Fluorocarbon elastic emulsion and preparation method thereof

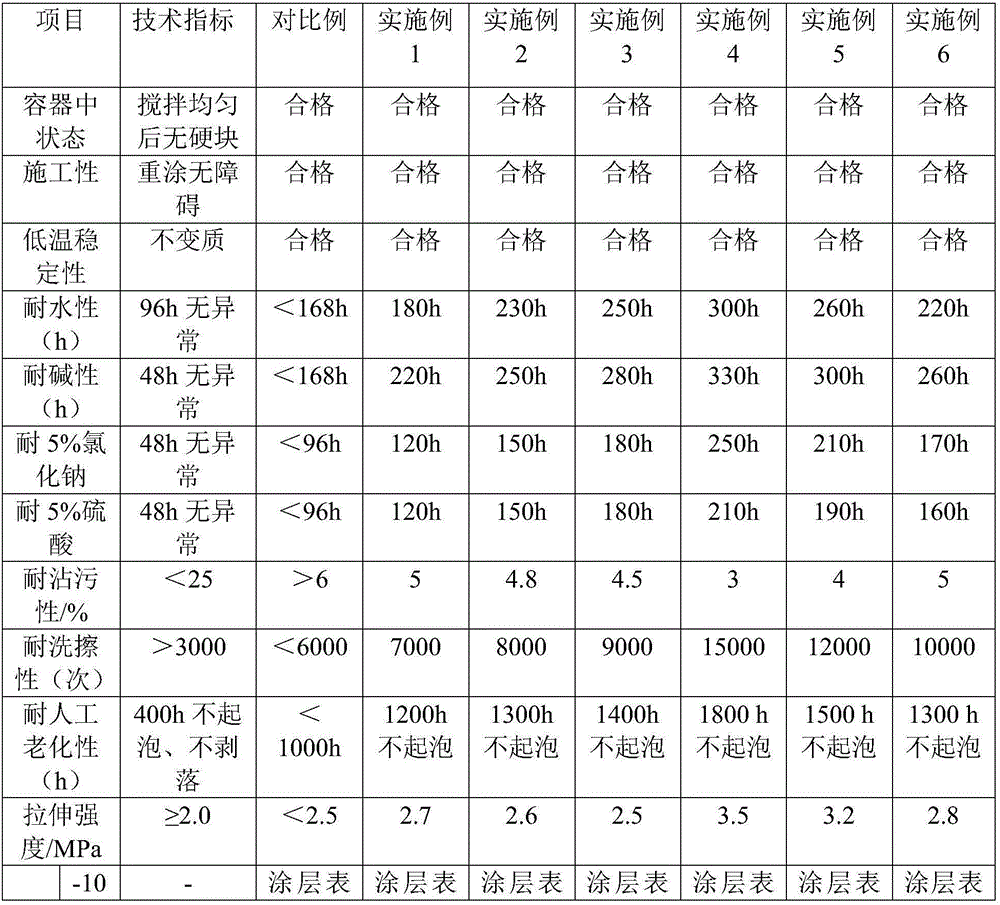

An elastic emulsion and fluorocarbon technology, applied in the field of emulsion, can solve the problems of low glass transition temperature, weather resistance, stain resistance and artificial aging resistance, etc., achieve high weather resistance, improve adhesion, and improve wetting Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Fluorocarbon elastic emulsion, by weight percentage, butyl acrylate 24%, hexafluorobutyl methacrylate 8.5%, methyl methacrylate 8%, methacrylic acid 1.5%, benzophenone 0.5%, PAM1000.3 %, Ethylene Glycol Dimethacrylate 0.4%, Sodium Lauryl Sulfate 1.2%, Allyl Polyoxyethylene Ether Ammonium Sulfate 0.3%, Phosphate Ester Polymerizable Emulsifier 0.5%, Potassium Persulfate 1.8%, Water 52.1%, tert-butyl hydroperoxide 0.2%, L-ascorbic acid 0.2%, ammonia 0.5%.

[0031] After taking the material in the manner of the above-mentioned embodiments, it can be prepared according to the traditional process, and a better choice is to prepare according to the following preparation method:

[0032] (1) Preparation of emulsion: take 1 / 2 of water and 1 / 2 of emulsifier, add fluorine-containing monomer, butyl acrylate, methyl methacrylate, acrylic acid, vinyl alkoxy phosphate under stirring , Ethylene glycol dimethacrylate and benzophenone are emulsified, the emulsification time is 18min, an...

Embodiment 2

[0040]Fluorocarbon elastic emulsion, by weight percentage, butyl acrylate 23.5%, dodecafluoroheptyl methacrylate 12%, methyl methacrylate 5%, acrylic acid 2%, benzophenone 0.5%, PAM1000.3% , Ethylene Glycol Dimethacrylate 0.2%, Sodium Lauryl Sulfate 1.2%, Ammonium Allyl Polyoxyethylene Ether Sulfate 0.3%, Phosphate Ester Polymerizable Emulsifier 0.5%, Ammonium Persulfate 1.5%, Water 52.6 %, tert-butyl hydroperoxide 0.1%, L-ascorbic acid 0.1%, ammonia water 0.2%.

[0041] After taking the material in the manner of the above-mentioned embodiments, it can be prepared according to the traditional process, and a more optimal choice is to prepare according to the following preparation method:

[0042] (1) Preparation of emulsion: take 1 / 3 of water and 1 / 3 of emulsifier, add fluorine-containing monomer, butyl acrylate, methyl methacrylate, acrylic acid, vinyl alkoxy phosphate under stirring , ethylene glycol dimethacrylate and benzophenone for emulsification, the emulsification time...

Embodiment 3

[0050] Fluorocarbon elastic emulsion, by weight percentage, butyl acrylate 20%, hexafluorobutyl methacrylate 10%, dodecafluoroheptyl methacrylate 5%, methyl methacrylate 5.5%, methacrylic acid 1.5% , Benzophenone 0.8%, PAM100 0.3%, Ethylene Glycol Dimethacrylate 0.4%, Sodium Lauryl Sulfate 1.2%, Allyl Polyoxyethylene Ammonium Sulfate 0.3%, Phosphate Ester Polymerizable Emulsifier 0.5%, ammonium persulfate 1.5%, water 52.5%, tert-butyl hydroperoxide 0.05%, L-ascorbic acid 0.05%, ammonia water 0.4%.

[0051] After taking the material in the manner of the above-mentioned embodiments, it can be prepared according to the traditional process, and a more optimal choice is to prepare according to the following preparation method:

[0052] (1) Preparation of emulsion: Take 2 / 5 of water and 2 / 5 of emulsifier, add fluorine-containing monomer, butyl acrylate, methyl methacrylate, acrylic acid, vinyl alkoxy phosphate under stirring , ethylene glycol dimethacrylate and benzophenone for emu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com