Oil removal agent for thickened oil thermal recovery sewage and preparation method thereof

A technology of heavy oil thermal recovery and degreasing agent, which is applied in water/sewage treatment, mining wastewater treatment, chemical instruments and methods, etc., can solve the problem of unsatisfactory degreasing effect, and achieve easy acquisition, transportation, storage and synthesis process Simple, efficient degreasing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Degreaser A 1 and its preparation method

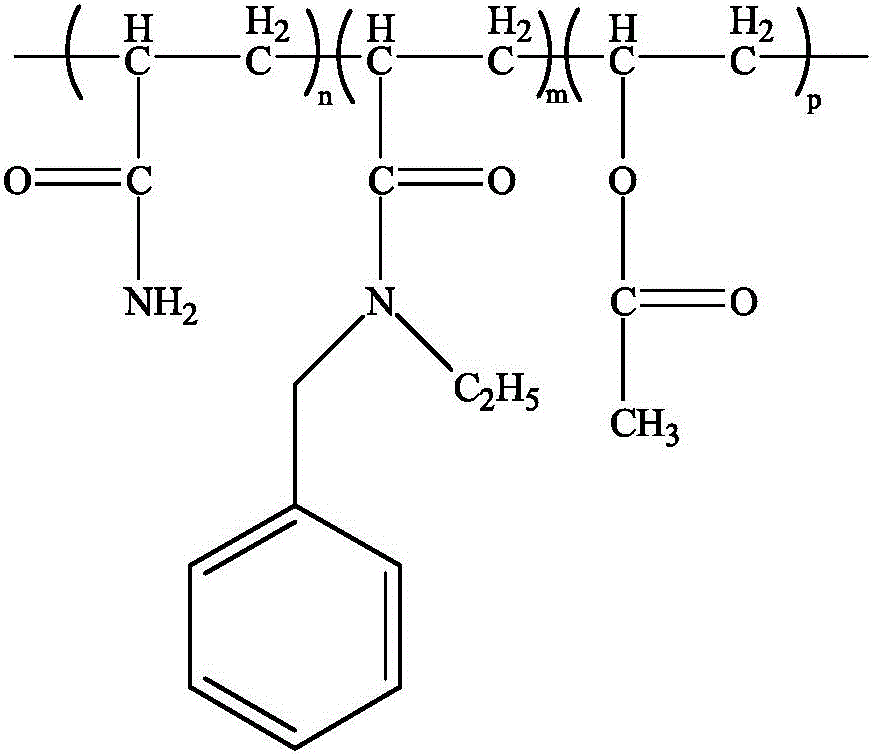

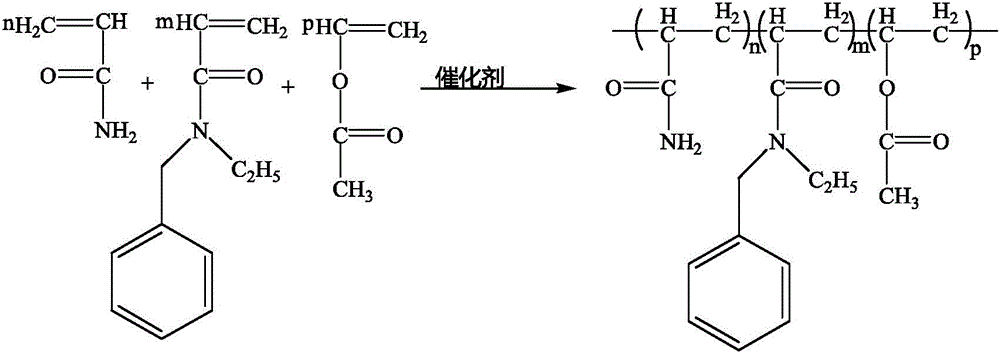

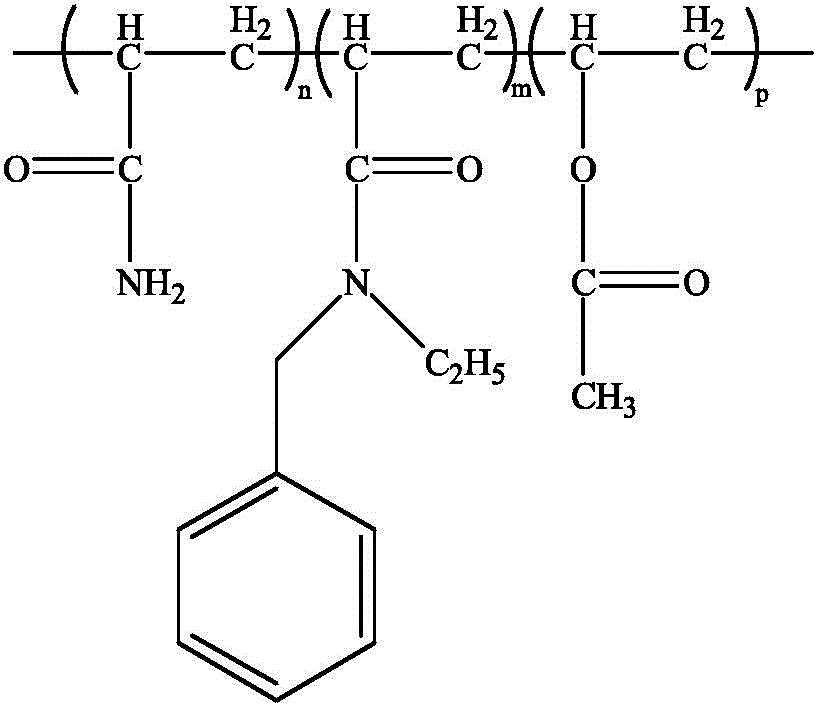

[0030] (1) Degreaser A 1 The composition, components and molecular weight are as follows:

[0031] Degreaser A 1 It is prepared from acrylamide, N-benzyl-N-ethylacrylamide and vinyl acetate in a molar ratio of 1:0.5:0.1 through free radical micellar polymerization, with an average molecular weight of 8000.

[0032] (2) Degreaser A 1 The preparation method is as follows:

[0033] ①Add 355.4g of deionized water and 0.5mol of N-benzyl-N-ethylacrylamide into a three-necked flask equipped with a thermometer and a stirring rod, raise the temperature to 30°C at a stirring rate of 200rpm, and keep the temperature constant for 20min;

[0034] ② Add 1 mol of acrylamide to the above-mentioned three-necked flask, raise the temperature to 45°C, add 0.36g of sodium lauryl sulfate, stir for 36min at a stirring rate of 500rpm, after the stirring time is over, the temperature rises to 60°C, Constant temperature 25min obtains...

Embodiment 2

[0037] Embodiment 2: Degreaser A 2 and its preparation method

[0038] (1) Degreaser A 2 The composition, components and molecular weight are as follows:

