Micro drill provided with transition metal boride coating and used for PCB and preparation method of micro drill

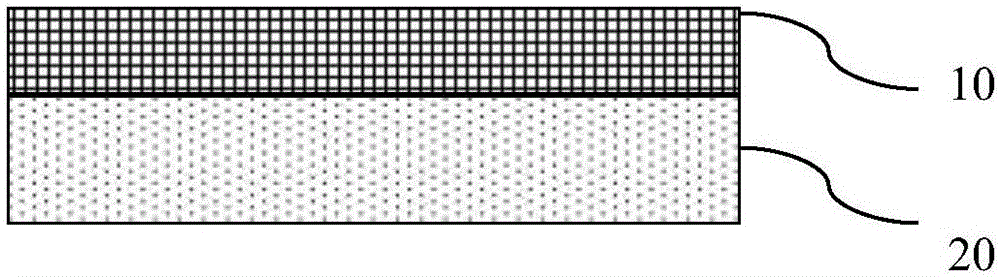

A transition metal, boride technology, applied in metal material coating process, coating, twist drill and other directions, can solve the problems of high residual stress of PCB hard coating, easy peeling of film layer, low bonding strength of film base, etc. To achieve the effect of improving the bonding strength of the film base, not easy to peel off, and strong bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

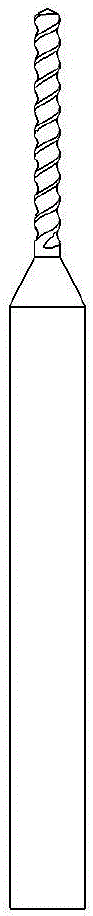

[0056] A preparation method for a PCB micro-drill with a transition metal boride coating, comprising the following steps:

[0057] (1) Pretreatment: Use the YG6 (WC-6% Co) cemented carbide micro-drill sold in the domestic market as the substrate, first put the micro-drill into the acetone solution for ultrasonic cleaning for 10-20 minutes, and then put it into the alcohol solution Ultrasonic cleaning for 10 to 20 minutes, then dry the surface with dry nitrogen, and then put the blade in a vacuum drying oven to dry;

[0058] (2) Furnace loading: open the vacuum chamber door of the sputter coating equipment, and clamp the micro drill on the fixture;

[0059] (3) Vacuuming: close the door of the vacuum chamber, open the water cooler to connect the magnetron target, molecular pump, and the water circuit of the vacuum chamber, turn on the main power supply of the air compressor and coating machine, and then turn on the mechanical pump and the fore-stage valve for molecular Pump va...

Embodiment 2

[0072] A preparation method for a PCB micro-drill with a transition metal boride coating, comprising the following steps:

[0073] (1) Pre-treatment: Use the YG8 (WC-8% Co) cemented carbide micro-drill sold in the domestic market as the substrate, first put the micro-drill into the acetone solution for ultrasonic cleaning for 10 minutes, and then put it into the alcohol solution for further cleaning. Ultrasonic cleaning for 15 minutes, then dry the surface with dry nitrogen, and then put the blade in a vacuum drying oven to dry;

[0074] (2) Furnace loading: open the vacuum chamber door of the sputter coating equipment, and clamp the micro drill on the fixture;

[0075] (3) Vacuuming: close the door of the vacuum chamber, open the water cooler to connect the magnetron target, molecular pump, and the water circuit of the vacuum chamber, turn on the main power supply of the air compressor and coating machine, and then turn on the mechanical pump and the fore-stage valve for molecu...

Embodiment 3

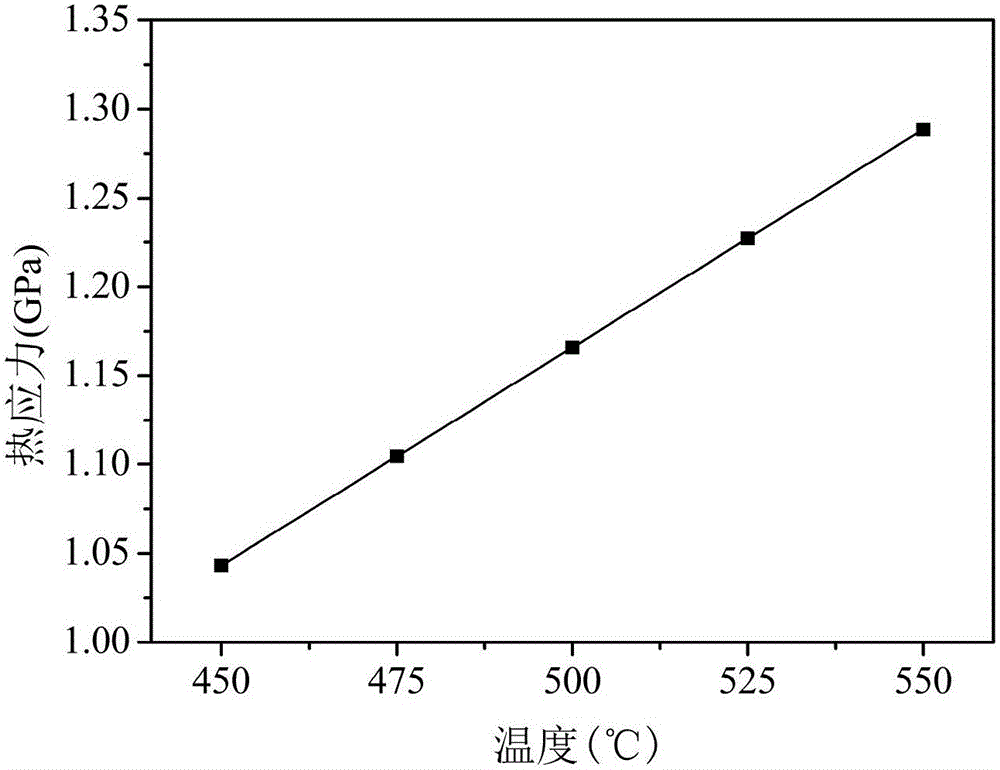

[0082] Using YT15 carbide micro drill, using CrB 2 Depositing CrB on micro-drills as a sputtering target 2 coating. Ion source working current 30A, working voltage 75V, sputtering target power 8W / cm 2 , the negative bias voltage is 255V, the deposition temperature is 550°C, and the coating thickness is 2.5μm.

[0083] Example 3

[0084] A preparation method for a PCB micro-drill with a transition metal boride coating, comprising the following steps:

[0085] (1) Pretreatment: Using the YT15 cemented carbide micro-drill bit sold in the domestic market as the substrate, first put the micro-drill into acetone solution for ultrasonic cleaning for 10 minutes, then put it into alcohol solution for ultrasonic cleaning for 15 minutes, and then dry it with Nitrogen blows the surface dry, and then puts the blade in a vacuum drying oven to dry;

[0086] (2) Furnace loading: open the vacuum chamber door of the sputter coating equipment, and clamp the micro drill on the fixture;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com