A kind of transparent fireproof coating for building timber

A fire retardant coating and wood technology, applied in fire retardant coatings, antifouling/underwater coatings, coatings, etc., can solve the problems of poor coating flexibility, weather resistance and antibacterial properties, aggravating coating film cracking, and coating film cracking. , to shorten the surface drying time, improve the rigidity, and improve the weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

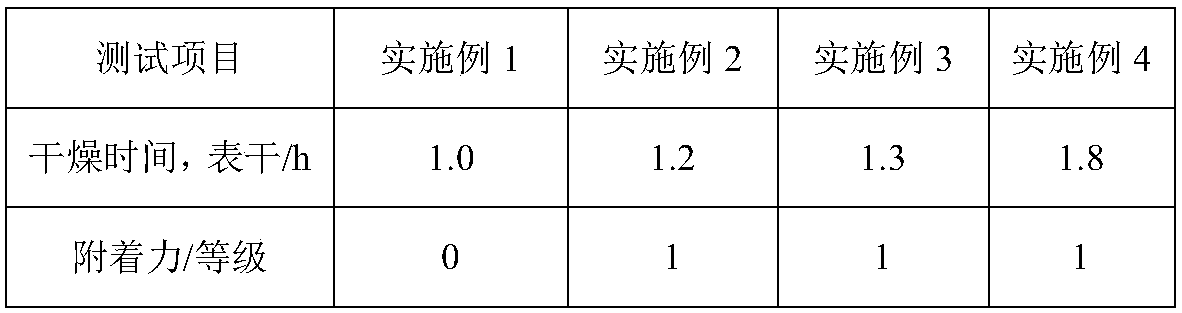

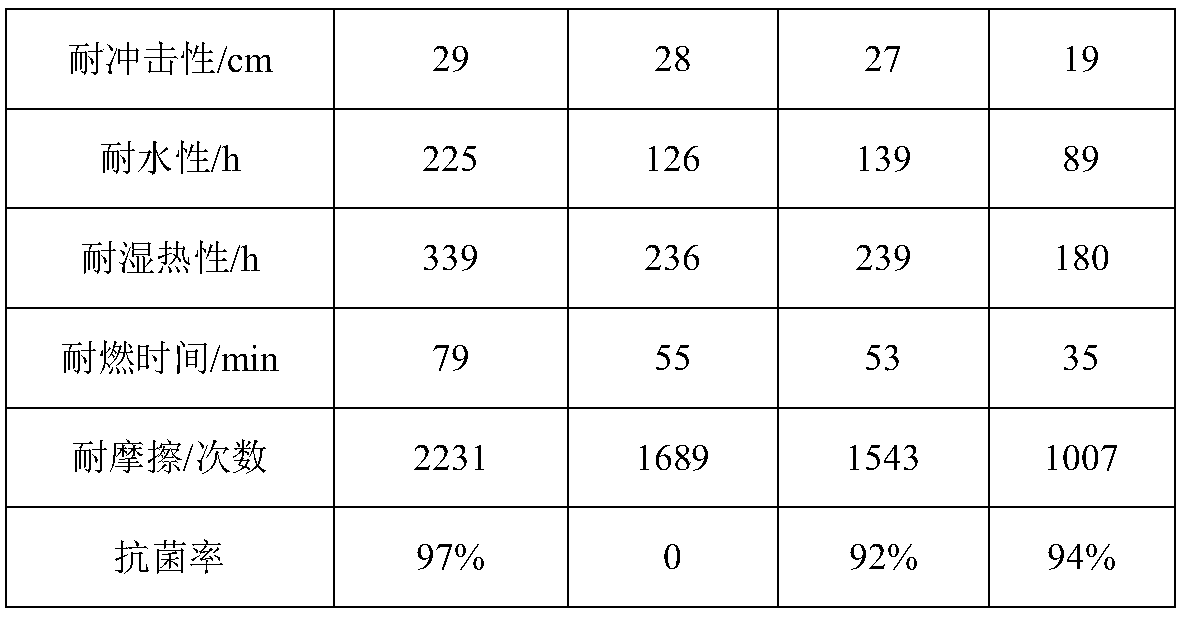

Embodiment 1

[0038] (1) 65 grams of water glass, 35 grams of modified calcium carbonate, 2 grams of polyoxyethylene polyoxypropanolamine ether and 26 grams of sulfonated polyetheramine-polybenzimidazole-hyperbranched polypyrrole terpolymer After mixing evenly with a mixer, add it to 20 grams of deionized water, which is component A, and set aside;

[0039] (2) 70 grams of ethyl orthosilicate, 2,2', 2", 2"'-[1,2-bidimethylene tetrakis (4,1-phenylene methylene oxide)] tetracyclic 20 grams of oxyethane, 8 grams of 6-bromo-1,2-epoxyhexane and 9 grams of ethanol are mixed evenly with a mixer, which is the B component, which is ready for use;

[0040] (3) After mixing 35 grams of modified nano-silica, 7 grams of ethylene glycol, 8 grams of KH-550 and 3 grams of N,N'-carbonyldiimidazole with a mixer, add 15 grams of dimethyl methylene Among the sulfones, it is the C component, which is ready for use;

[0041] (4) A, B, and C are mixed uniformly to obtain a kind of wood structure transparent firep...

Embodiment 2

[0066] (1) 65 grams of water glass, 35 grams of calcium carbonate with an average particle size of 2000 meshes, 2 grams of polyoxyethylene polyoxypropanolamine ether and sulfonated polyetheramine-polybenzimidazole-hyperbranched polypyrrole terpolymer After mixing 26 grams of the compound evenly with a mixer, add it to 20 grams of deionized water, which is the A component, and stand-by;

[0067] (2) 70 grams of ethyl orthosilicate, 2,2', 2", 2"'-[1,2-bidimethylene tetrakis (4,1-phenylene methylene oxide)] tetracyclic 20 grams of oxyethane, 8 grams of 6-bromo-1,2-epoxyhexane and 9 grams of ethanol are mixed evenly with a mixer, which is the B component, which is ready for use;

[0068] (3) After mixing 35 grams of modified nano-silica, 7 grams of ethylene glycol, 8 grams of KH-550 and 3 grams of N,N'-carbonyldiimidazole with a mixer, add 15 grams of dimethyl methylene Among the sulfones, it is the C component, which is ready for use;

[0069] (4) A, B, and C are mixed uniforml...

Embodiment 3

[0087] (1) 65 grams of water glass, 35 grams of modified calcium carbonate, 2 grams of polyoxyethylene polyoxypropanolamine ether and 26 grams of sulfonated polyetheramine-polybenzimidazole-hyperbranched polypyrrole terpolymer After mixing evenly with a mixer, add it to 20 grams of deionized water, which is component A, and set aside;

[0088] (2) 70 grams of ethyl orthosilicate, 2,2', 2", 2"'-[1,2-bidimethylene tetrakis (4,1-phenylene methylene oxide)] tetracyclic 20 grams of oxyethane, 8 grams of 6-bromo-1,2-epoxyhexane and 9 grams of ethanol are mixed evenly with a mixer, which is the B component, which is ready for use;

[0089] (3) After mixing 35 grams of silicon dioxide with an average particle size of 300 nanometers, 7 grams of ethylene glycol, 8 grams of KH-550 and 3 grams of N,N'-carbonyldiimidazole with a mixer, add 15 grams of diimidazole In methyl sulfoxide, it is component C, ready for use;

[0090] (4) A, B, and C are mixed uniformly to obtain a kind of wood s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com