Acoustic absorbing material, preparation method thereof and loudspeaker applying acoustic absorbing material

A technology of sound-absorbing materials and molecular sieves, applied in the field of sound-absorbing materials, to achieve the effects of improving low-frequency acoustic performance, increasing volume, and improving low-frequency response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

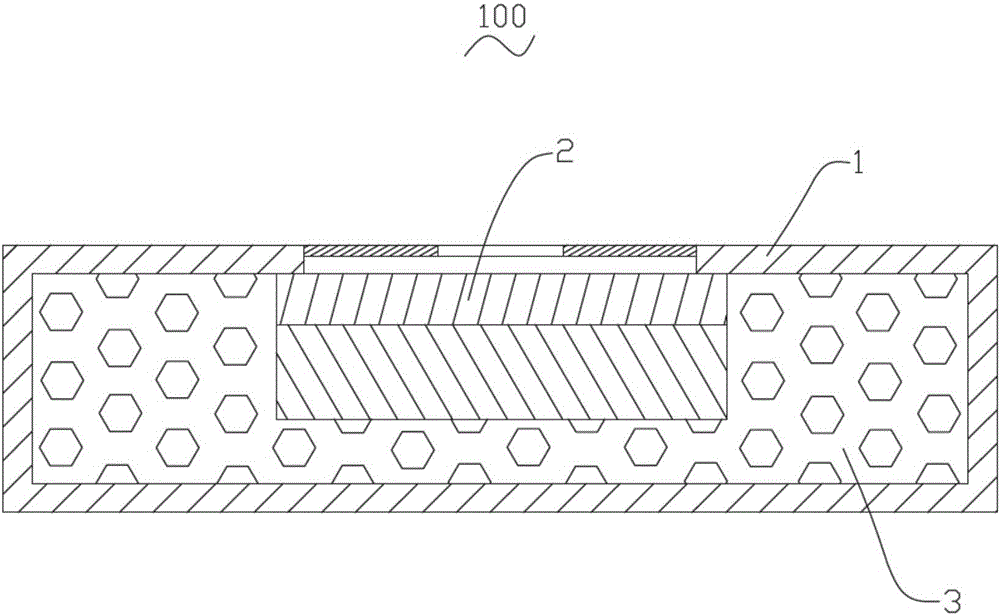

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method for the sound-absorbing material in the speaker, which includes the following steps:

[0047] Step S1, using silicon source, M source, alkali source, templating agent and hydration to synthesize a MEL structure molecular sieve with a molar ratio of silicon element to other element M of at least 80;

[0048] Among them, the silicon source includes tetraethyl orthosilicate, silica sol and sodium silicate; the M source is determined according to the skeleton of the molecular sieve with MEL structure; the alkali source includes sodium hydroxide, potassium hydroxide and lithium hydroxide; the template is tetrabutyl quaternary Ammonium salt, which can be at least one of tetrabutylammonium bromide, tetrabutylammonium hydroxide, tetrabutylammonium chloride, tetrabutylammonium iodide and tetrabutylammonium fluoride.

[0049] Step S2, washing, drying, pulverizing and roasting the molecular sieve with MEL structure synthesiz...

Embodiment 1

[0057] The sound-absorbing material of this embodiment includes MEL and MFI mixed-phase structural molecular sieves, and its preparation method is as follows:

