Molybdenum disulfide nano-catalyst preparation method, catalyst and application thereof

A nano-catalyst and molybdenum disulfide technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as poor dispersion of organic solvents, high requirements for experimental conditions, and large product sizes. Achieve the effect of improving dispersion, simple operation process and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

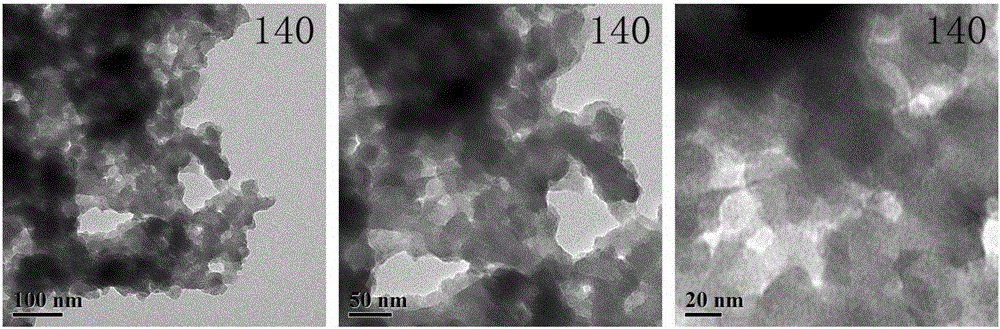

[0034] Weigh 199.6mg of ammonium thiomolybdate [(NH 4 ) 2 MoS 4 ] uniformly disperse it in 100mL of anhydrous methanol under the assistance of ultrasound, then add 380.2mg of PVP (polymerization degree = 30), and stir in a constant temperature water bath at 60°C for 0.5h, the system becomes a uniform transparent red solution . Add 1mL of hydrazine hydrate (80%) dropwise to the system, stir evenly, and transfer about 65mL into a 100mL hydrothermal reaction kettle. After sealing, the autoclave was placed in a 140°C oven. After maintaining the constant temperature for 3 hours, it was cooled naturally. The reacted product is successively washed with absolute ethanol and acetone, centrifuged three times, and vacuum-dried to obtain molybdenum disulfide nanospheres. And use it as a catalyst to evaluate its catalytic performance for anthracene hydrogenation, denoted as S1.

[0035] Depend on figure 1 , it can be found that the product obtained at a constant temperature of 140°C f...

Embodiment 2

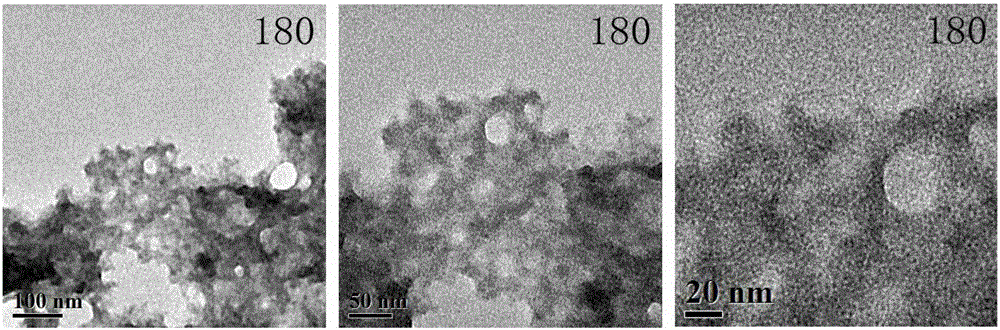

[0038] Weigh 207mg of ammonium thiomolybdate [(NH 4 ) 2 MoS 4 ] uniformly disperse it in 100mL of anhydrous methanol under the assistance of ultrasound, then add 853mg of PVP (polymerization degree=30), after stirring in a constant temperature water bath at 60°C for 0.5h, the system becomes a uniform transparent red solution. Add 1.25 mL of hydrazine hydrate (80%) dropwise to the system, stir evenly, and then transfer about 65 mL into a 100 mL hydrothermal reaction kettle. After sealing, the kettle was placed in a 180°C oven. After maintaining the constant temperature for 3 hours, it was cooled naturally. The reacted product was successively washed with absolute ethanol and acetone, centrifuged three times, and vacuum-dried to obtain spherical nanomolybdenum disulfide, denoted as S2. Such as figure 2 .

Embodiment 3

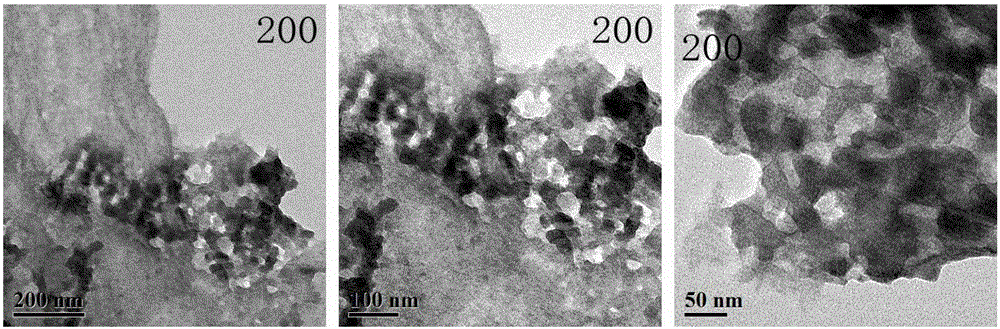

[0040] Weigh 242mg of ammonium thiomolybdate [(NH 4 ) 2 MoS 4 ] uniformly disperse it into 100mL of anhydrous methanol under the assistance of ultrasound, then add 0.118g of PVP (polymerization degree=30), and stir in a constant temperature water bath at 60°C for 0.5h, the system becomes a uniform transparent red solution . Add 1.5 mL of hydrazine hydrate (80%) dropwise to the system, stir evenly, and then transfer about 65 mL into a 100 mL hydrothermal reaction kettle. After sealing, the kettle was placed in a 200°C oven. After maintaining the constant temperature for 3 hours, it was cooled naturally. The reacted product was successively washed with absolute ethanol and acetone, centrifuged three times, and vacuum-dried to obtain spherical nanomolybdenum disulfide, denoted as S1. Such as image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com