Platinum-based nanoparticle coating and tin dioxide covering carbon nanotube and preparation method thereof

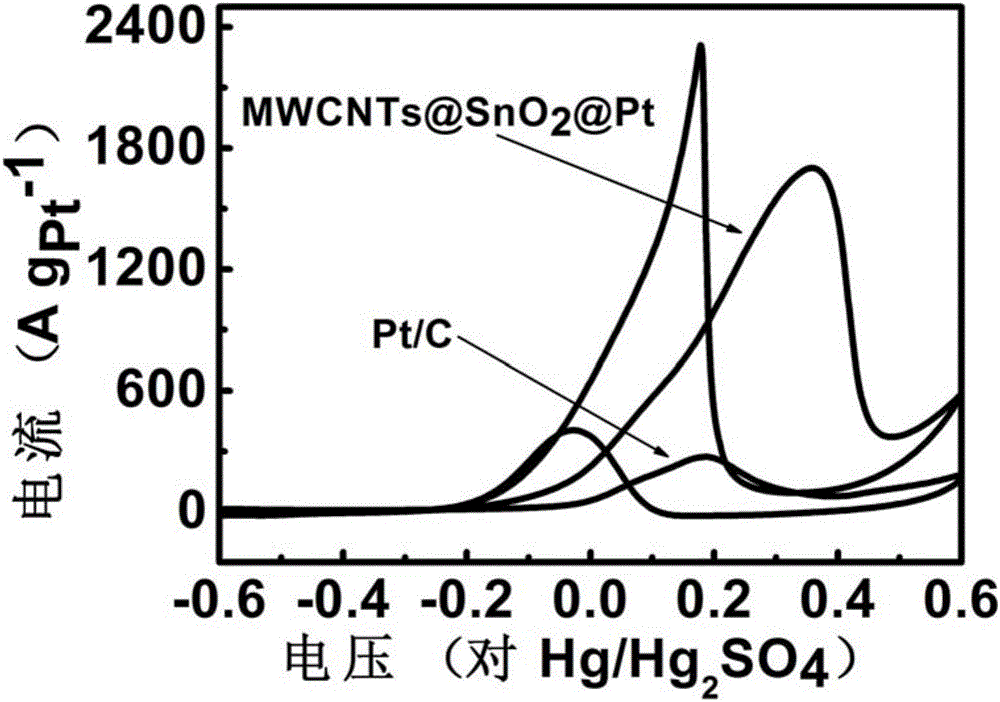

A technology of carbon nanotubes and tin dioxide, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of unsatisfactory stability and anti-poisoning ability, so as to improve the ability of anti-carbon monoxide poisoning, improve the utilization rate, and improve the anti-poisoning ability. The effect of the poison ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

