Heavy-duty anticorrosive solvent-free epoxy basalt scale coating and preparation method thereof

A basalt, solvent-free technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of high content, insufficient wear resistance, insufficient acid and alkali resistance, etc., achieve excellent coating performance and reduce corrosion speed , Outstanding anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

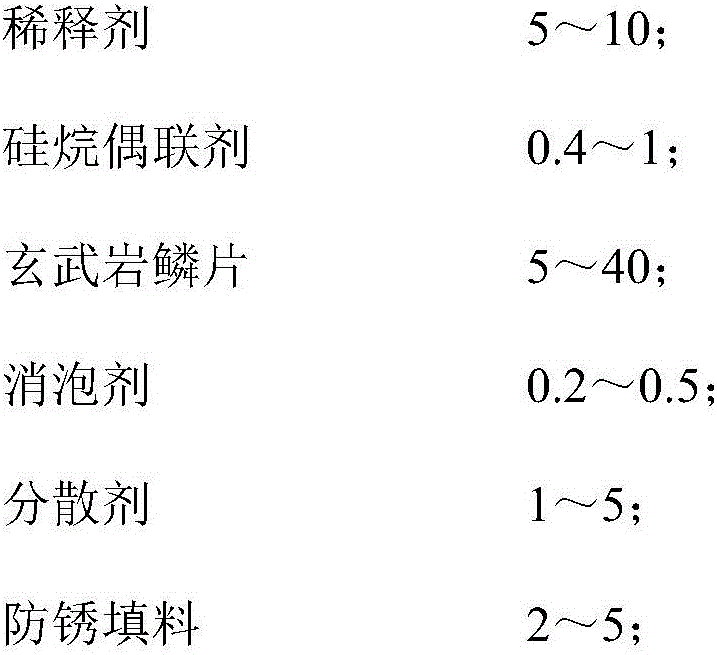

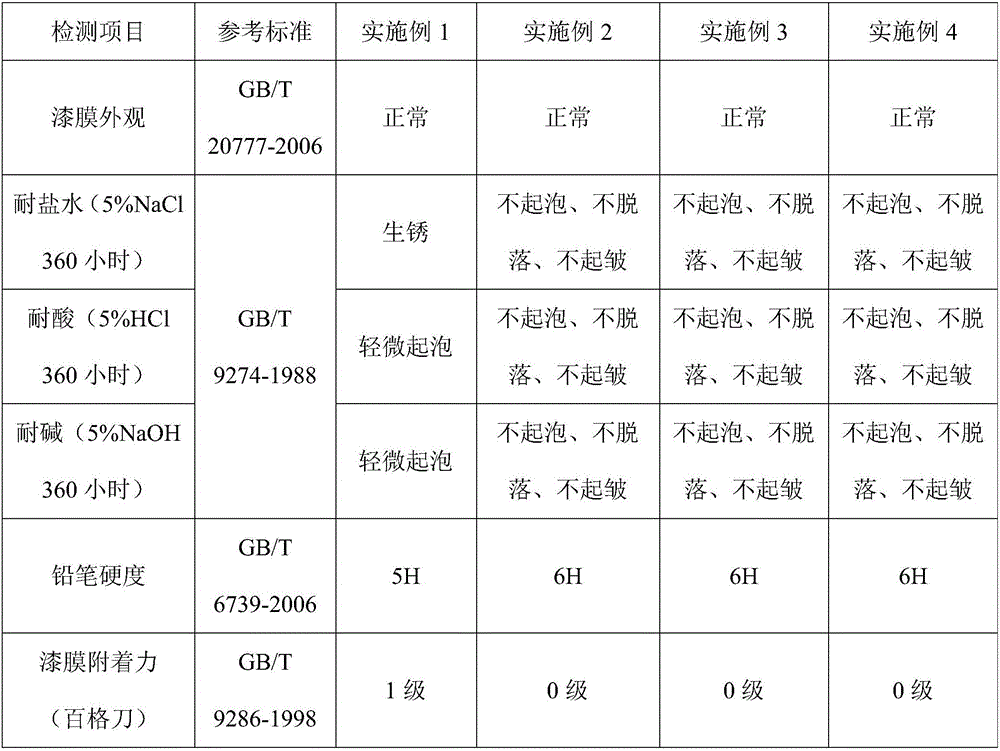

[0035] Parts by mass of group A: bisphenol A epoxy resin E-51, 40 parts by mass, 0.2 parts by mass of BYK-A530 defoamer produced by BYK, 1 part by mass of Disperbyk163 dispersant produced by BYK, 1,4- 5 parts by mass of butanediol diglycidyl ether diluent, 0.4 parts by mass of silane coupling agent gamma-aminopropyltriethoxysilane, 5 parts by mass of 200 mesh basalt flakes, 2 parts by mass of aluminum tripolyphosphate as antirust filler; Component B: 10 parts by mass of phenalkamine curing agent, 5 parts by mass of 1,4-butanediol diglycidyl ether diluent.

[0036] The preparation process is as follows:

[0037] 1) Add defoamer, silane coupling agent, dispersant, and diluent to epoxy resin, stir at 300-500 rpm for 15-20 minutes, and let stand for 24 hours to obtain a mixed solution.

[0038] 2) Add basalt flakes and antirust fillers to the mixture obtained in step 1), stir at 300-500 rpm for 10-20 minutes, and then ultrasonically disperse for 5-10 minutes to obtain component A...

Embodiment 2

[0042] Parts by mass of group A: 50 parts by mass of bisphenol F epoxy resin, 0.5 parts by mass of BYK-A088 defoamer produced by BYK, 5 parts by mass of Disperbyk162 dispersant produced by BYK, 10 parts by mass of benzyl glycidyl ether diluent , 1 mass part of silane coupling agent γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 20 mass parts of 325 mesh basalt flakes, 3 mass parts of antirust filler zinc phosphate; component B: polyamide 25 parts by mass of curing agent, 5 parts by mass of benzyl glycidyl ether diluent.

[0043] The preparation process is as follows:

[0044] 1) Add defoamer, silane coupling agent, dispersant, and diluent to epoxy resin, stir at 300-500 rpm for 15-20 minutes, and let stand for 24 hours to obtain a mixed solution.

[0045] 2) Add basalt flakes and antirust fillers to the mixture obtained in step 1), stir at 300-500 rpm for 10-20 minutes, and then ultrasonically disperse for 5-10 minutes to obtain component A.

[0046] 3) Mix the curing agent and...

Embodiment 3

[0049] Parts by mass of group A: bisphenol A epoxy resin E-44, 45 parts by mass, 0.3 parts by mass of Defom5300 defoamer produced by Deqian Chemical Company, 4 parts by mass of Disperbyk164 dispersant produced by BYK, 1,6-hexylene 8 parts by mass of alcohol diglycidyl ether thinner, 0.8 parts by mass of silane coupling agent γ-(methacryloyloxy)propyltrimethoxysilane, 30 parts by mass of 500 mesh basalt flakes, antirust filler calcium phosphomolybdate 4 parts by mass; component B includes: 10 parts by mass of phenalkamine curing agent, 10 parts by mass of 1,6-hexanediol diglycidyl ether diluent.

[0050] The preparation process is as follows:

[0051] 1) Add defoamer, silane coupling agent, dispersant, and diluent to epoxy resin, stir at 300-500 rpm for 15-20 minutes, and let stand for 24 hours to obtain a mixed solution.

[0052] 2) Add basalt flakes and antirust fillers to the mixture obtained in step 1), stir at 300-500 rpm for 10-20 minutes, and then ultrasonically dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com