Method for regenerating arsenic poisoning V2O5-WO3/TiO2 catalyst

A technology of V2O5-WO3 and catalysts, which is applied in the direction of catalyst regeneration/reactivation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., which can solve the limitations of industrialization promotion, expensive regeneration costs, and the degree of recovery Limited and other problems, to achieve the effect of low regeneration cost, easy access, and restoration of activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] inactive V 2 o 5 -WO 3 / TiO 2 Catalyst preparation:

[0020] Immersion Simulation V 2 o 5 -WO 3 / TiO 2 Catalyst As poisoning, using 1000ug / ml As standard solution, with the addition of As / V material ratio of 0.1, four honeycomb V 2 o 5 -WO 3 / TiO 2 The catalyst was impregnated in a beaker containing the dilution of the As standard solution for 6 hours with ultrasonic impregnation, left to stand for 6 hours, evaporated to dryness at 150°C, and finally calcined at 300°C for 6 hours in a muffle furnace under an air atmosphere to obtain simulated As Poisoned V 2 o 5 -WO 3 / TiO 2 catalyst.

Embodiment 2

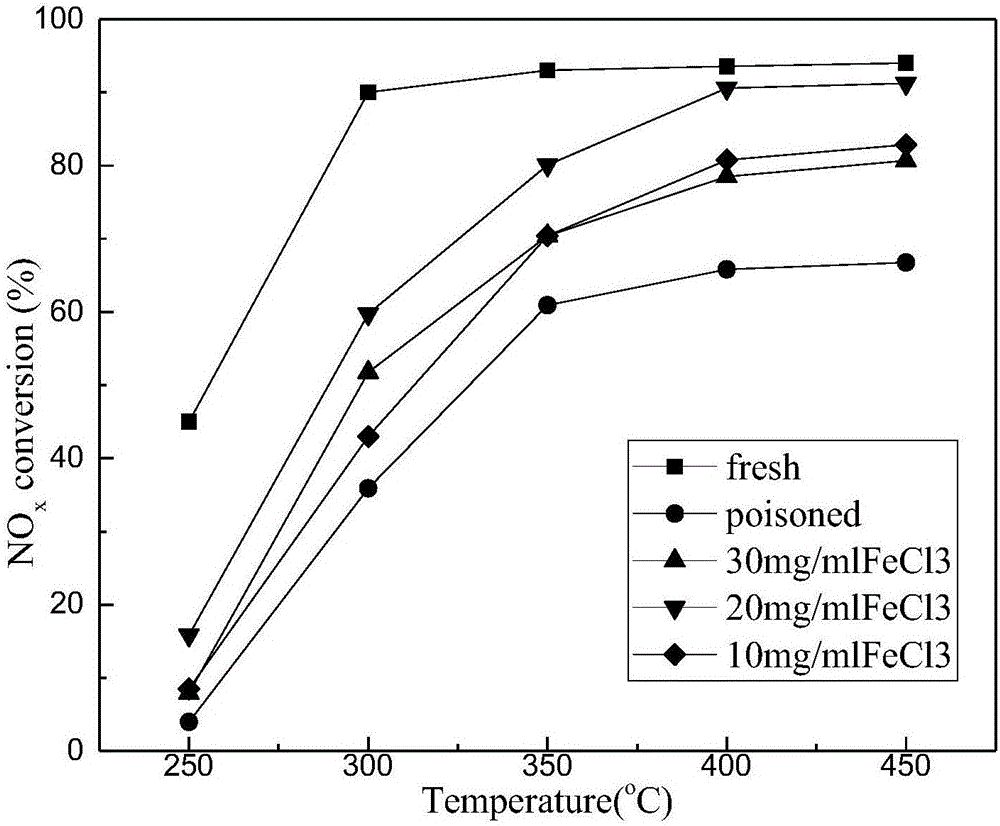

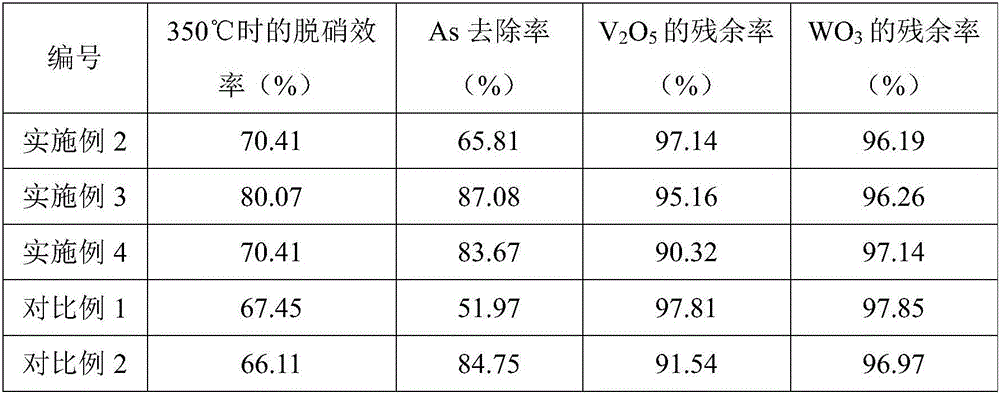

[0022] (1) the section in embodiment 1 is 25 * 25mm, and the number of holes is 3 * 3, and the honeycomb block shape deactivation V that length is 40mm 2 o 5 -WO 3 / TiO 2 After the catalyst is deashed, it is placed in deionized water and cleaned with ultrasonic assistance to remove the toxic components attached to the surface of the catalyst and in the pores. The cleaning time is 60 minutes, the ultrasonic power is 300W, and it is dried at room temperature before use;

[0023] (2) 10g of FeCl 3 Dissolve the powder in 100ml deionized water to make 10mg / ml FeCl 3 Aqueous solution, place the dry deactivated catalyst prepared in step (1) in the solution for ultrasonic treatment for 30 minutes, then let it stand for 6 hours, take it out and drain;

[0024] (3) Take out the catalyst drained in step (2), soak and clean it in water for 3 hours in an ultrasonic cleaner, dissolve the regeneration solution and poisoning components remaining on the surface of the catalyst, then place ...

Embodiment 3

[0026] Change (2) step into the FeCl of 20g in embodiment 2 3 Dissolve the powder in 100ml deionized water to make 20mg / ml FeCl 3 aqueous solution, the rest of the conditions and steps remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com