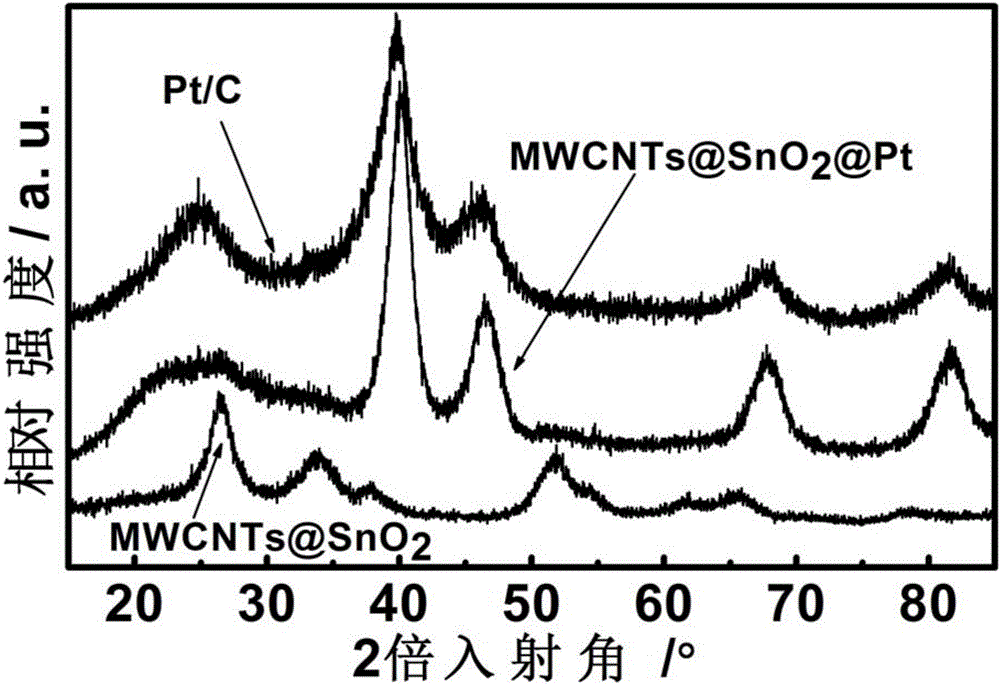

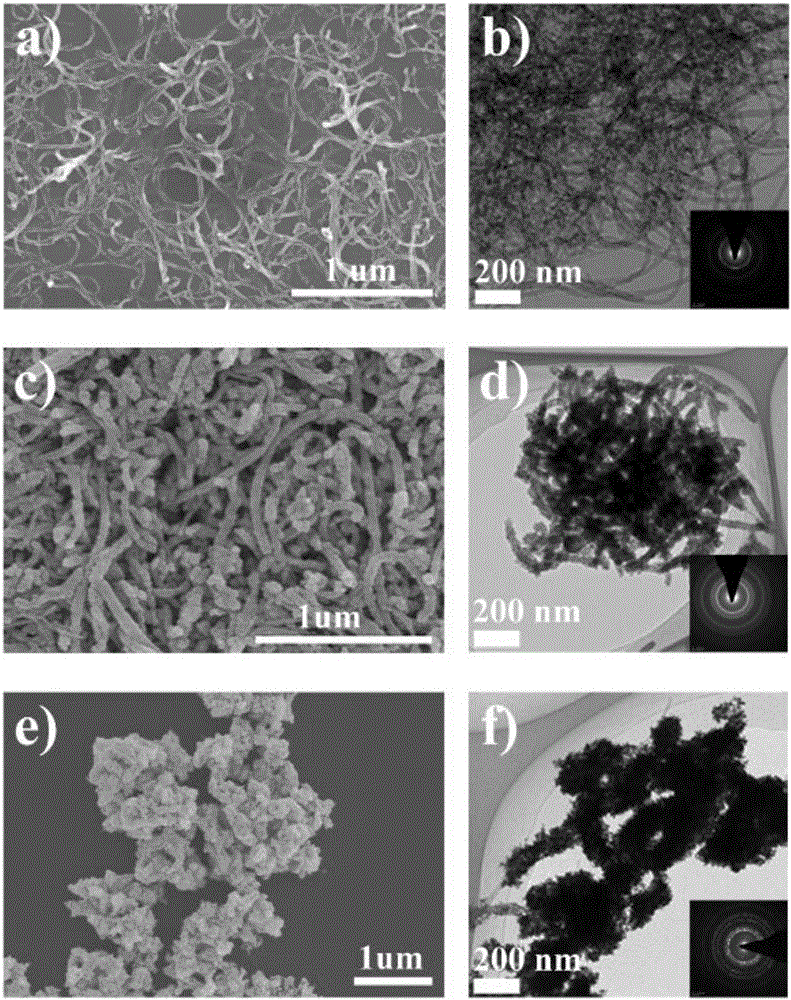

[0048] Example 1: Platinum-based nanoparticles coated tin dioxide-covered carbon nanotubes (MWCNTs@SnO 2 @Pt, preparation of 86% by weight platinum in platinum, tin dioxide and multi-walled carbon nanotubes)

[0049] (1) Dispersing multi-walled carbon nanotubes (MWCNTs) in concentrated nitric acid, reacting in an oil bath at 140 degrees Celsius for more than 10 hours, cooling and filtering, drying and grinding to obtain functionalized multi-walled carbon nanotubes for use;

[0050] (2) SnCl 2 2H 2 O, urea, the functionalized multi-walled carbon nanotubes of step (1) and water are stirred at room temperature for more than 30 minutes to fully disperse them, and continue to sonicate to obtain a highly dispersed solution-like mixture. Then reflux and stir in an oil bath at 90 degrees centigrade for 10 hours, then cool and filter. A material in which carbon nanotubes are covered with tin dioxide is obtained.

[0051] (3) put H 2 PtCl 6 ·6H 2 O and step (2) gained tin dioxide...

Embodiment 2

[0064] Example 2: Platinum-copper core-shell nanoparticles coated carbon nanotubes covered with tin dioxide (MWCNTs@SnO 2 Preparation of @Pt-Cu@Pt)

[0065] (1) H 2 PtCl 6 ·6H 2 O, CuSO 4 ·5H 2 O, multi-walled carbon nanotubes covered with tin dioxide and ethylene glycol were stirred at room temperature for 30 minutes to fully disperse them. The molar ratio of Pt and Cu in the mixed solution is 1:3;

[0066] (2) the mixed solution obtained in step (1) is alternately used to stir and sonicate, and then adjust its pH value to 10 with sodium hydroxide ethylene glycol solution;

[0067] (3) Continue to alternately use ultrasound and stirring the mixed solution obtained in step (2) until a solution-like dispersion is formed;

[0068] (4) Put the mixed solution obtained in step (3) into a microwave reactor, pass through nitrogen to deoxygenate, simultaneously pass on condensed water, and stir for 30 minutes;

[0069] (5) microwave the solution obtained in step (4) for more tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com