Electrochemical hardness-removing and turbidity-removing integrated device for processing coal gasification grey water or black water, method for processing coal gasification grey water or black water and application of electrochemical hardness-removing and turbidity-removing integrated device

An electrochemical and electrochemical reaction technology, applied in chemical instruments and methods, sludge treatment, sedimentation treatment, etc., can solve the problems of large amount of sludge, inability to effectively solve scaling and fouling, and long sedimentation time, and achieve Effect of reducing fouling tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

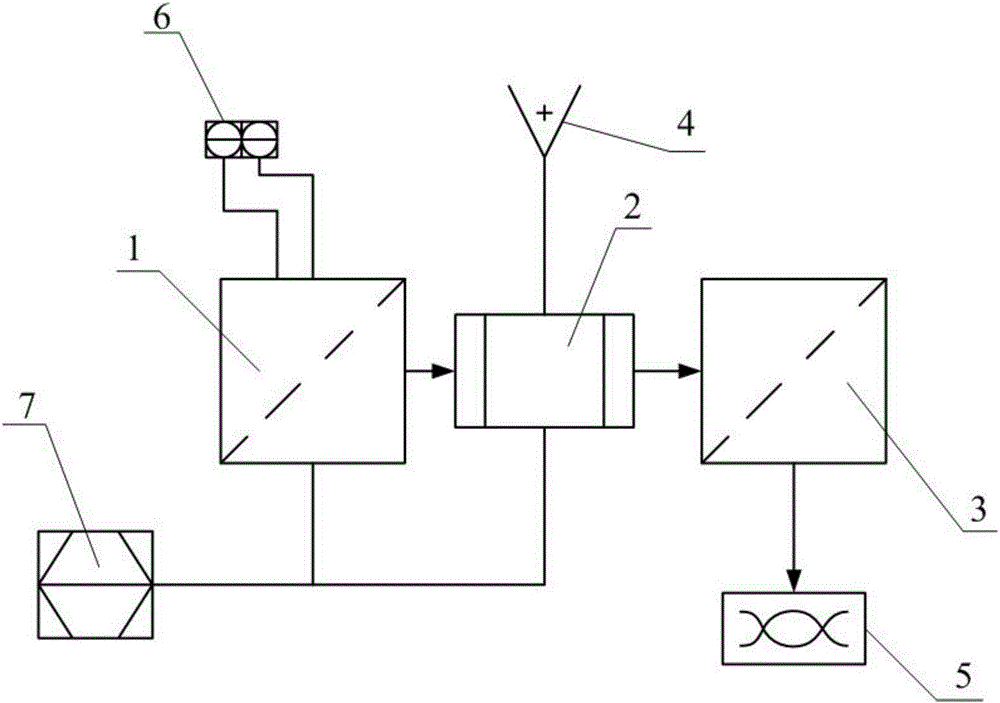

[0055] Such as figure 1 As shown, this embodiment provides an integrated electrochemical device for removing hardness and turbidity for treating coal gasification gray water or black water. The device includes sequentially connected electrochemical reaction zone 1, alkalinity adjustment zone 2 and precipitation zone 3.

[0056] The electrochemical integrated device for removing hardness and turbidity also includes an alkalinity dosing device 4, a sludge treatment device 5, a power module 6 and a detection control module 7, and the alkalinity dosing device 4 is connected to the alkalinity adjustment area 2 , the sludge treatment device 5 is connected to the precipitation area 3, the power supply module 6 is connected to the electrochemical reaction area 1, and the detection control module 7 is connected to the electrochemical reaction area 1 and the alkalinity adjustment area 2.

[0057] Wherein, the sludge treatment device 5 is a plate and frame mud compactor, the power templ...

Embodiment 2

[0059] This embodiment provides an integrated electrochemical device for removing hardness and turbidity for processing coal gasification gray water or black water. In addition to the sludge treatment device 5, the device is a screw compactor, and the power supply template 6 adopts a pulse power supply. The material of the electrochemical reactor set in the electrochemical reaction zone 1 is metal aluminum, and the precipitation zone 3 adopts a slanting plate precipitation, and the material of the sloping plate is glass steel, and other structures are the same as the device in embodiment 1.

Embodiment 3

[0061] This embodiment provides an integrated electrochemical device for removing hardness and turbidity for treating coal gasification gray water or black water. In addition to the sludge treatment device 5, the device is a vacuum belt machine, and the power supply template 6 adopts an AC power supply. The sedimentation area 3 adopts the inclined tube type precipitation, and the material of the inclined tube is polytetrafluoroethylene, a temperature-resistant organic material, and the other structures are the same as the device in the embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com