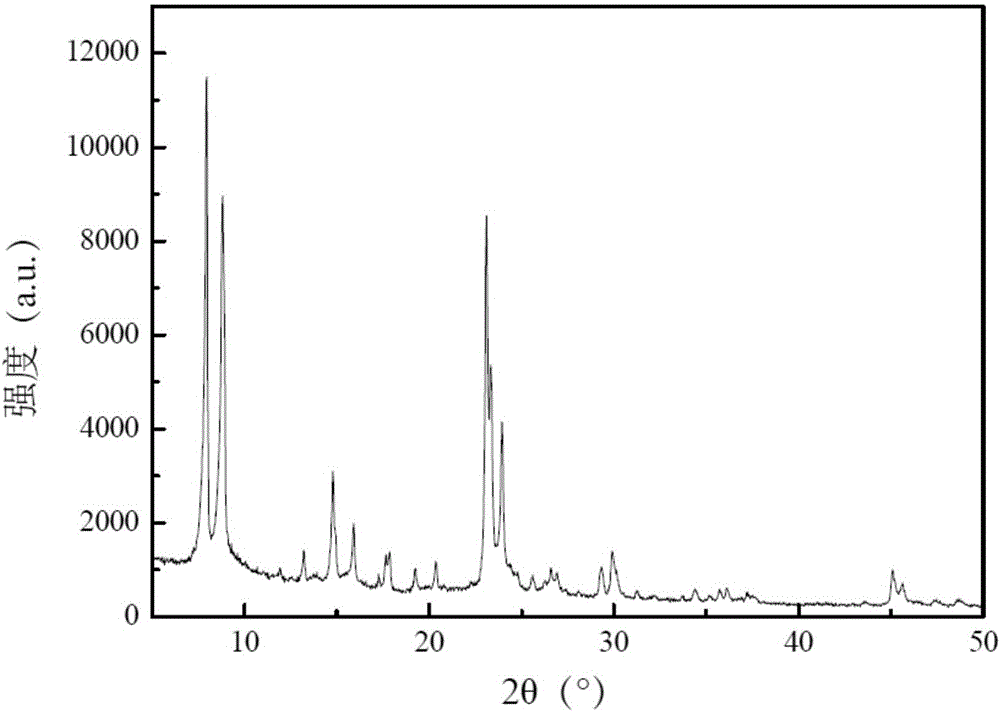

[0058] Silicon sources (including tetraethyl orthosilicate, silica sol and sodium silicate), aluminum sources (including aluminum nitrate, sodium metaaluminate and aluminum isopropoxide), alkali sources (including sodium hydroxide, potassium hydroxide and hydrogen Lithium oxide), the templating agent is tetrabutyl quaternary ammonium salt (at least one of tetrabutyl ammonium bromide, tetrabutyl ammonium hydroxide, tetrabutyl ammonium chloride, tetrabutyl ammonium iodide and tetrabutyl ammonium fluoride species) and the mol ratio of the hydrated silicon and aluminum elements are 250 MEL and MFI mixed-phase structure molecular sieves, and its XRD spectrum is as follows figure 2 As shown, the low-temperature nitrogen adsorption is characterized as Figure 5 As shown, the nitrogen adsorption and desorption at room temper...

Embodiment 2

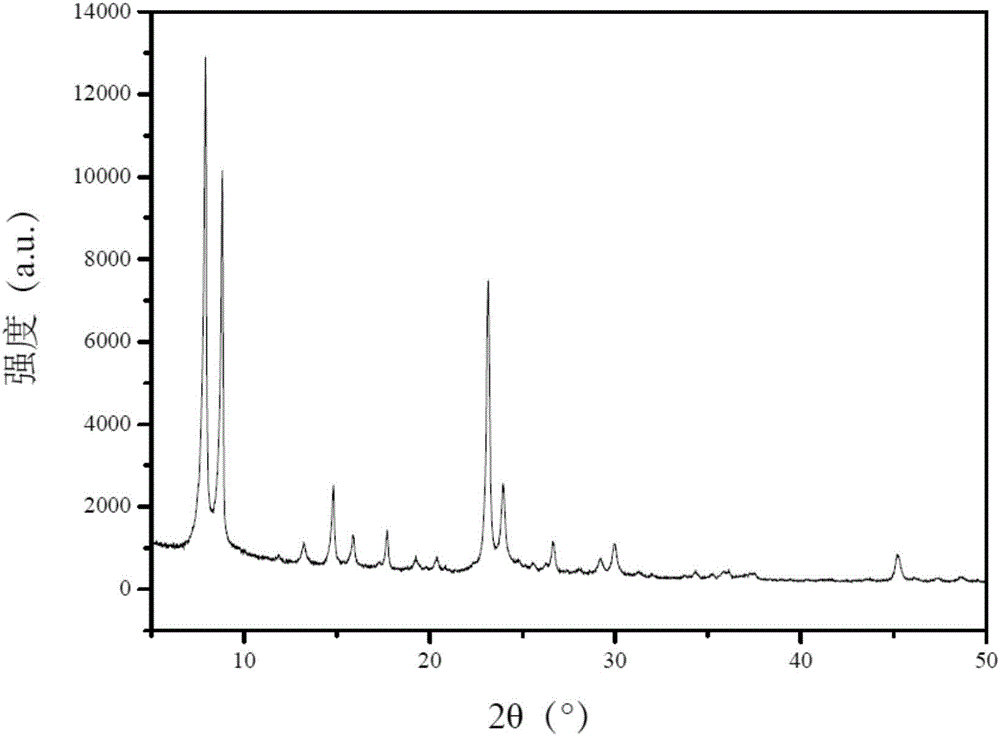

[0060] The sound-absorbing material of this embodiment includes MEL and MFI mixed-phase structural molecular sieves, and its preparation method is as follows:

[0061] Silicon source (including tetraethyl orthosilicate, silica sol and sodium silicate), iron source (including ferric nitrate, ferric sulfate and ferric chloride), alkali source (including sodium hydroxide, potassium hydroxide and lithium hydroxide) , the templating agent is tetrabutyl quaternary ammonium salt (at least one of tetrabutyl ammonium bromide, tetrabutyl ammonium hydroxide, tetrabutyl ammonium chloride, tetrabutyl ammonium iodide and tetrabutyl ammonium fluoride) and Hydrated molecular sieves with a molar ratio of silicon and iron elements of 300 in MEL and MFI mixed-phase structures, and their low-temperature nitrogen adsorption characteristics are as follows Figure 5 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com