Method for catalyzing hydrolysis of lignocellulose by heteropoly acid

A technology of lignocellulose and heteropolyacids, applied in sugar production, xylose production, sugar production, etc., can solve problems that need to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

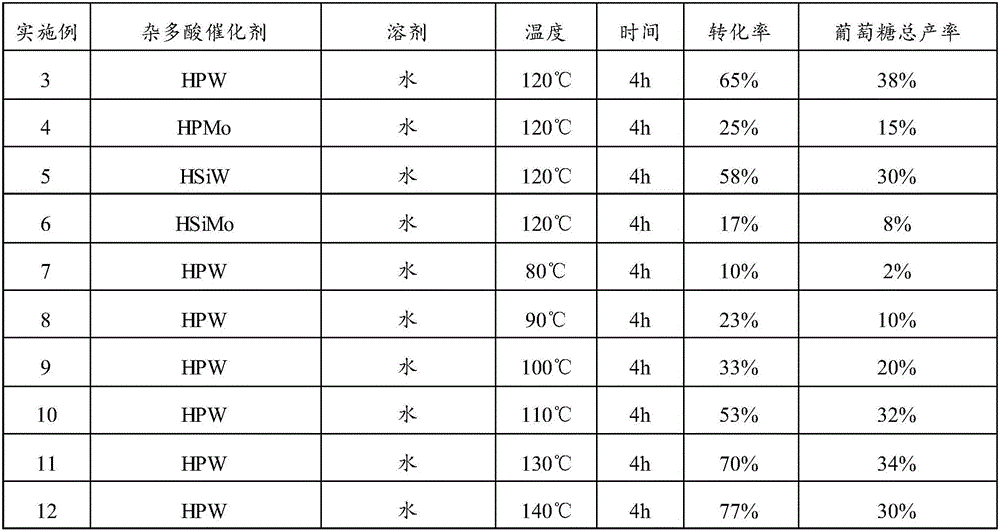

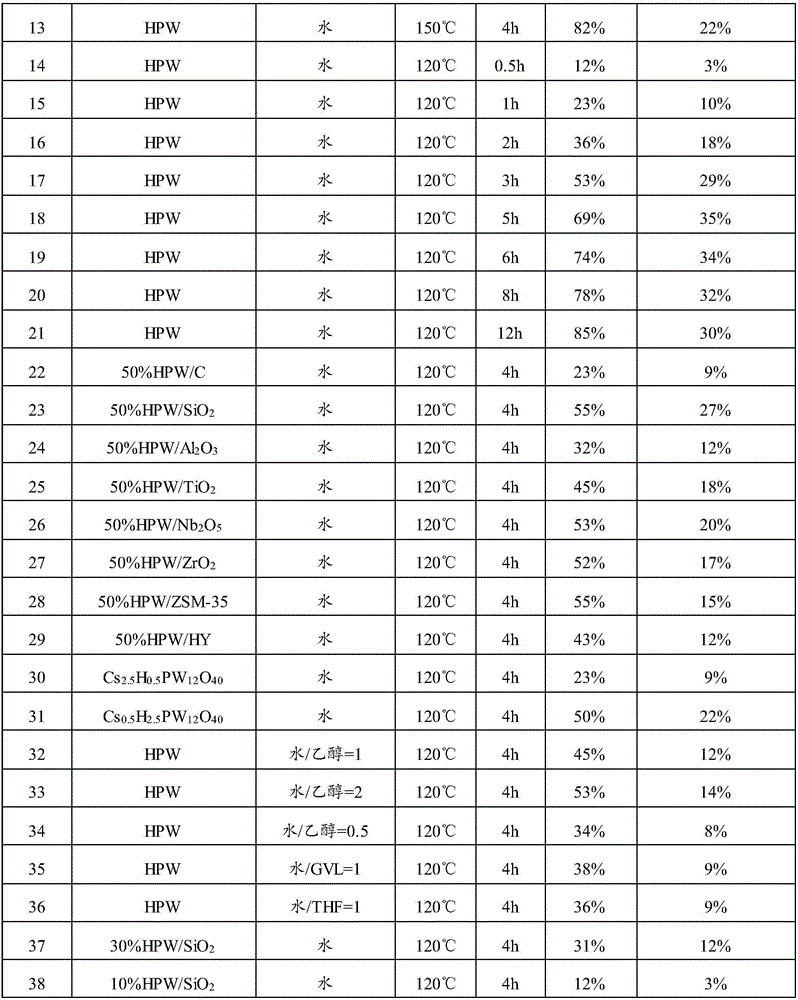

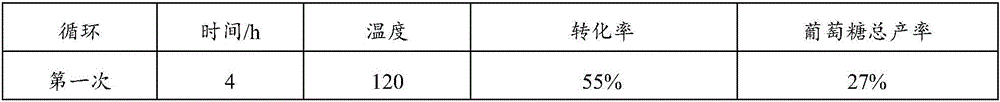

Examples

preparation example Construction

[0027] The preparation method of the supported heteropolyacid catalyst is a preparation method well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably prepared according to the following method: the carrier is immersed in the solution containing the active ingredient, and the The solvent is dried to obtain a loaded heteropolyacid catalyst. The solution containing the active ingredient is preferably obtained by dissolving the active ingredient in a volatile solvent; the volatile solvent is preferably an alcohol solvent, more preferably ethanol; in the present invention, it is preferred to first mix the carrier with the volatile solvent, and then add The solution containing the active ingredient is then preferably stirred at room temperature for 1 to 10 hours, more preferably at room temperature for 3 to 10 hours, then preferably at room temperature for 6 to 10 hours, most preferably at room temperature for 8 hours, t...

Embodiment 1

[0038] Preparation of heteropolyacids:

[0039] The preparation method of the heteropolyacid salt is a co-precipitation method. with Cs x h y PW 12 o 40 Take the catalyst as an example. Dissolve 0.5g of phosphotungstic acid in 10mL of water in a flask, then slowly add 5mL of aqueous solution containing the required amount of cesium carbonate to the solution under stirring, stir at room temperature for 6h, and then use a Buchner funnel to Extract and wash with water for 3 to 5 times, and dry under vacuum at 70°C overnight.

[0040] The preparation method of the heteropolyacid salt catalyst is not particularly limited in the present invention, and is a method well known to those skilled in the art.

Embodiment 2

[0042] Preparation of supported heteropolyacid catalyst:

[0043] The preparation method of HPW supported catalyst is impregnation method. With 50%HPW / SiO 2 As an example, dissolve 0.5g of phosphotungstic acid (HPW) in 10mL of ethanol, then slowly add the solution to a volume containing 20mL of ethanol and 1g of SiO 2 in a flask, stirred at room temperature for 8 hours, spin-dried, and dried overnight at 120°C to obtain a supported heteropolyacid catalyst.

[0044] The preparation method of the HPW-supported catalyst system is not particularly limited in the present invention, and is a method well known to those skilled in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com