Composite chitosan flocculant for treating desulfurization wastewater, preparation method and application

A technology of desulfurization wastewater and chitosan, which is applied in the direction of water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems that cannot meet the treatment requirements, desulfurization wastewater cannot meet the standard discharge, etc., and achieve faster adsorption Good flocculation effect and strong flocculation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Chitosan is dissolved in the acetic acid solution of 1% (volume), after dissolving completely, form the chitosan solution of 2% (mass), the chitosan solution is heated to 80 ℃, in the situation of continuous stirring Next, add 0.5% iron sulfate of chitosan mass and magnesium sulfate of 0.5% chitosan mass in turn, continue to stir for 2 hours, stir evenly, then put it into an oven for drying, dry at 90°C and then grind.

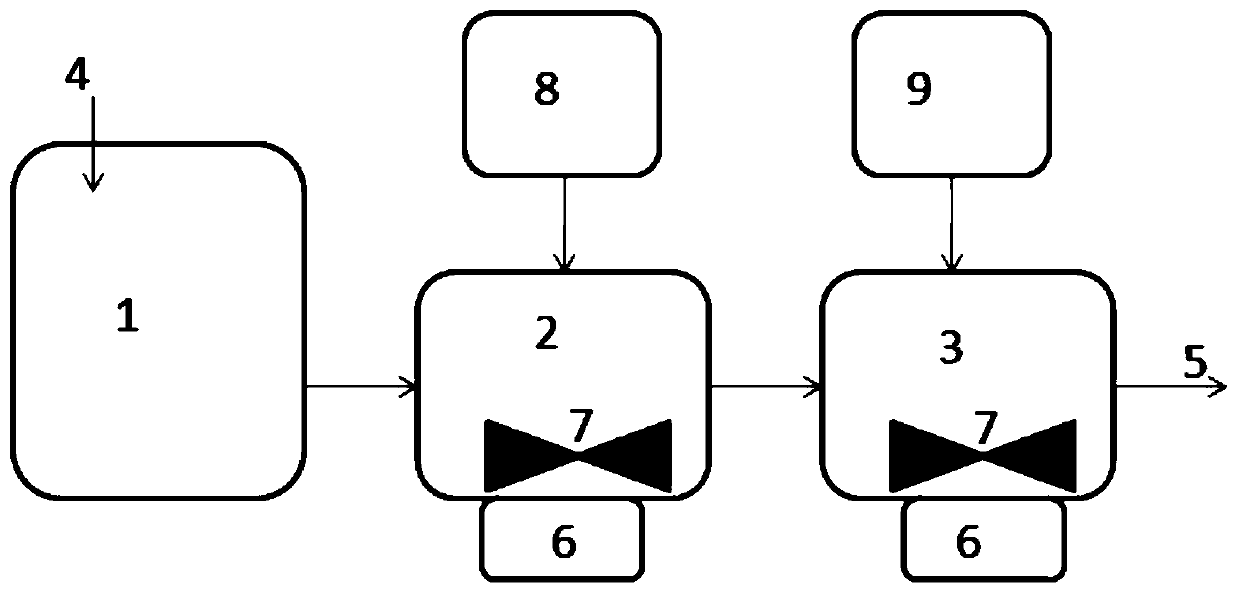

[0052] 2. Take the desulfurization wastewater from Huaneng Jiaxiang Power Plant. The desulfurization wastewater is introduced into the neutralization tank, and lime is added through the lime inlet. Under the condition of continuous stirring, the lime is added until the pH reaches 8.0. After the stirring stops and the lime settles, the wastewater is introduced into the flocculation tank.

[0053] 3. Introduce the wastewater into the flocculation tank, stir the wastewater at a speed of 100rpm, add flocculant according to the mass ratio of 1:10000, cont...

Embodiment 2

[0058] 1. The preparation steps of the flocculant are the same as in Example 1.

[0059] 2. Take the desulfurization wastewater from Huadian Zouxian Power Plant, and the lime treatment process is the same as in Example 1.

[0060] 3. The flocculation treatment process is the same as in Example 1.

[0061] 4. The water quality analysis process is the same as in Example 1.

[0062] The test results are shown in Table 2.

[0063] Table 2

[0064] Project indicators Raw water (ppm) Lime treatment (ppm) Flocculation treatment (ppm) suspended matter 7900 1940 28 Copper ion content 0.229 0.036 not detected Cadmium ion content 0.331 0.117 0.011 Zinc ion content 0.154 0.081 0.020

Embodiment 3

[0066] 1. The preparation steps of the flocculant are the same as in Example 1.

[0067] 2. Take the desulfurization wastewater from Huaneng Huangtai Power Plant, and the lime treatment process is the same as in Example 1.

[0068] 3. The flocculation treatment process is the same as in Example 1.

[0069] 4. The water quality analysis process is the same as in Example 1.

[0070] The test results are shown in Table 3.

[0071] table 3

[0072] Project indicators Raw water (ppm) Lime treatment (ppm) Flocculation treatment (ppm) suspended matter 9300 1770 28 Copper ion content 0.204 0.028 not detected Nickel content 0.177 0.124 0.022 Zinc ion content 0.335 0.177 0.022

[0073] The present invention mainly constructs a desulfurization wastewater upgrading process based on composite chitosan as a flocculant, and realizes the desulfurization wastewater of multiple power plants on the basis of reducing the original chemical do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com