Extensible semiconductor resistive flexible gas sensor and preparation method thereof

A gas sensor and resistive technology, applied in the field of stretchable semiconductor resistive flexible gas sensor and its preparation, can solve the problems of slow response/recovery time, poor flexibility of rigid substrate, low gas-sensing response sensitivity, etc., and achieve enhanced long-term Stability, low cost, and the effect of improving gas sensing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

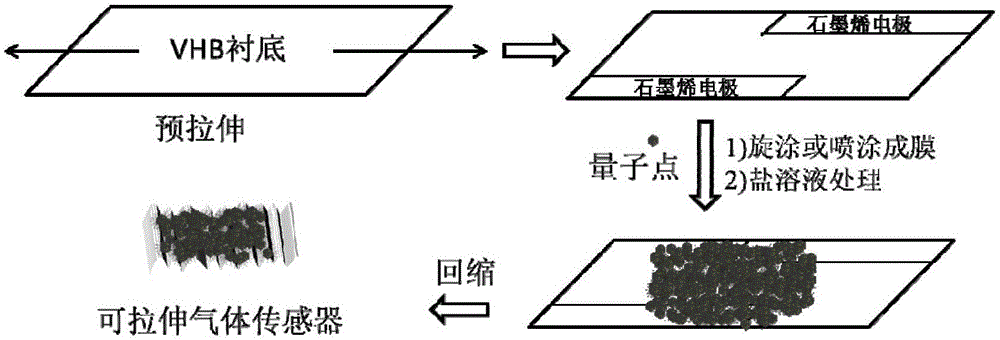

[0028] A stretchable semiconductor resistive gas sensor with thin film micro-wrinkle structure and its preparation method according to the embodiment of the present invention, such as figure 1 As shown, the specific steps are as follows:

[0029] (1) Fix the flexible insulating substrate VHB unidirectional pre-stretching 0-200% on the rigid base (optional);

[0030] (2) The graphene paper prepared by the suction filtration method is used as a sensor electrode and transferred to the VHB to prepare a patterned graphene electrode;

[0031] (3) Colloidal quantum dot solution is coated on the VHB substrate with patterned graphene electrode, make it form a film evenly, the film forming method includes methods such as spin coating, drop coating, spraying, printing;

[0032] (4) Treat the quantum dot film with a short-chain salt solution ligand to replace the long-chain oleic acid oleylamine ligand coated on the film surface, so that the target gas molecules are more likely to contac...

Embodiment 1

[0036] Embodiment 1: The preparation of a stretchable semiconductor resistive gas sensor with a pre-stretching degree of 0 specifically includes the following steps:

[0037] (1) Preparation of PbS colloidal quantum dot solution. PbO is used as the lead source, bistrimethylsilathane (TMS) is used as the sulfur source, and colloidal chemical method is used to generate it.

[0038] Specifically, 0.9 g (4 mmol) PbO was dissolved in 3 mL oleic acid (OA) and 17 mL octadecene (ODE) under nitrogen atmosphere and heated to 90 °C to prepare the precursor of lead oleate as the lead source. After evacuating for 8 hours, the temperature of the precursor was raised to 120°C. Dissolve 180 μL (1 mmol) TMS into 10 mL ODE as a sulfur source. Rapidly inject the sulfur source into the lead source at 120°C, and after the color of the reaction system turns black (about 15s), put the solution into cold water to rapidly drop the temperature to room temperature. Add an appropriate amount of aceton...

Embodiment 2

[0046] Embodiment 2: The preparation of a stretchable semiconductor resistive gas sensor with a pre-stretching degree of 80% specifically includes the following steps:

[0047] Implementation steps (1) (2) (4) (5) (6) are identical with embodiment 1, and concrete implementation steps (3) (7) are as follows:

[0048] (3) 80% of the VHB substrate is pre-stretched in one direction and fixed on the glass substrate;

[0049] (7) Put it in the air for 30-45s and wait for the quantum dot film to dry, then slowly retract the VHB substrate at a rate of 1cm / s to obtain a semiconductor resistive gas sensor with a film micro-wrinkled structure and stretchable properties .

