Graphene base TiO2 nano-composite material capable of removing humic acid in rural drinking water, and preparation method thereof

A nanocomposite material and graphene-based technology, applied in water/sewage treatment, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as limited ability to absorb visible light, difficulty in recycling and reuse, and achieve high cost performance , low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

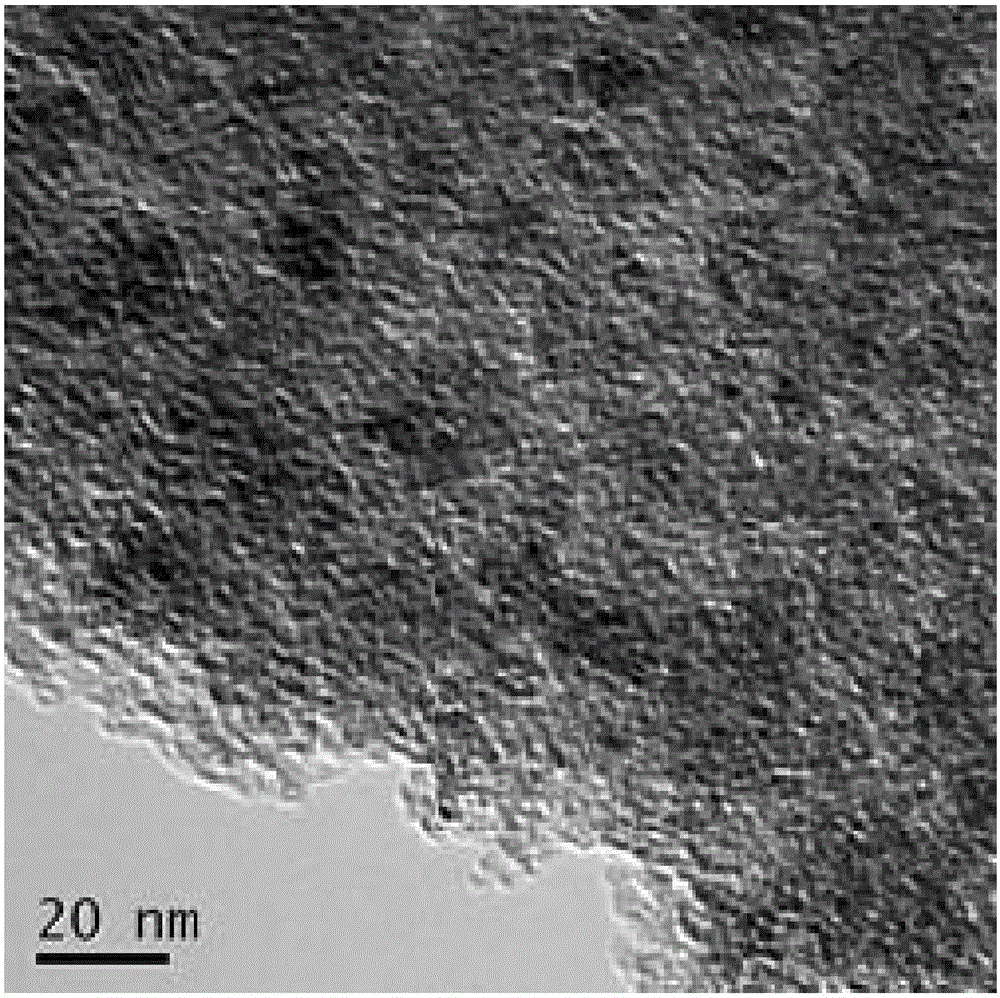

[0043] Preparation of a graphene-based TiO for the removal of humic acid in rural drinking water 2 A nanocomposite material comprising the steps of:

[0044] (1) Put the round-bottomed beaker in an ice-water bath, add 23ml of ice-concentrated sulfuric acid, and add 0.5g of sodium nitrate, stir for 0.5h until the sodium nitrate powder is suspended in the solution; add 0.5g of graphite powder, and continue magnetic stirring for 1h to obtain mixture;

[0045] (2) Slowly add 3g of potassium permanganate to the mixed solution obtained in step (1), and stir for 1 hour in a water bath at 35°C to form a thick slurry; slowly add 40mL of deionized water, stir the solution for 30min, and the temperature rises to 90°C Add 100mL of deionized water, slowly add 3mL of 30wt% hydrogen peroxide, and stir for 30min; centrifuge the mixed solution, remove the supernatant, add 3wt% hydrochloric acid solution and deionized water to the centrifuge tube for centrifugal washing until the pH of the fil...

Embodiment 2

[0055] (1) Put the round-bottomed beaker in an ice-water bath, add 23ml of ice-concentrated sulfuric acid, and add 0.5g of sodium nitrate, stir for 1 hour until the sodium nitrate powder is suspended in the solution; add 0.5g of graphite powder, and continue magnetic stirring for 1 hour to obtain a mixture solution;

[0056] (2) Slowly add 3g of potassium permanganate to the mixed solution obtained in step (1), and stir for 1 hour in a water bath at 35°C to form a thick slurry; slowly add 40mL of deionized water, stir the solution for 30min, and the temperature rises to 90°C Add 100mL of deionized water, slowly add 3mL of 30wt% hydrogen peroxide, and stir for 30min; centrifuge the mixed solution, remove the supernatant, add 3wt% hydrochloric acid solution and deionized water to the centrifuge tube for centrifugal washing until the pH of the filtrate is 6~7, the aqueous solution of graphite oxide is obtained;

[0057] (3) Disperse graphite oxide in an aqueous solution and disp...

Embodiment 3

[0061] (1) Put the round-bottomed beaker in an ice-water bath, add 23ml of ice-concentrated sulfuric acid, and add 0.5g of sodium nitrate, stir for 2 hours until the sodium nitrate powder is suspended in the solution; add 0.5g of graphite powder, and continue magnetically stirring for 1 hour to obtain a mixed solution;

[0062] (2) Slowly add 3g of potassium permanganate to the mixed solution obtained in step (1), and stir for 1 hour in a water bath at 35°C to form a thick slurry; slowly add 40mL of deionized water, stir the solution for 30min, and the temperature rises to 90°C Add 100mL of deionized water, slowly add 3mL of 30wt% hydrogen peroxide, and stir for 30min; centrifuge the mixed solution, remove the supernatant, add 3wt% hydrochloric acid solution and deionized water to the centrifuge tube for centrifugal washing until the pH of the filtrate is 6~7, the aqueous solution of graphite oxide is obtained;

[0063] (3) Disperse graphite oxide in an aqueous solution and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com