Preparation method of indium oxide nano-powder

A nano-powder and indium oxide technology, which is applied in chemical instruments and methods, nanotechnology, inorganic chemistry, etc., can solve the problems of long preparation process cycle, complicated process, and environmental pollution, so as to achieve large-scale controllable production and avoid Emission of pollutants, the effect of simple preparation means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Mix 90g of stearic acid and 12g of indium particles with a purity of 5N, continue to pass in 1L / min of argon gas, heat to 170°C while stirring, and keep for 10h until the indium particles are completely dissolved, and then cool to obtain organic Indium compounds;

[0032] (2) Add 13.6g of hydrogen peroxide and 3.6g of deionized water to the organic indium compound prepared in step (1), mix them and place them in a supercritical hydrothermal reactor for reaction, the reactor heating temperature is 290°C, and the reaction time is 3h, after the completion of the reaction, cool to room temperature, and obtain the reaction product by filtration;

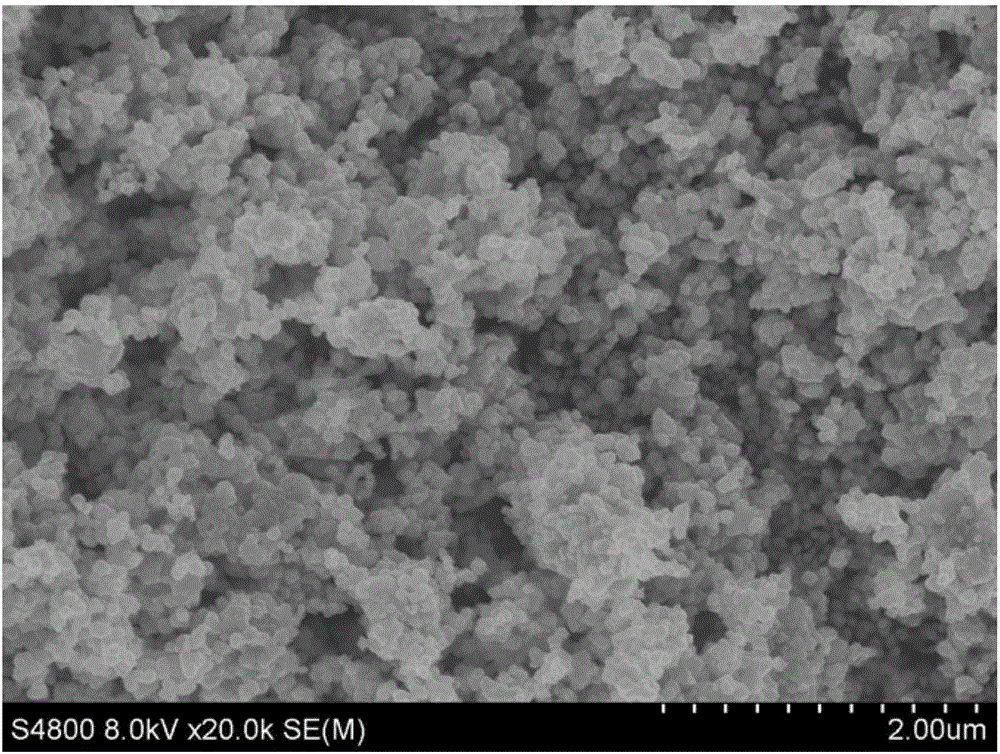

[0033] (3) Calcining the reaction product in step (2) at 400°C in the air for 2 hours to obtain indium oxide nanopowder, the SEM characterization picture is as follows figure 1 As shown, the particle size of the obtained indium oxide nanopowder is 50-200 nm, the distribution is uniform, and the phase is a cubic phase structure...

Embodiment 2

[0035] (1) Mix 70g of capric acid and 12g of indium wire with a purity of 4N, continuously pass in 2L / min of argon gas, heat to 200°C while ultrasonically stirring, and keep it for 6h until the indium wire is completely dissolved, then cool to obtain organic Indium compounds;

[0036] (2) Add 15.1g of hydrogen peroxide and 3.9g of deionized water to the organic indium compound prepared in step (1), mix them and place them in a supercritical hydrothermal reactor for reaction, the reactor heating temperature is 350°C, and the reaction time is 2.5h, after the completion of the reaction, cool to room temperature, and obtain the reaction product by filtration;

[0037] (3) Calcining the reaction product in step (2) in air at 500° C. for 2.5 hours to obtain indium oxide nanopowder with a particle size of 100-300 nm, uniform distribution, and a cubic phase structure.

Embodiment 3

[0039] (1) Mix 85g of capric acid and 12g of indium particles with a purity of 4N, continuously feed 2L / min of titanium dioxide, heat to 270°C while stirring, and keep for 2h until the indium particles are completely dissolved, and cool to obtain an organic indium compound ;

[0040] (2) Add 11.5g of hydrogen peroxide and 2.0g of deionized water to the organic indium compound prepared in step (1), mix them and place them in a supercritical hydrothermal reactor for reaction, the reactor heating temperature is 450°C, and the reaction time is 1.5h, after the completion of the reaction, cool to room temperature, and obtain the reaction product by filtration;

[0041](3) Calcining the reaction product in step (2) in air at 650° C. for 2 hours to obtain indium oxide nanopowder with a particle size of 300-400 nm, uniform distribution, and a cubic phase structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com