polyaspartic acid, 5 parts of vermiculite powder, 12 parts of polyurethane resin, 40 parts of humic acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com