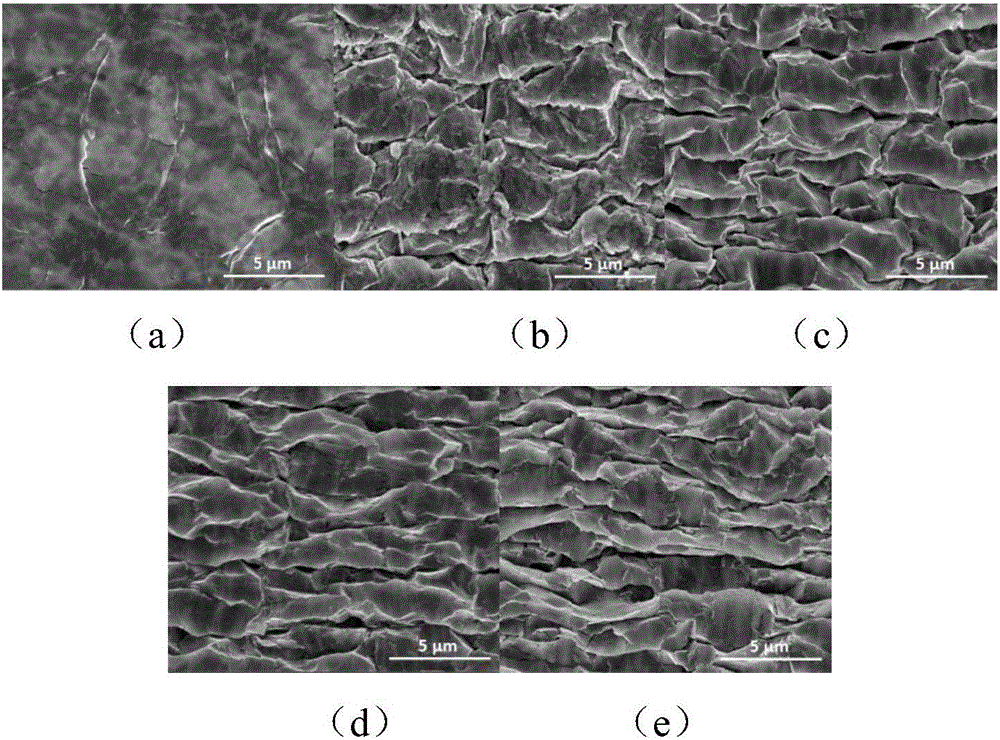

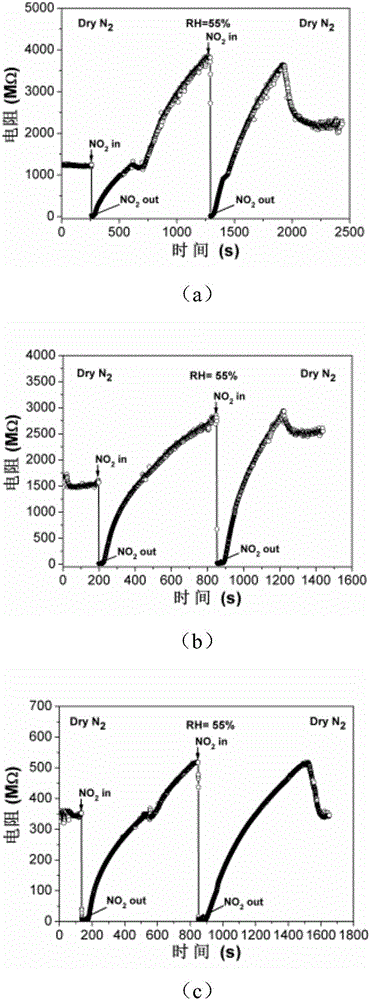

[0050] The wrinkle degree of the gas sensor prepared in Example 2 of the present invention and the response sensitivity to 50 ppm nitrogen dioxide at room temperature and different humidity conditions were tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com