[0039] Degreaser A 2 It is prepared from acrylamide, N-benzyl-N-ethylacrylamide and vinyl acetate in a molar ratio of 1:1.5:2 through free radical micellar polymerization, with an average molecular weight of 25,000.

[0040] (2) Degreaser A 2 The preparation method is as follows:

[0041] ①Add 710.8g of deionized water and 1.5mol of N-benzyl-N-ethylacrylamide into a three-necked flask equipped with a thermometer and a stirring rod, raise the temperature to 35°C at a stirring rate of 260rpm, and keep the temperature constant for 25min;

[0042] ② Add 1 mol of acrylamide to the above-mentioned three-necked flask, raise the temperature to 48°C, add 0.71g of sodium dodecylsulfonate, and stir for 30 minutes at a stirring rate of 520rpm. After the stirring time is over, the temperature rises to 63°C , constant temperature f...

Embodiment 3

[0045] Embodiment 3: Degreaser A 3 and its preparation method

[0046] (1) Degreaser A 3 The composition, components and molecular weight are as follows:

[0047] Degreaser A 3 It is prepared from acrylamide, N-benzyl-N-ethylacrylamide and vinyl acetate in a molar ratio of 1:3:2.5 by free radical micellar polymerization, and has an average molecular weight of 48,000.

[0048] (2) Degreaser A 3 The preparation method is as follows:

[0049] ①Add 1066.2g of deionized water and 3mol of N-benzyl-N-ethylacrylamide into a three-necked flask equipped with a thermometer and a stirring rod, raise the temperature to 40°C at a stirring rate of 300rpm, and keep the temperature at a constant temperature for 30min;

[0050] ② Add 1 mol of acrylamide to the above-mentioned three-necked flask, raise the temperature to 50°C, add 1.42g of sodium dodecylsulfonate, and stir for 40min at a stirring rate of 550rpm. After the stirring time is over, the temperature rises to 65°C , keep the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com