Method for realizing dehydration of 2-picoline through coupling of extraction and rectification

A coupling technology of methyl pyridine and rectification, applied in the direction of organic chemistry, etc., can solve the problems such as the inability to recycle the lye, the inability to discharge the alkali water directly, and the limited ability of benzene to carry water, and achieve high product recovery rate and low production cost. , the effect of high volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

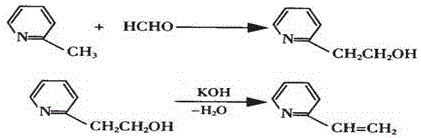

Problems solved by technology

Method used

Image

Examples

Embodiment 1

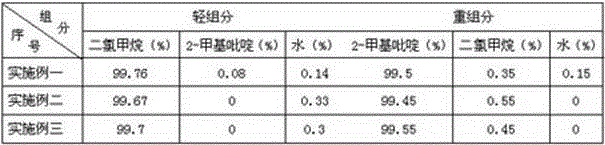

[0024] This example was carried out in batch mode. First weigh 100 mass parts of 2-picoline and mix 150 mass parts of water as the 2-picoline solution to be dehydrated, then add 800 mass parts of dichloromethane to prepare a mixed solution, and place the mixed solution in In the separatory funnel, seal it with a glass stopper, shake the separatory funnel to mix the materials evenly, then let it stand for 2 hours, you can see obvious stratification, wherein the upper layer is the water phase, and the lower layer contains 2-picoline and The organic phase of dichloromethane was separated to obtain an aqueous phase and an organic phase. It was found by measurement that the aqueous phase was 170 parts by mass, and the organic phase was 880 parts by mass, and the first extraction was completed.

[0025] By testing, the mass percentage of 2-picoline in the water phase is 11.1%. The water phase after the first extraction is mixed with 190 parts by mass of dichloromethane, and dichloro...

Embodiment 2

[0030] The difference between this example and Example 1 is that both the sample and the dichloromethane are fed continuously. Wherein in the mixed solution of 2-picoline and water, the mass percentage composition of 2-picoline is 50%, the feed flow rate is 200kg / h, and the feed flow rate of extractant dichloromethane is 1000kg / h , After the two are mixed evenly by the mixer, they enter the phase separator for static phase separation, ensuring that the residence time of the material in the phase separator is 55min, and the aqueous phase and the organic phase can be continuously extracted. The produced water phase flow rate is 106.4kg / h, and the organic phase flow rate is 1093.6kg / h.

[0031] The aqueous phase obtained by phase separation for the first time is mixed with methylene chloride at a flow rate of 100kg / h, and then phase-separated, the aqueous phase flow rate is 99.8 kg / h, and its composition is measured to know that the mass fraction of water is 99.5%. The mass frac...

Embodiment 3

[0034] The difference between this embodiment and Example two is: in the mixed solution of 2-picoline and water, the mass percentage of 2-picoline is 10%, the feed flow rate is 200kg / h, and the extraction agent The feed flow rate of dichloromethane is 160kg / h. After the two are mixed evenly by the mixer, they enter the phase separator for phase separation, ensuring that the residence time of the material in the phase separator is 30min, and the aqueous phase and organic phase can be continuously extracted. Mutually. The produced aqueous phase flow rate is 185.3 kg / h, and the organic phase flow rate is 174.7 kg / h.

[0035] The water phase obtained by phase separation for the first time is mixed with methylene chloride at a flow rate of 50kg / h, and then separated again, the flow rate of the water phase is 180.6 kg / h, and the mass fraction of water obtained by measuring its composition is 99.6%. The mass fraction of 2-picoline is 0.34%, and the mass fraction of dichloromethane i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com