Graphene-coated aluminium foil current collector and preparation method thereof

A technology of graphene and current collectors, which is applied in the field of high-performance graphene-coated aluminum foil current collectors and its preparation, can solve the problems of complex synthesis process, limited dispersion effect, and influence on material conductivity, and achieve simple and controllable preparation process, Improved rate performance and improved cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

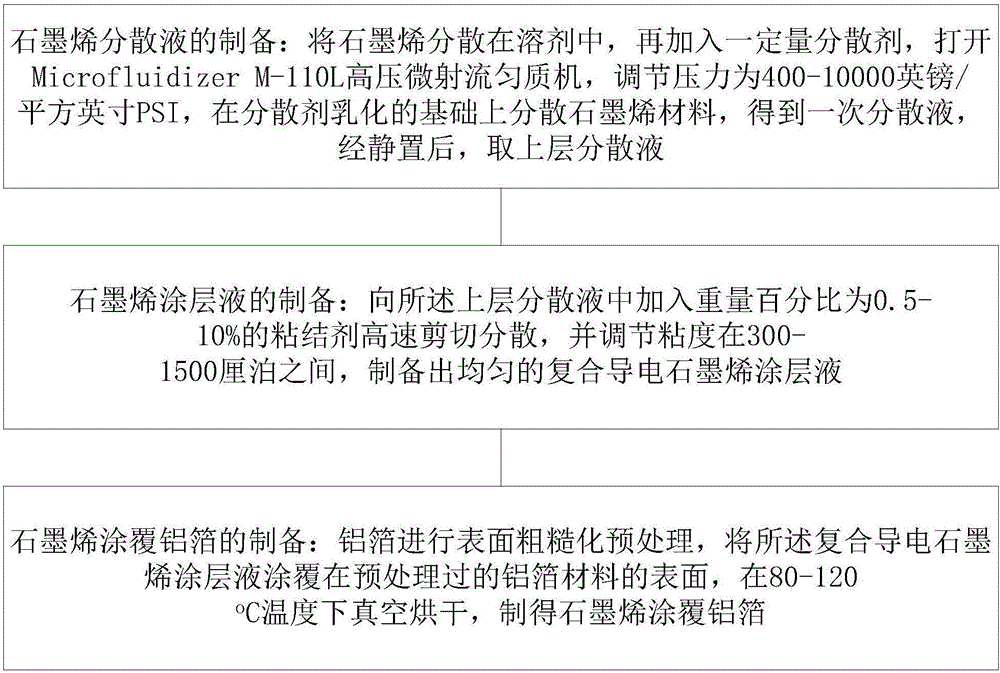

[0027] Please refer to figure 1 , the embodiment of the present invention provides a method for preparing a graphene-coated aluminum foil current collector, comprising the following steps:

[0028] (1) Preparation of graphene dispersion: disperse graphene in solvent, then add a certain amount of dispersant, open Microfluidizer M-110L high-pressure micro-jet homogenizer, adjust pressure to be 400-10000 pounds per square inch PSI, in Disperse the graphene material on the basis of the emulsification of the dispersant to obtain a primary dispersion, and after standing still, take the upper dispersion;

[0029] (2) Preparation of graphene coating liquid: adding a weight percentage of 0.5-10% binder into the upper dispersion liquid for high-speed shear dispersion, and adjusting the viscosity between 300-1500 centipoise to prepare a uniform Composite conductive graphene coating solution;

[0030] (3) Preparation of graphene-coated aluminum foil: the aluminum foil is subjected to su...

Embodiment 1

[0036] Stir 5wt% graphene and 2wt% dispersant PVP into the solvent NMP, turn on the Microfluidizer M-110L high-pressure micro-jet homogenizer, adjust the pressure to 8000 pounds per square inch PSI, and disperse graphene on the basis of dispersant emulsification materials to obtain a primary dispersion. After standing still, take the upper layer dispersion liquid. Then add 2wt% binder PVDF high-speed shear dispersion to the dispersion, adjust the viscosity at 300-1500 centipoise to obtain a conductive graphene coating liquid; then, the aluminum foil is first roughened in sodium hydroxide or oxalic acid treated and dried. Coat the dispersed graphene coating solution on one or both sides of the pretreated aluminum foil material, and then dry it in a vacuum at 80-120°C for 6 hours to obtain a graphene-coated aluminum foil product. The coating is around 3 microns.

Embodiment 2

[0038] Stir 3wt% graphene and 5wt% dispersant PVA into the water, turn on the Microfluidizer M-110L high-pressure micro-jet homogenizer, adjust the pressure to 12,000 pounds per square inch PSI, and disperse the graphene material on the basis of emulsification of the dispersant, A dispersion was obtained. After standing still, take the upper layer dispersion liquid. Then add 2wt% binder CMC high-speed shear dispersion to the dispersion, adjust the viscosity at 600-2000 centipoise, and obtain the conductive graphene coating liquid; then, the aluminum foil is first roughened in sodium hydroxide or oxalic acid treated and dried. Coat the dispersed graphene coating solution on one or both sides of the pretreated aluminum foil material, and then dry it under vacuum at 120°C for 6 hours to obtain a graphene-coated aluminum foil product. The graphene coating layer Around 20 microns.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com